Nathan Field of Ascend Data Tech joins our guest series to explain why and how you should put your process data into a distributed ledger

Blockchain is a revolutionary technology, increasingly ready to change the landscape of business, everything from finance to supply chain. As you set forth into the path of Industry 4.0, you should take stock of how you could integrate blockchain into your own processes. Let's talk about how to know when it could benefit your process and how Opto 22's groov series can help you succeed.

Do you need blockchain?

In principle, blockchain is Distributed Ledger Technology (DLT), a decentralized database managed by multiple users, shared across even more network participants. It solves many issues involved in data trust, security, and provenance.

But is blockchain right for you? How can you know if it could benefit your process? To answer this, consider these questions:

- If the data I collect is corrupt, do people or businesses suffer?

- Does anyone have incentives to destroy or change the data my business is based upon?

- Does my business depend on others trusting the data?

One sector in which blockchain is already being implemented is supply chain. It's safe to say that an interconnected supply chain, as seen in today's world, answers yes to all three of the questions above. The supply chain touches almost every facet of business, from manufacturing to shipping and logistics, and as many of us are experiencing right now, disruptions to this system can affect organizations across the world.

Many manufacturers are part of a much larger supply chain, in which both they and their customers must trust the data and rely on its accuracy. With the integration of blockchain, all parties involved can be assured the data is accurate and immutable, creating a network in which all parties are acting within the rules defined by the software.

Through the use of smart contracts (software-defined business processes triggered by a given event or set of conditions), contractual business deals can be completed based on new blockchain data. An example could be a product arriving at a factory and a smart contract sending payment to the supplier automatically, without human intervention. This payment would be based on details negotiated before the transaction took place and defined in the smart contract. The contract removes the need for mediators and third parties, drastically reducing the number of disputes that take place.

