Hear from OptoPartner 4IR Solutions in this guest blog post about the ideal device for running Ignition Edge software.

The Ignition platform by Inductive Automation provides a modern, robust, and flexible development environment for building SCADA, IIoT, and Industry 4.0 applications in support of digital transformation initiatives.

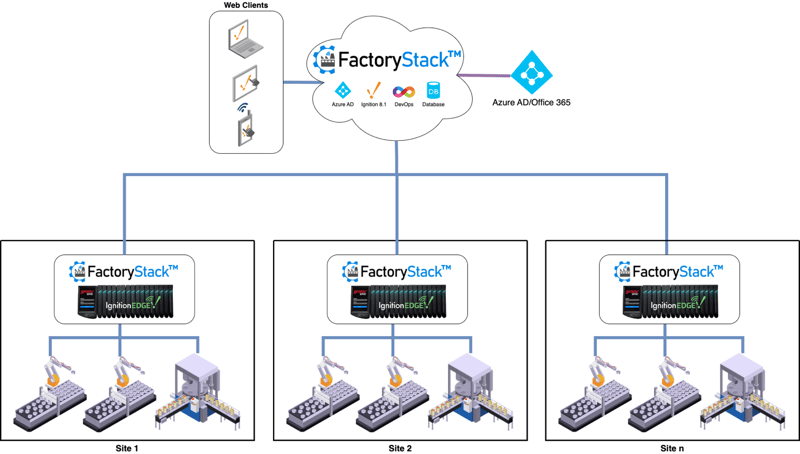

Ignition's scalable architecture makes it a perfect solution for building both fully on-premises applications as well as "hybrid cloud" applications that are distributed across both the cloud and the edge. In the industrial automation world, most cloud-enabled solutions still require an on-premises component to allow control of equipment and data buffering in the event of connectivity issues. Ignition provides a purpose-built Ignition Edge product suite for this use case, which must be deployed on a complementary hardware platform that is appropriate for running plant-floor applications.

Let's consider for a moment what an ideal device for running Ignition Edge might look like—our hypothetical Ignition Edge "Dream Machine."

Powerful, Secure Industrial PC

Ignition Edge can technically run on a low-powered Raspberry Pi, but non-trivial applications require greater resources. For manufacturing applications, our Dream Machine should have enough CPU, RAM, and storage to run real-world workloads and be able to buffer data in the event of lost connectivity to the Internet. Critically, our Dream Machine must provide robust security features to reduce the risk of security incidents, such as unauthorized access and ransomware attacks.

Industrial-Grade PLC

Our Dream Machine needs to feel at home in rugged environments and to support a wide variety of I/O connectivity options, avoiding the need to have a separate PLC to interface with these devices. Smart sensors with built-in support for protocols like MQTT are becoming more common, but analog and digital I/O are still key to interfacing with most control devices.

Affordable (and Available)

Our Dream Machine needs to be affordable enough to justify typical data collection use cases. Importantly, with the ongoing supply chain shortages, it's equally important that the hardware is readily available and remains affordable (unlike, say, a Raspberry Pi).

Practical Licensing Model

Licensing costs for Windows and proprietary programming software can get expensive. Our Dream Machine should be built on best-in-class open source technologies to minimize unnecessary costs and provide greater flexibility.

Secure Remote Access

Edge devices are often installed in remote or hard-to-access places. Having to plug into the physical device for programming or troubleshooting can quickly become a burden. Our Dream Machine should support secure remote access that allows for remote upgrades, monitoring, and troubleshooting.

From a Dream to Reality

At 4IR Solutions, we needed to find this exact "Dream Machine" to serve as the edge component of our fully managed hybrid cloud infrastructure products, FactoryStack™ and PharmaStack™. Since our products are built around Ignition and Ignition Edge (and soon, Ignition Cloud Edition), we looked to Inductive Automation's Ignition Onboard program, and ultimately decided on the groov EPIC.

We were delighted to discover that the EPIC met or exceeded our expectations for all of the above criteria.

Powerful, Secure Industrial PC

The EPIC's PR2 processor provides a sizable RAM and storage boost over its predecessor, making it capable of running the latest (8.1) version of Ignition Edge or even full-blown Ignition. Our customers use Ignition Edge Sync Services running on the EPIC to store and forward locally collected data and to provide fallback control to local SCADA clients in the event that connectivity to the cloud is lost. From a security standpoint, the EPIC reflects smart design decisions (such as baking Ignition into the firmware), provides sane defaults (such as making SSH access opt-in), and comes with detailed guidance for maintaining a strong security posture.

Industrial-Grade PLC

Unique among Ignition Onboard products, the groov EPIC is a real and fully expandable PLC, capable of connecting to field I/O while withstanding harsh temperature and humidity conditions. The EPIC can be installed in field cabinets on standard DIN rail and has a front-facing information display so users can diagnose simple issues or control applications. Some of our customers are replacing their legacy Environmental Monitoring Systems, requiring both PCs and PLCs, with a single EPIC.

Affordable (and Available)

By acting as both an industrial PC and PLC in one, the EPIC provides a great value for the price point. Like all Opto 22 products, the EPIC is designed, manufactured, and supported in the USA, which reduces the impact of long lead times and shipping delays. This has enabled our customers to accelerate their cloud adoption journeys.

Practical Licensing Model

The EPIC runs an embedded Linux operating system rather than Windows. PLC programming in any IEC 61131-3 compliant language can be performed with the freely available CODESYS Development System or in Opto 22's own PAC Project Automation Software Suite (available in both free and paid options). Also, the EPIC bundles the open-source Node-RED application, a popular low-code toolset for building applications. The low cost allows us to lease EPICs as part of our managed services at a competitive price point.

Secure Remote Access

The EPIC includes an onboard OpenVPN client, which we can use to establish a secure, encrypted tunnel between the device and dedicated customer infrastructure in the cloud. We use this tunnel to securely monitor and perform management tasks, including patches, upgrades, and backups.

In conclusion...

The Opto 22 groov EPIC truly provides a best-in-class device for edge and hybrid cloud solutions powered by Ignition. It strikes the right balance of performance, features, security, and cost to provide a solid foundation for many types of manufacturing workloads.

Historically, even the best on-premises computing hardware at manufacturing sites tends to get neglected. These Operational Technology—or "OT"—systems tend to fall out of the purview of IT teams, and with machine uptime being a top priority, patches and updates are applied infrequently, if at all. Operations teams are instead focused on keeping the plant running rather than managing, monitoring, and backing up their computing platforms.

As an OptoPartner, we at 4IR Solutions have standardized on the groov EPIC as the edge component of our hybrid cloud products FactoryStack™ and PharmaStack™. If you’re tired of managing (or ignoring) your OT infrastructure and would rather focus on building value-creating applications that can take advantage of the cloud using tools like Ignition, drop us a note or schedule a call with one of our experts today.