Learn how cutting-edge industrial devices using artificial intelligence (AI) are saving mining companies thousands through early leak detection.

Are you in an industry with strict regulations that require constant remote monitoring? That's what several companies are facing in Peru's mining region.

With miles of mining pipelines in Peru, national regulations require continuous monitoring to prevent spills and ensure safe operation. For mining companies, this means the search is on for practical, cost effective, and sustainable solutions to meet these standards.

Learn how OptoPartner PK Soluciones took on the challenge of stopping pipeline leaks before they stop production.

Read More

Topics:

Case studies,

Node-RED,

CODESYS,

groov EPIC,

python,

AI,

mining

New Who's groovin' video series lets you preview a variety of industrial application challenges and solutions.

When you’re working through a control or monitoring problem, it helps to see how someone else already solved something similar.

That's the idea behind a new short video series called Who's groovin'.

Get a sneak peek.

Read More

Topics:

Case studies,

Videos,

groov EPIC,

groov RIO

Here's your chance to experience the 2025 Ignition Community Conference on your schedule.

The wait is over! You no longer need a registration pass to learn about the Ignition projects showcased in the 2025 Ignition Community Conference. Inductive Automation announced that all conference sessions, keynotes, panels, and the Build-a-Thon are now streaming on demand.

This is a great opportunity to learn more about Ignition software, see what it can do for your applications, and watch Opto 22's session on machine monitoring featuring our case study with MTNA. Oh, and watch the world-famous competitive SCADA event: The ICC Build-a-Thon!

If you did attend ICC 2025 in Sacramento this last September, here's your chance to revisit standout moments, catch up on sessions you missed, or dive deeper into the latest ideas shaping the Ignition ecosystem. You can access expert insights, real-world use cases, and technical deep dives—on your own schedule.

Read More

Topics:

Case studies,

groov EPIC,

Ignition,

Ignition Community Conference,

machine monitoring

New case study shows you a simple way to digitally transform manual, disconnected underground systems into smart systems with full-scale, remote visibility.

Do you work on industrial applications in hazardous environments, where one failure can lead to immediate and severe consequences?

OptoPartner Surety Automation has decades of experience in mining and process industries, and is no stranger to handling the challenges that come with these types of projects.

Read about their latest application success story, with a major gold producer in northern Nevada.

Read More

Topics:

Case studies,

CODESYS,

Ignition,

groov RIO

Watch the Fall 2025 CODESYS Tech Talk for a high-level overview of how CODESYS programming is used in today's industrial automation applications.

Are you challenged to select the programming tool that best suits your application? We get it, and that's why you have programming options to choose from in groov EPIC and groov RIO products.

One of the many options is the CODESYS Development System, which lets you use all the standard tools and IEC 61131-3 programming methods, like ladder logic or sequential function charts.

Opto 22 Director of Technical Marketing, Dan White, recently presented a customer application in the oil and gas industry that explains how CODESYS with groov RIO transformed a controls system. Watch the Fall 2025 CODESYS Tech Talk for the full story.

Read More

Topics:

Case studies,

Webinars,

Oil & gas,

CODESYS,

groov RIO

Learn from PermaCool's experience of scaling custom chillers with smarter automation and remote diagnostics.

Are you dealing with the challenges that come with a third-party or outsourced controls system?

What happens when you need to troubleshoot or make a repair, but you don't have access to the controls?

PermaCool, a busy OEM in the plant extraction industry, encountered a bottleneck when its outsourced components couldn't keep pace. Read this new case study to see how they overcame the limitations they faced and were able to push the boundaries of what they could accomplish.

Read More

Topics:

Case studies,

OEM,

groov EPIC

Curious how others are solving industrial control and automation challenges similar to yours? Recent case studies show you how.

Whether it’s incompatible systems, saving costs and improving operations, or dealing with end-of-life products, application stories from customers in your field or other industries can give you ideas for solutions.

Take a look at the most recent case studies in the Opto 22 case study library—we’ve added quite a few over the past year. You can read each story on the web page or download it as a PDF document.

Here are a few case study highlights, so you can see how customers worldwide are solving current industrial automation challenges.

Read More

Topics:

Case studies,

groov EPIC,

groov RIO

New Automation World article explains how a tier-one automotive supplier connected legacy injection molding machines for less than $1,000 per machine without writing a single line of code or replacing PLCs.

In case you missed this year's Ignition Community Conference, David Greenfield (Automation World Editor-in-Chief) provides an excellent recap of a "machine monitoring" session in his latest article.

Hear key takeaways from Dan White's presentation on cost-effective ways to get data from your brownfield devices and transform legacy manufacturing to smart machine monitoring.

Then see first-hand how Moriroku Technology North America (MTNA) implemented these machine monitoring tips to elevate their operations.

