New case study shows how StrataVu and groov EPIC secure a flexible future for Oil & Gas production.

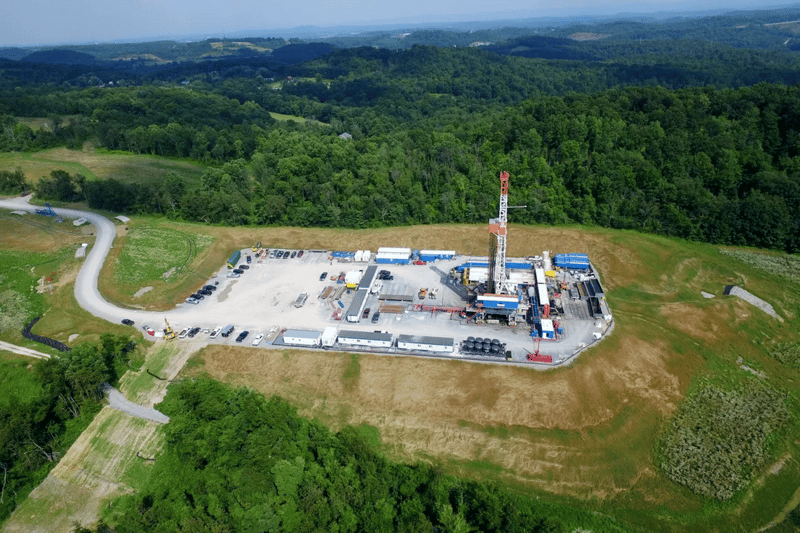

When the hardware for the automation system you’ve deployed throughout your entire installed base is suddenly declared end-of-life, you’re faced with a problem. That’s what happened to Apex Energy LLC, a natural gas exploration and production company, headquartered just outside Pittsburgh, Pennsylvania.

As a longtime customer of systems integrator and Opto technology partner Strata Innovative Solutions, Apex had used Strata’s field-proven PadPro automation solution starting with their second drilling site, or well pad. They were happy with the solution. But in 2019-2020, manufacturers of the hardware components began to end-of-life their products. For their planned growth, Apex needed a new solution that would offer as seamless a transition as possible.

This solution is the subject of Opto 22's latest case study, which covers:

- Why groov EPIC proved to be the ideal controller for this oil and gas application

- How StrataVu software was created to work with groov hardware

- The distributed architecture system Apex uses for easier expandability

- Other software programs included in groov EPIC that helped to achieve the complete solution package

You can read the complete case study on our website or download your own PDF copy.

Interested in seeing how groov EPIC or groov RIO products are being used in other industries and applications world-wide? Visit the groov Case Studies Library.