Hear from John Harrington, Co-Founder and Chief Product Officer at HighByte, as our guest series on the open automation ecosystem continues.

Many companies are looking to improve their business by collecting and making better use of industrial data. Whether you are performing AI/ML-based predictive analytics, setting up quality dashboards, measuring lean projects, or simply logging for traceability, you require consistent, reliable, and secure data. At HighByte, an industrial software company, we’re focused on providing the infrastructure to reliably manage data delivery at scale.

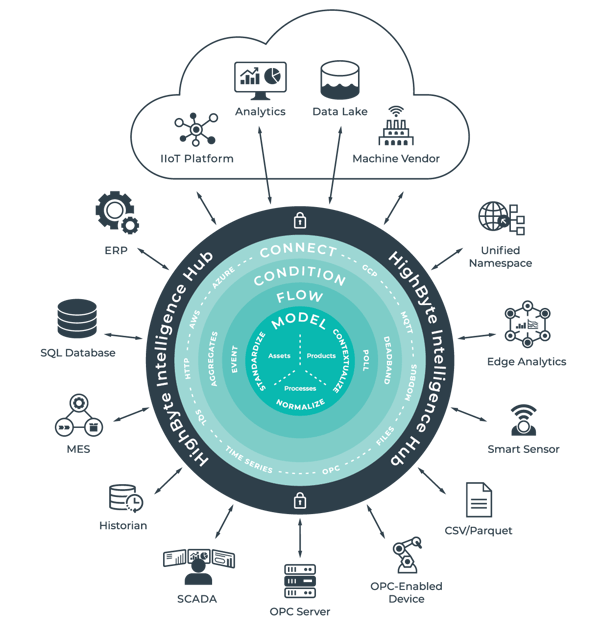

HighByte Intelligence Hub provides industrial companies with an off-the shelf solution to accelerate and scale the use of operational data throughout the enterprise by contextualizing, standardizing, and securing this valuable information. Think of HighByte Intelligence Hub as the data network, managing and maintaining your data pipelines.

The Intelligence Hub can run at the edge on Opto 22’s groov RIO and groov EPIC lines of industrial edge gateways and edge programmable industrial controllers. There the software collects, conditions, merges, and models real-time, transactional, and time-series data into a single payload, and then delivers contextualized, correlated information to all the applications that require it—from edge to cloud. Using the Intelligence Hub, you can manage data flows, react to changes or issues with connected systems, and provide robust and reliable data to consuming applications. Using multi-hub configuration, you can distribute multiple hubs across your site, field, or enterprise while centrally controlling and governing the data.

The Intelligence Hub can run at the edge on Opto 22’s groov RIO and groov EPIC lines of industrial edge gateways and edge programmable industrial controllers. There the software collects, conditions, merges, and models real-time, transactional, and time-series data into a single payload, and then delivers contextualized, correlated information to all the applications that require it—from edge to cloud. Using the Intelligence Hub, you can manage data flows, react to changes or issues with connected systems, and provide robust and reliable data to consuming applications. Using multi-hub configuration, you can distribute multiple hubs across your site, field, or enterprise while centrally controlling and governing the data.

With the Intelligence Hub, users can speed system integration time, rapidly leverage contextualized data for analytics, AI, and ML applications, and govern data standards across the enterprise. Let’s take a look at some of the ways HighByte Intelligence Hub is being used in the real world to achieve these outcomes.

With the Intelligence Hub, users can speed system integration time, rapidly leverage contextualized data for analytics, AI, and ML applications, and govern data standards across the enterprise. Let’s take a look at some of the ways HighByte Intelligence Hub is being used in the real world to achieve these outcomes.

Paper Manufacturer: Predictive Asset Maintenance

In the paper making process, keeping the line running smoothly is critical to delivering high quality paper and tissue paper products. A critical component to the line’s operations are the many motors that drive the equipment. Monitoring these motors to predict failure and proactively notify the maintenance team increases production, reduces scrap, and reduces emergency maintenance costs.

In this use case, the paper manufacturer was using the cloud to store and perform predictive asset maintenance calculations on the data. These analytics required very high resolution: 1- millisecond data in 1-second bursts (1000 records), every 10 minutes. HighByte Intelligence Hub was used to collect data from the motors, transform and contextualize the data, and then send it to the cloud platform for analytics. The Intelligence Hub provided a low-code interface to easily synchronize the high-frequency data and publish clean, standardized data models directly to multiple services in the cloud platform. This significantly reduced the amount of custom code required to deliver the predictive asset maintenance solution.