Read More

Topics:

Case studies,

Automation World,

Ignition,

Ignition Community Conference,

groov RIO,

machine monitoring

See how a simple plan using new technology in a rugged environment provided control and visibility over all operations.

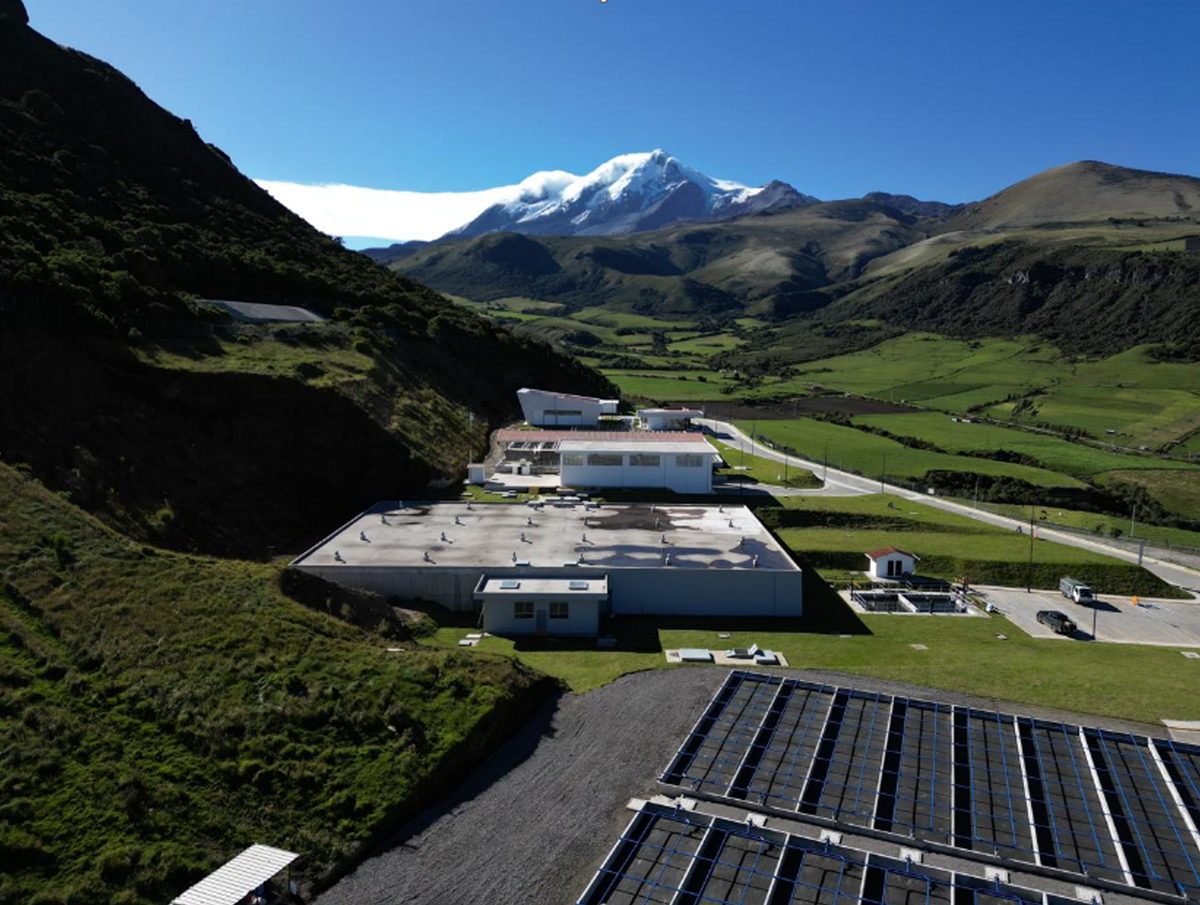

When local leaders in Northern Ecuador commissioned a new regional water treatment plant to supply clean water to 300,000 people across five municipalities, the contractor recognized that modern SCADA and automation were essential for managing the water treatment operations.

How did system integrator Next Control overcome the geographical challenges, locked hardware platforms, and software licensing costs to make it happen?

Read More

Topics:

Case studies,

Water & wastewater,

groov EPIC,

groov RIO,

SCADA

New case study shows how you can connect numerous remote sites into a single monitoring system.

Monitoring a solar power plant is no small task, but it’s easier when everything is in one place and under your control.

Now imagine monitoring 30 plants, built by various contractors, scattered across 3,000 kilometers (1,864 miles) of remote terrain, and using a patchwork of inconsistent control systems. Does this scenario sound familiar?

In a new case study, find out how Interlog, an IoT-Certified OptoPartner, was able to design and implement a consistent solution.

Read More

Topics:

Energy management,

Case studies,

groov EPIC,

energy monitoring