New case study shows how to overcome the limitations of closed, vendor-specific control systems.

Are your building automation systems ready to stand up to harsh industrial environments or unexpected power outages?

When variables like temperature or airflow are crucial, you can't afford any downtime.

That was the problem at Pearl Pharma™, a cannabis cultivator in California, whose brand-new facility didn’t work the way it was supposed to.

See how they overcame their application challenges.

Read More

Topics:

Case studies,

groov EPIC,

groov RIO

New case study explains how edge technology can help you achieve advanced data acquisition systems with real-time visibility.

If you've ever tried to manage remote operations with many service providers working in siloed systems, you understand the challenge of getting accurate data.

With a heavy reliance on manual processes, like spreadsheets and equipment with no internet connectivity, it can be a struggle to prove performance and defend business decisions.

Facing these types of challenges, Pennsylvania-based Deep Well Services (DWS) knew they needed an advanced data acquisition (DAQ) system that could survive the realities of field work. But how to do it?

Read More

Topics:

Case studies,

Oil & gas,

groov EPIC,

data visualization,

digital transformation

New Control Global article shows you how to automate process data collection and monitoring in highly isolated locations.

Have you ever thought it would be possible to move data from the Amazon jungle to the cloud?

You can see a real working example of how it was achieved with Ignition Edge software, groov RIO hardware, and Azure Cloud. Get all the details in Jim Montague's recent article in Control Global.

Read More

Topics:

Case studies,

Ignition Edge,

OptoPartner,

groov RIO,

SCADA

Ridge Vineyards explains how to go from manual system checks to new automated control systems that integrate seamlessly with existing equipment.

Are maintenance issues disrupting your day-to-day operations? Are manual "old school" systems causing unplanned shutdowns?

It's a common scenario in many industries, but Opto 22's new case study involves an agricultural application that needed an automated, scalable, reliable solution.

Learn how Ridge Vineyards gave its operators real-time control and remote monitoring of its wastewater processes.

Read More

Topics:

Case studies,

groov View,

groov EPIC

New case study demonstrates how you can overcome outdated reporting systems and the challenge of getting live data from legacy equipment.

Are manual processes and human errors limiting your visibility and insights into your production performance? Are you dealing with a variety of machines with different control hardware for each?

Moriroku® Technology North America (MTNA) was facing all those challenges and decided it was time for a digital transformation initiative to enhance resilience, efficiency, and competitiveness.

See what they learned along the way, and how their "start small" philosophy resulted in huge gains.

Read More

Topics:

Case studies,

Ignition,

groov RIO,

digital transformation,

smart manufacturing

Are your systems able to withstand severe weather threats or power failures? Learn how a nationwide bank restored critical cooling without infrastructure changes.

Have your industrial control systems been put to the test? Do you have monitoring and control mechanisms in place to face a natural disaster?

After an HVAC retrofit in 2022, the headquarters of a nationwide bank in Australia encountered an unplanned shutdown of their data center, which was critical to their banking operations. Learn how they quickly bounced back, despite facing strict regulations, time constraints, and a list of new required system features.

Read More

Topics:

Case studies,

groov EPIC,

system integrator,

groov rio emu,

data center

See why groov RIO edge I/O with Ignition Edge has become a key component to college Industry 4.0 labs and preparing students for real-world applications.

Have you wondered what a modern day college engineering lab is equipped with for today's students? What's the latest technology that's needed to prepare students for careers in industrial automation? Is it the same technology you're researching for your projects?

Inductive Automation explores the classroom in their latest case study featuring Clovis Community College. You'll learn why Ignition software pairs well with Opto 22 groov devices to meet the challenges of today's IIoT applications, as well as exceeding educational expectations.

Read More

Topics:

Case studies,

IIoT,

industrial automation,

groov RIO,

Inductive Automation

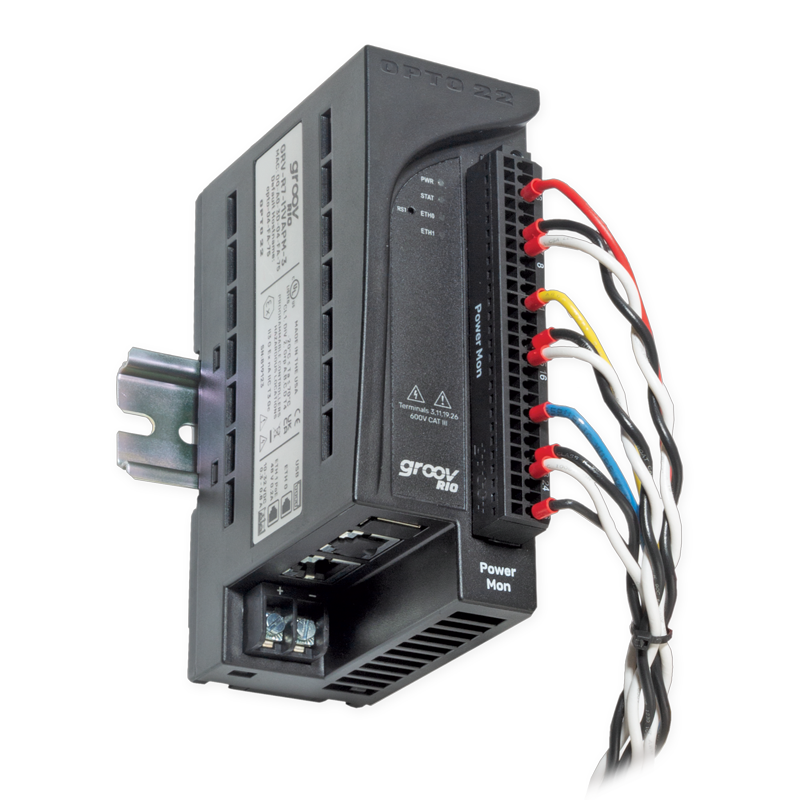

See how Schulman Engineering addressed their energy usage, analyzed costs, and established preventive maintenance with the groov RIO energy monitoring unit.

Are you working on machine health initiatives and predictive maintenance? Do you want to track (and reduce) operating costs? Energy management can be the key to achieving these goals.

Schulman Engineering, an industrial automation and system integration company located in Southern California, recently shared a client success story using Opto 22's groov RIO EMU (GRV-R7-I1VAPM-3).

Is it possible to find a secure solution that translates energy data into usable information for cost management, process improvement, and equipment reliability?

Read More

Topics:

Energy management,

Case studies,

system integrator,

groov rio emu,

energy monitoring

Learn from this new case study as CryoPhit USA explains how they overcame the complexity of cryotherapy systems with an advanced automated solution.

CryoPhit USA needed to design a system that was easy to use, maintain, and service, ensuring accessibility for end users, operators, and refrigeration technicians. This meant access to real-time data would be key. Sound familiar?

In this case study, find out how the groov RIO provided real-time data, predictive diagnostics, and remote access for their innovative cryochambers.

Read More

Topics:

Case studies,

OEM,

groov RIO

Is your SCADA system holding you back? See how the Wheeler Ridge-Maricopa Water Storage District fixed their outdated systems.

If you’re managing critical infrastructure, how much do you trust your SCADA system? Are you getting real-time, reliable data, or are you constantly battling delays, communication failures, and rising maintenance costs?

Wheeler Ridge-Maricopa Water Storage District faced those same challenges—until they partnered with Avadine, an IoT-certified OptoPartner, to upgrade their SCADA system. Read about their new solution and how they got there.

Read More

Topics:

Case studies,

groov EPIC,

Ignition,

OptoPartner