Intrinsics Imaging’s AI-powered vision system uses groov RIO to connect the cloud to the edge.

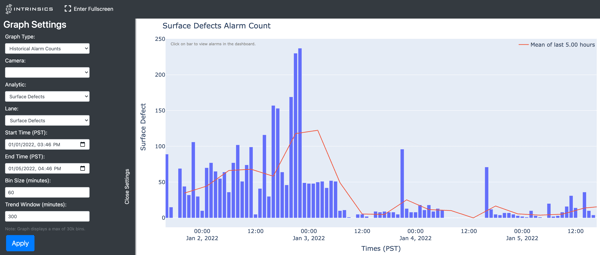

Machine vision systems can recognize superficial aberrations in manufactured goods—like lines, spots, holes, color discrepancies, and more—that would typically require time-consuming manual inspection. California-based Intrinsics Imaging solves this problem with its Heijunka Vision analytics-as-a-service software. But when Intrinsics was approached by a customer hoping to integrate Heijunka directly into process controls, it looked to Opto 22’s groov RIO edge I/O for a way to connect the cloud to the edge.

Typically, Heijunka integrates with SCADA systems to create analytics dashboards, alarms, and quality control actions, so connecting directly to the physical process was a new challenge. “This was surprisingly difficult to figure out,” says Eric Cheng, CTO at Intrinsics. “I wasn’t sure what kind of device could provide a physical interface to our cloud-based system and also satisfy our technical and operating requirements.”

Typically, Heijunka integrates with SCADA systems to create analytics dashboards, alarms, and quality control actions, so connecting directly to the physical process was a new challenge. “This was surprisingly difficult to figure out,” says Eric Cheng, CTO at Intrinsics. “I wasn’t sure what kind of device could provide a physical interface to our cloud-based system and also satisfy our technical and operating requirements.”

A new Opto 22 case study outlines how Intrinsics implemented this edge architecture to meet the challenge.

Learn:

- Why a communication infrastructure built on MQTT was essential

- How cybersecurity was implemented to allow for safe communication over the internet

- How much process time and cost was saved using groov RIO's built-in software tools