New factory saves initial and recurring costs, improves products with groov EPIC and Ignition.

Moving to Industry 4.0 takes time and determination, especially for an established company in a heavy industry. Castings Foundry POK in Guadalajara, Mexico, a Nucor subsidiary, uses equipment from manufacturers all over the world, which may include PLCs from a variety of automation suppliers. But data from all this equipment needed to be shared with corporate SCADA and ERP systems.

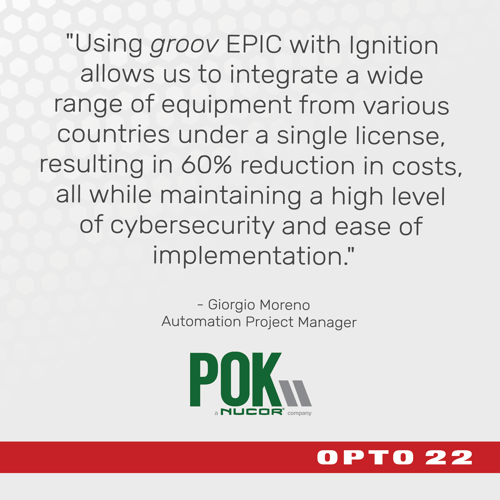

In this new Opto 22 case study, see how POK's new factory solved this problem, saving an estimated 60% in initial costs, making operators' jobs easier with comprehensive HMIs, and improving product quality.

The case study discusses:

- How long-standing customer relations can lead to new custom designs with Industry 4.0 technology

- How POK aggregates all process information from equipment and PLCs and then exchanges that information with corporate SCADA and ERP systems

- Why the groov EPIC and its direct integration with Inductive Automation’s Ignition SCADA software is a game changer

- What advantages come with using 2 operator interfaces (HMIs), both Ignition Perspective and the groov View software built into groov EPIC

- What types of cost savings are the direct result of the new IIoT systems

You can read the complete case study on our website or download your own PDF copy.