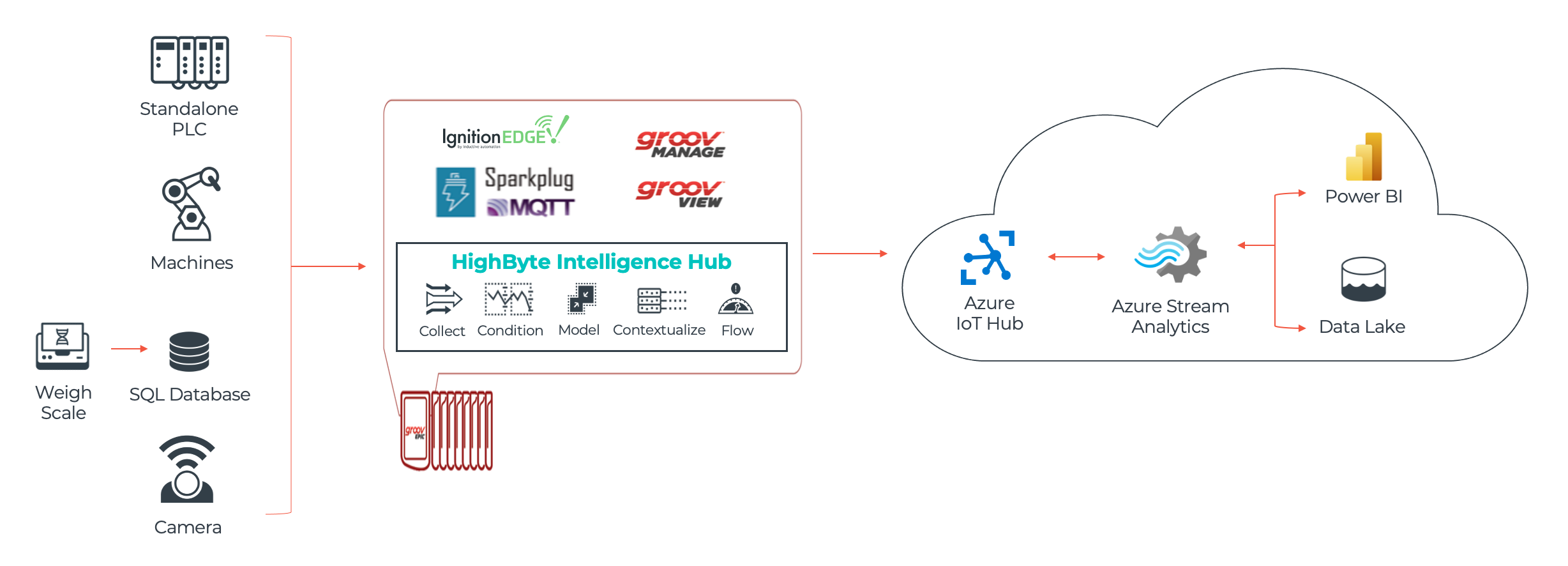

Automotive supplier: First Pass Yield

An automotive supplier needed a way to integrate disparate data streams—from OPC UA servers, the test sand at the end of the line, and a SQL database—into a single data set, to build Power BI dashboards in Microsoft Azure with the goal of providing real-time information to their quality staff. Previous methods meant that data processing took days and weeks. As a result, quality events were never acted on in a timely manner, resulting in lower first-pass yields across multiple product lines. Manually collecting and curating the data from different data sources was the primary barrier to unlocking their industrial data’s value. Doing it for each line was prohibitively resource intensive.

The manufacturer turned to the Intelligence Hub to create a contextualized data set that could seamlessly feed dashboards with real-time data. The Intelligence Hub collected real-time data directly from OPC, SQL, CSV files, and MES sources, and produced a standardized data payload across all lines to feed Power BI dashboards in Azure. This data framework eliminated the manual effort required to curate the production data, allowed the team to react quickly and easily to changes in the source data or new dashboard needs, and allowed the manufacturer to improve their process in real time—improving their first-pass yield.

Pharmaceutical CDMO: Traceability

A pharmaceutical contract development and manufacturing company (CDMO) wanted to track their drug production data and deliver comprehensive, real-time reporting to their clients as the product moved from bioreactor to delivery. They also wanted to reduce the amount of time required to identify the root cause of quality failures. Creating a holistic digital batch report was extremely resource intensive with data in many systems and structures across many departments.

This pharmaceutical CDMO turned to the Intelligence Hub to automatically create a comprehensive batch report model to drive their client reporting and greatly speed the process of identifying root causes of quality failures. They were able to define exactly the data model that satisfied their business requirements, using the Intelligence Hub to connect to the disparate data sources and publish the complete batch report for internal and external use.

The batch report data model defined in the Intelligence Hub was used to stitch disparate data sources into a simplified, complete view of the product environment. It was used to catch quality issues early in batch processes, resulting in multimillion-dollar savings.

Conclusion

HighByte Intelligence Hub is a data integration solution designed for industrial data and for the Operational Technology (OT) team to configure and maintain. It is a no-code solution to integrate OT and IT systems. It is the foundational solution for building a unified namespace (UNS) across the enterprise. The UNS is a consolidated, abstracted structure by which all business applications are able to consume real-time industrial data in a consistent manner. There are several architectural choices for implementing a UNS, and the Intelligence Hub can play a key role in each approach by both providing access and structure to the UNS or acting as the UNS.

Customers have found the Intelligence Hub enables them to:

- Scale their digital and analytics programs faster

- Reduce or eliminate custom code required to integrate systems, reducing the IT maintenance burden

- Allocate cloud spend across more successful projects

- Improve data curation and preparation time for AI and ML applications, enabling data analysts and data scientists to focus on identifying business value

- Improve agility of OT and IT systems and processes

HighByte provides a single solution to manage, automate, and maintain data pipelines. This results in easy, scalable, and maintainable data when and where you need it. This is the art of the possible!

--John Harrington

Co-Founder & Chief Product Officer, HighByte

John Harrington is the Chief Product Officer of HighByte, focused on product management, customer and partner success, and company strategy. His areas of responsibility include market research, customer use cases, product priorities, go-to-market, and financial planning.

John Harrington is the Chief Product Officer of HighByte, focused on product management, customer and partner success, and company strategy. His areas of responsibility include market research, customer use cases, product priorities, go-to-market, and financial planning.

John is passionate about delivering technology that improves productivity and safety in manufacturing and industrial environments. He has spent his 25-year career both delivering software to manufacturers and working for manufacturers in operations roles. This experience has given him a unique perspective on how suppliers and end users each play an integral role in implementing new technology solutions.

John has a Master of Business Administration from Babson College and a Bachelor of Science in Mechanical Engineering from Worcester Polytechnic Institute.