Learn more about automation products and IIoT technologies through the Interactive Demo section on the website.

Many people benefit from hands-on learning, which is why we've always maintained a section of interactive resources on the Opto 22 website. If you haven't tried it yourself, take a few minutes to point, click, and discover some new product features and functions.

These website demos cover advanced edge computing and IIoT concepts using groov EPIC and RIO products, building custom HMIs with groov View, and even basic automation 101 concepts like PID turning.

Here are some website demos you can explore.

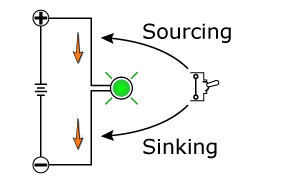

Click through each of the steps in this online demo to see how groov EPIC and groov RIO's security and connectivity options interact to build bulletproof infrastructure. Each step adds illustrations and descriptive text to guide you through the build.

The result is a complete system overview of a multi-vendor network and software integration. It illustrates how to:

- Secure legacy PLCs and acquire their data without disturbing existing systems

- Remotely access field devices through secure, on-demand VPN conduits

- Securely share data with SCADA systems and MQTT applications

- Scale out your infrastructure using groov RIO edge I/O

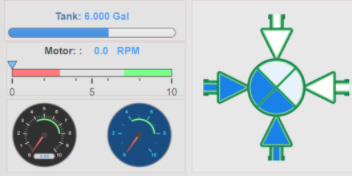

With browser-based groov View, you can easily build a web-based, responsive operator interface to see and interact with exactly what you need. groov View is included with groov EPIC and also available separately for Windows-based PCs (groov Server for Windows). To take a deeper dive into what you can do with it, check out the groov View Primer.

The demo shows:

- User interface examples

- Built-in gadget library available for your designs

- Custom graphic options

- Animated indicator gadget options

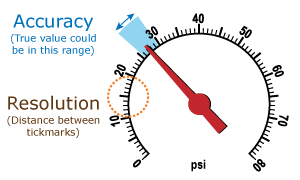

Some applications require highly accurate values or very fine resolution, while others do not. Choosing the right I/O module for your application will save you time and money.

So here's a hands-on demo for you to really see how accuracy and resolution work.

You can review the definitions, see what happens when an analog value is morphed into a digital value for computers to use, and check out the example of a temperature probe.

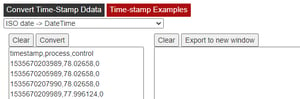

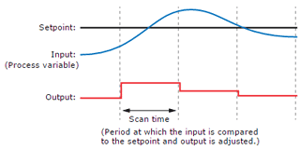

In automation, proportional integral derivative (PID) control loops are common, useful, and tricky to get right. Each loop is different and each requires individual tuning for maximum effectiveness.

This demonstration guides you in applying the Ziegler-Nichols Reaction Curve, or Open-Loop tuning, method of estimating PID tuning parameters.

Plug in data for your PID and the tuner calculates P, I, and D values for tuning, plus a suggested scan rate.

These are just a few of the demos to choose from. Don't stop there. Check out our complete list of interactive demos, and we hope you continue on your learning path!