Josh Eastburn

After 12 years as an automation engineer working in the semiconductor, petrochemical, food and beverage, and life sciences industries, Josh Eastburn works with the engineers at Opto 22 to understand the needs of tomorrow's customers.

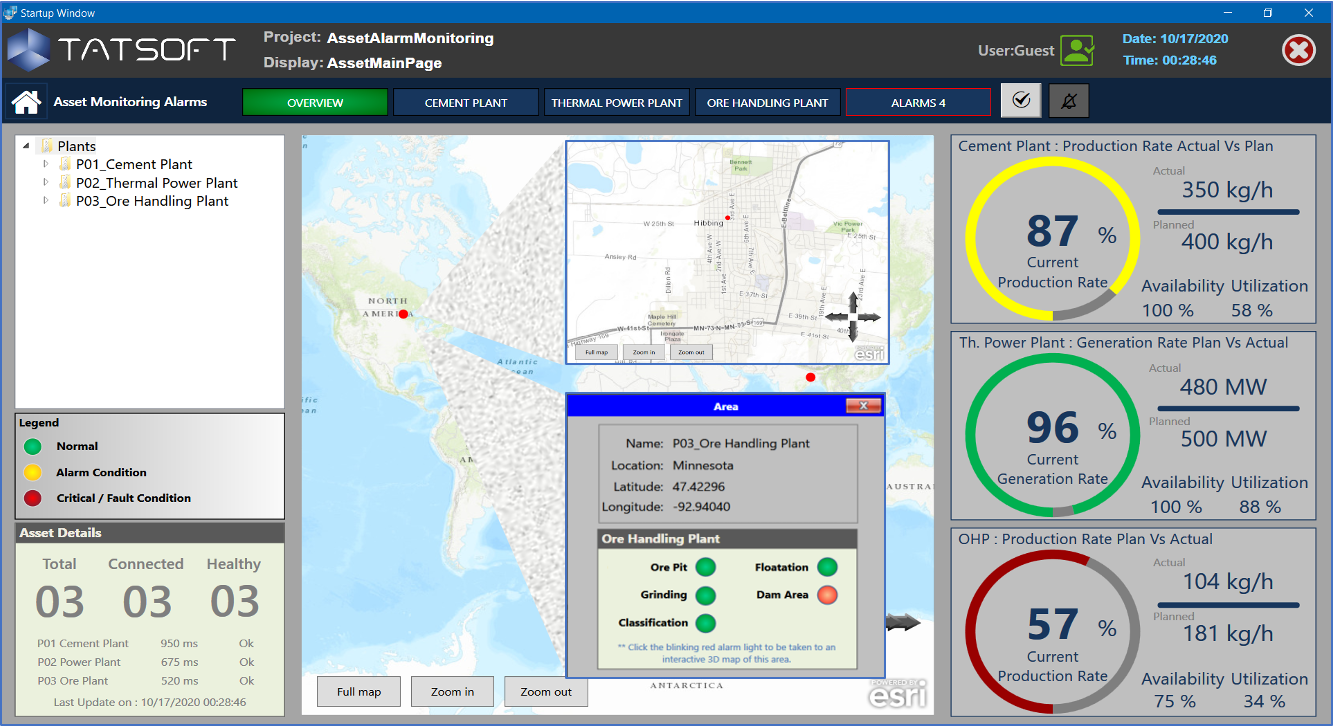

How can you deliver modern Industry 4.0 capabilities that still come in under budget? Harry McCollum of Tatsoft illustrates.

Today’s applications require more than a one-vendor approach. FrameworX by Tatsoft provides an open, extensible software platform as an alternative to the big control vendors. It includes everything you need to build world-class industrial applications at an affordable price: SCADA, HMI, MES, IIoT, mobile, dashboards, and more. With FrameworX, you can do it all without breaking the bank!

Read More

Topics:

groov EPIC,

groov RIO,

Art of the Possible,

open source,

Tatsoft

Want to get started with MQTT today? Ian Skerrett of HiveMQ shows you how, as our guest series on the open automation ecosystem continues.

Many companies are turning to MQTT and Sparkplug to simplify the process of acquiring their industrial data. MQTT provides lightweight, publish/subscribe communication that allows you to decouple hardware from software. By removing these dependencies, you can also remove the data silos that have existed in many industrial deployments. Sparkplug provides a common format for industrial operators to send data that can be processed by different applications. The openness and data interoperability of Sparkplug makes it possible to start implementing many IIoT use cases.

