Graphite isn't just for lubrication and No. 2 pencils anymore.

Graphite isn't just for lubrication and No. 2 pencils anymore.

Today it's a key ingredient in many industries, and the finest graphite is essential for nuclear power and semiconductors.

Toyo Tanso Japan was the first company to achieve mass production of this fine-grade isotropic graphite. Their subsidiary, Toyo Tanso USA, manufactures isotropic graphite and also provides graphite-related silicon carbide surface treatments to customers.

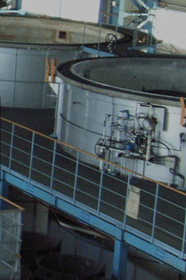

For this process Toyo Tanso USA needed a rugged control system with plenty of I/O options. The multiple vessels involved in the process require precise control of interacting systems in a busy, tough industrial setting.

Toyo Tanso looked for a system that could provide distributed control for maintaining critical setpoints and also be easily programmed and deployed.

A bonus? The ability to alert operators to dangerous gases via smartphone.

Learn more about their process and system of choice in our new case study.