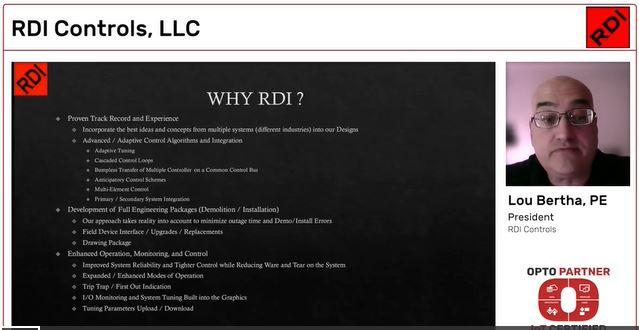

Experienced S.I. harnesses the power of Opto 22’s control system.

One thing is for sure -- RDI Controls knows turbine and governor control systems. That said, if you are looking for an experienced Opto 22 systems integrator that can tackle most any application, have a look at our latest OptoPartner video.

Read More

Topics:

PLCs,

PAC Control,

PID loop control,

groov EPIC,

industrial automation,

snap pac,

OptoPartner,

OptoPartner video

Listen in as Opto 22's Josh Eastburn and Benson Hougland discuss edge computing concepts with Automation World's Dave Greenfield.

Automation World continues its informative podcast series "Get Your Questions Answered" with an all new podcast for 2020. This podcast series connects with industry experts to answer the questions of automation tech users across the process and discrete manufacturing industries.

Read More

Topics:

PLCs,

IIoT,

groov EPIC,

Automation World,

podcast,

edge computing

Opto 22's groov EPIC® system starts shipping on May 18.

You can start ordering now!

Pre-orders will ship first, and based on early feedback from several EPIC Roadshows, this new system will be in high demand. Customers are excited about the built-in features of groov EPIC, not only for IIoT applications but for all automation and data acquisition applications.

Here are just a few of these features:

Read More

Topics:

Process control,

Discrete control,

groov,

Internet of Things,

PLCs,

Remote monitoring,

IoT,

Machine builder,

New products,

Integrators,

I/O,

PAC Control,

IIoT,

Industrial Internet of Things,

Node-RED,

Data acquisition,

MQTT,

Ignition Edge,

EPIC

You've been asking for more details about our brand-new groov EPIC® system for the IIoT and automation, and here they are!

We just published a part numbers list and the first several data sheets, with preliminary descriptions, specs, wiring diagrams, and dimensions. So take a look and start planning the system you want.

Read More

Topics:

Process control,

Discrete control,

groov,

Internet of Things,

PLCs,

Remote monitoring,

IoT,

Machine builder,

PACs,

OEM,

New products,

Integrators,

I/O,

IIoT,

Industrial Internet of Things,

Data acquisition,

EPIC

When we announce a new product, we want you—our loyal customers and OptoBlog readers—to be the first to hear about it.

And this isn't just one product. This is EPIC: the world's first Edge Programmable Industrial Control system—a brand-new I/O and control system built for the future of automation and designed for the way you work.

Read More

Topics:

Energy management,

Process control,

Food & beverage,

Discrete control,

groov,

Internet of Things,

PLCs,

Remote monitoring,

Water & wastewater,

IoT,

Machine builder,

PACs,

OEM,

New products,

Integrators,

I/O,

PAC Project,

Building management,

Oil & gas,

PAC Control,

IIoT,

Industrial Internet of Things,

Node-RED,

Data acquisition,

MQTT,

Ignition Edge,

EPIC

In a recent developer survey conducted by the Eclipse IoT Working Group, IEEE IoT, and Agile IoT, 40.8% of respondents indicated that the IoT solutions they were either currently building or planning to build are IoT platforms or IoT middleware.

Almost every large IT or OT company today has some form of IoT platform or middleware.

In fact, right now there are over 150 self-described IoT platforms in the market today. Not neccessarily created equally.

Read More

Topics:

Energy management,

PLCs,

IoT,

PACs,

REST,

IIoT,

Node-RED

Note that the information below applies not only to PCs, PACs, and PLCs, but to pretty much any industry-standard compliant network device.

There are a ton of great network analysis tools out there today that you can pay huge sums of money for. But a go-to industry standard, and my tool of choice for everyday network troubleshooting, is a free piece of software called Wireshark.

Read More

Topics:

PLCs,

IoT,

PACs,

Networking,

IIoT

Process Control

Process control systems are used in everything from advanced manufacturing to run-of-the-mill activities at home, like heating your house and brewing your beer. (You do brew your own beer, don't you?)

A control system that manufactures a product requires monitoring and control of many different process variables, while some at home require little more than a timer. For example, in manufacturing we may use flow meters to make sure fluids flow through pipes at a certain rate, or float meters to ensure ingredients fill a vat to a specified level.

When I brew beer at home, I may use a temperature sensor in my mash tun, wired to a controller that’s controlling my heating element to keep the mash tun at just the right temperature for optimum starch-to-sugar conversion. This is an example of a closed-loop control system.

(To see how small closed-loop control principles are scaled up to build industrial process control applications, check out the New Belgium Brewery case study and see how they use Opto 22 gear to brew their world-famous Fat Tire and other beers.)

Read More

Topics:

Food & beverage,

PLCs,

Tips,

PACs,

Oil & gas

You never feel like you know enough about security.

And security issues and recommendations are constantly changing, as the bad guys try to hack in and the good guys try to keep them out.

Here are a couple of new blog posts on this important subject, both by Opto 22's Matt Newton, who has years of experience in both automation and IT (information technology).

Read More

Topics:

Internet of Things,

PLCs,

IoT,

optonews,

PACs,

Security,

IIoT,

Industrial Internet of Things,

OptoNews 2017-01-18

Sinking or Sourcing?

Let’s take a quick look at the topic of sinking and sourcing outputs.

Where did the difference come from, and where does it matter in automation?

Quick answer: you often have to choose the correct module because the device you are wiring requires either a sink or source. For example, if you have a prebuilt electrical cabinet, it may be wired using a common positive or a common negative method. Thus you HAVE to choose the correct digital output module for the way the panel is wired.

Read More

Topics:

PLCs,

Electronics,

Tips,

IoT,

Machine builder,

OEM,

I/O