Read More

Topics:

MQTT,

groov EPIC,

groov RIO,

Art of the Possible,

HiveMQ

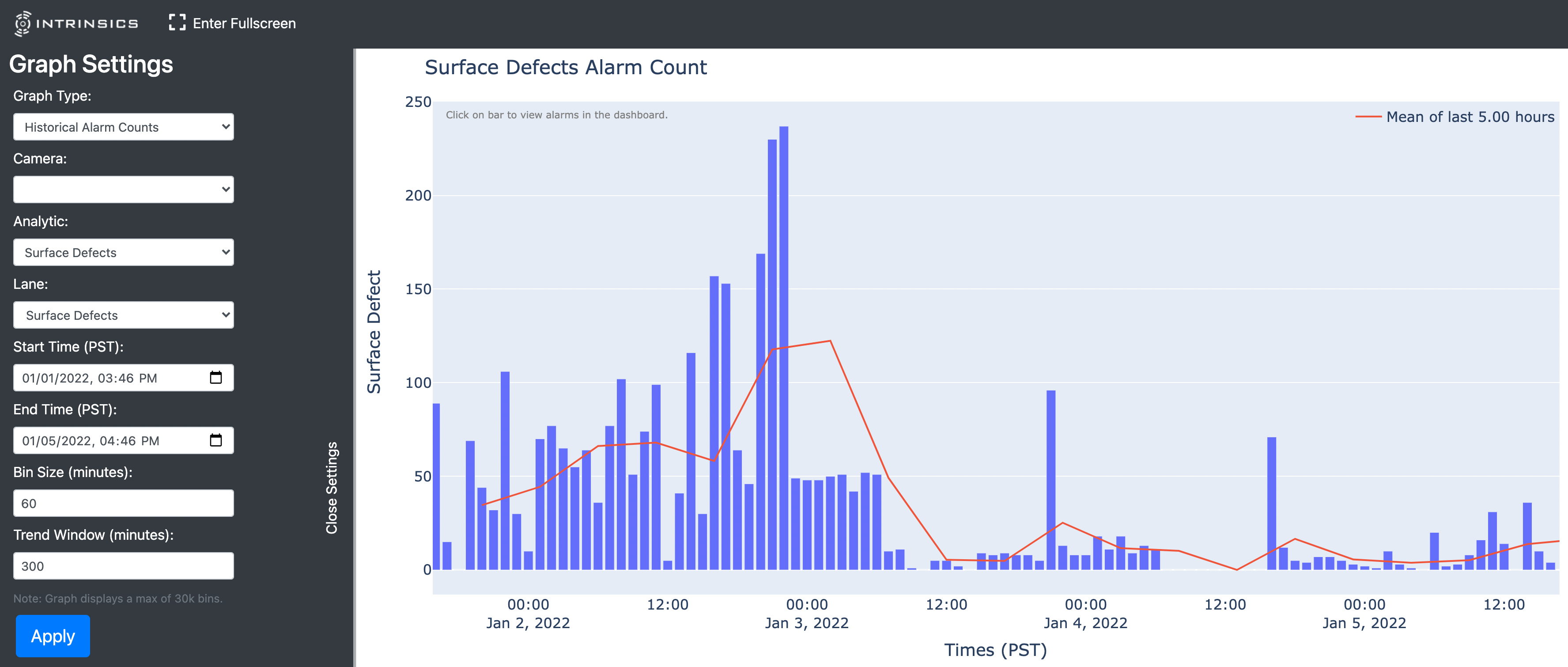

Intrinsics Imaging’s AI-powered vision system uses groov RIO to connect the cloud to the edge.

Machine vision systems can recognize superficial aberrations in manufactured goods—like lines, spots, holes, color discrepancies, and more—that would typically require time-consuming manual inspection. California-based Intrinsics Imaging solves this problem with its Heijunka Vision analytics-as-a-service software. But when Intrinsics was approached by a customer hoping to integrate Heijunka directly into process controls, it looked to Opto 22’s groov RIO edge I/O for a way to connect the cloud to the edge.

Read More

Topics:

Case studies,

Node-RED,

MQTT,

groov RIO,

SCADA

Nathan Field of Ascend Data Tech joins our guest series to explain why and how you should put your process data into a distributed ledger

Blockchain is a revolutionary technology, increasingly ready to change the landscape of business, everything from finance to supply chain. As you set forth into the path of Industry 4.0, you should take stock of how you could integrate blockchain into your own processes. Let's talk about how to know when it could benefit your process and how Opto 22's groov series can help you succeed.

Read More

Topics:

MQTT,

groov RIO,

Art of the Possible,

blockchain

Learn what's possible with MQTT and how you can use it to unlock all the value your OPC systems offer.

Why MQTT?

By now, you've probably heard about MQTT. Since its creation in the late '90s, it's become the most popular protocol for IoT applications, repeatedly touted by organizations like the Eclipse Foundation, big players in cloud services like Microsoft and Amazon Web Services, and influential automation vendors like Inductive Automation.

Read More

Topics:

MQTT,

groov EPIC,

OPC UA

Get everyone on the same page with data tools that help you distinguish the signal from the noise. Tor Eriksen of Clarify explains how.

Clarify helps people turn data into good decisions

Last year, Opto 22 had the opportunity to showcase some amazing partner collaborations like our webcast with HiveMQ and Canary. The open automation ecosystem continues to explode with potential, so this year we wanted to bring you even more.

Throughout 2022, we’ll explore what’s possible when you pair Opto 22 hardware with other open automation tools. This series will include some heavy-hitters you might be familiar with as well as some new names. Hopefully at least one will turn on a lightbulb for you!

Our first guest is Tor-Inge Eriksen of Clarify, a time-series visualization platform that helps users quickly turn data into information. Tor, take it away!

Read More

Topics:

Node-RED,

Data acquisition,

groov EPIC,

machine data,

groov RIO,

system integration,

Art of the Possible,

open source

ICC 2021 Discover Gallery finalist, Perceptive Controls, talks about their continued success with the Waterford, MI Department of Public Works

In February of this year, we looked at a pioneering MQTT Sparkplug project at the Department of Public Works in Waterford Township, Michigan. Thanks to the work of system integrator Perceptive Controls, Waterford’s project went on to become a finalist in the 2021 Ignition Community Conference Discover Gallery and was showcased in the latest Sparkplug Working Group virtual meetup. Recently, I followed up with Kevin Finkler, software engineer at Perceptive, to talk about using MQTT in the real world.

Read More

Topics:

Case studies,

Water & wastewater,

MQTT,

groov EPIC,

Ignition

Sharpen your drawing tools. It's time to go to work.

Visualization for industrial automation is bigger than it’s ever been, and it’s not just about control anymore. As it becomes increasingly important to turn data into information efficiently and ubiquitously, visualization platforms deal with more data types, presentation formats, and a broader range of users and use cases. As always, Opto 22 gives you many tools so you can choose what fits your project best. Let’s take a look at some of those options.

Read More

Topics:

Node-RED,

Ignition Edge,

PAC Display,

groov View,

groov EPIC,

HMI,

Ignition,

groov RIO

Which is right for you?

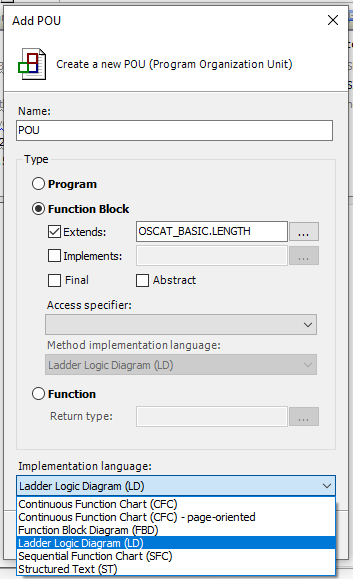

In this series, I’ve been talking about the strengths of CODESYS for control programming on the groov EPIC platform, but it’s not your only option. You can use CODESYS, Opto 22’s flowchart-based PAC Control, or custom applications built using secure shell access (SSH). Whether you’re a CODESYS developer building projects on groov EPIC or still deciding which programming approach to take, it’s worth understanding how and when each tool might be right for you. This post compares CODESYS and PAC Control head to head to help you decide which approach to take for your project.

Read More

Topics:

PAC Control,

CODESYS,

groov EPIC,

CODESYS blog series

Interested in giving CODESYS a try? Here are a few fantastic reasons why you should...

Looking for a solid ladder logic programming environment that doesn’t lock you into a particular vendor? CODESYS provides that and more. With a familiar but powerful set of tools, not only can you use IEC 61131-3 languages like ladder, but you’ll also enjoy code that is open, structured, customizable, and portable.

Read More

Topics:

CODESYS,

groov EPIC,

CODESYS blog series