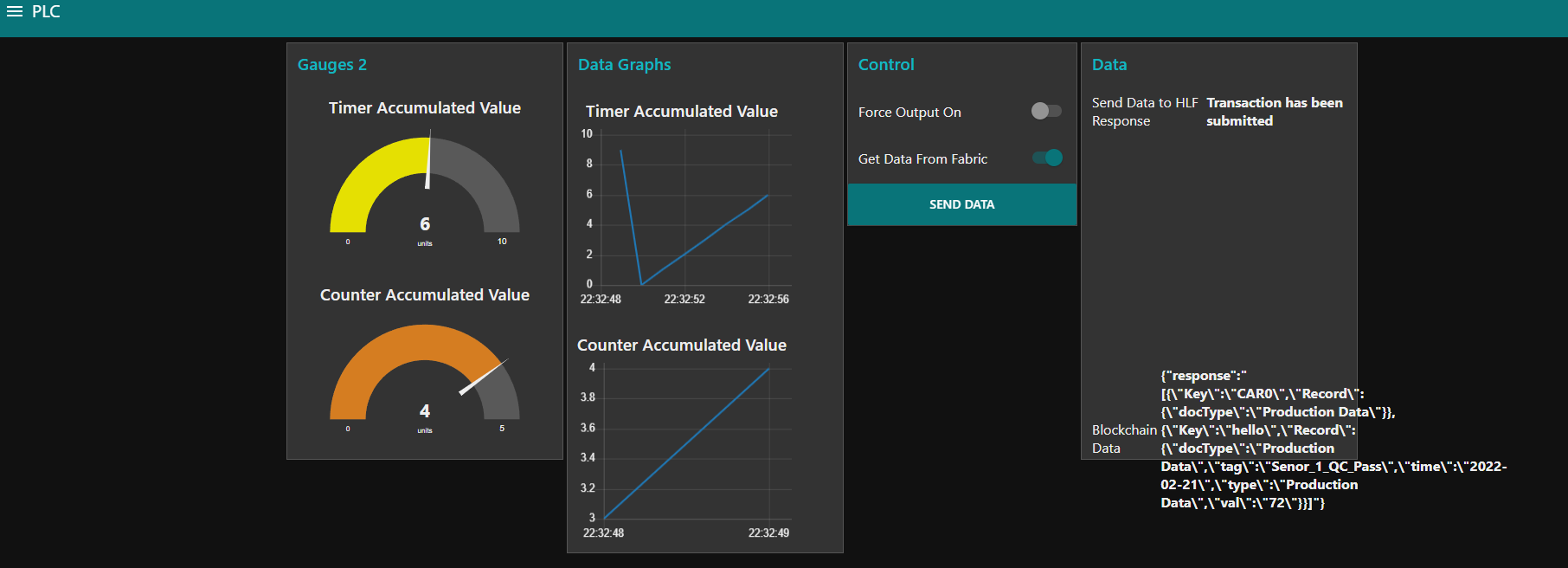

Basic Node-RED dashboard to display, send, and read data from PLC to Hyperledger Fabric (source: Ascend Data Tech)

Basic Node-RED dashboard to display, send, and read data from PLC to Hyperledger Fabric (source: Ascend Data Tech)

Who is already using blockchain?

Although this technology is poised to change many aspects of the industry, let’s focus on a specific sector in which blockchain is already being implemented. This example is interconnected both within the supply chain and manufacturing.

The food manufacturing industry presents a clear opportunity for blockchain, and some early adopters are already realizing its advantages. In a space where there are many regulations, supply chain issues, provenance concerns, and customer distrust, the blockchain can benefit all stakeholders.

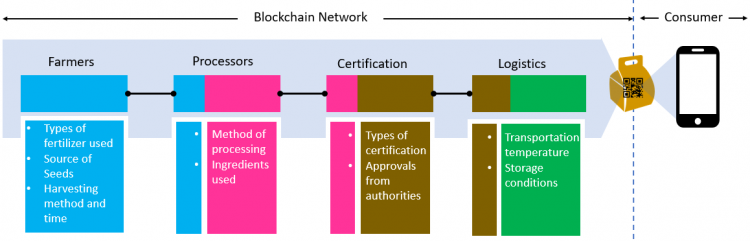

The infographic below shows an example of such a blockchain network. In this example, information is kept in a shared blockchain that contains data about the farmer and their practices, the processor/manufacturer, the certification body, and logistics.

It isn’t hard to see how each block below could represent entire businesses with specific interests in the overall data stored. However, it isn’t until it's all stored on the blockchain that a full picture can be seen, therefore adding real value.

And you are only as good as your weakest link, no pun intended.

As a brief example, imagine how easy it would be to recall an item if all this information was stored and completely trusted across all businesses. The recall process requires tracing contaminated food back to its source, identifying the source of contamination, and coordinating recall of affected foods. With blockchain, this process could be executed with absolute certainty of lot provenance, making recalls more effective and efficient.

In fact, the recall process has already been integrated into the blockchain by companies like Walmart, which found that recalls decreased from 7 days to as little as a couple of seconds.

An example of a blockchain network shared across organizations in the food industry (source: newfoodmagazine.com)

The greatest opportunity lies in the capture of data within the Processors and Certification blocks above. There are two main reasons why this data should be a focus, and not only for food manufacturers:

- It is already in line with your planned digital transformation, as you need to gather this data anyway.

- You may already have a lot of this data within your manufacturing facility; you just don’t know how to access it.

So what kind of information could be captured?

Primarily, information relating to methods of processing, quality control, ingredients used, and safety metrics. This data can be stored for both internal and external regulators and other interested parties. The same information can be given to certification bodies, which can use it to verify certifications such as halal, sustainable, safe, organic, or carbon-based metrics.

How can you get started with blockchain?

So, if you want to future-proof your business and be more competitive with blockchain, where should you start? Follow these steps:

- Gather data from the industrial devices that exist in your factory.

- Install gateways and sensors to gather additional data that would be valuable to both internal and external stakeholders.

- Ensure that the hardware you select is running software that is open and scalable. This will allow you to get all the benefits of regular data capture during your digital transformation and push information to a blockchain or distributed ledger when appropriate.

Thankfully, Opto 22 has numerous devices that can help you complete this job. At Ascend Data Tech (ADT), we find Opto 22’s groov RIO to be the perfect fit. It can be used as a data gateway that communicates with existing machines and can also be a customized data-gathering node utilizing local I/O (software-configurable!) to aggregate sensor data. Through the use of embedded tools like Ignition Edge, Node-RED, and MQTT, groov RIO provides everything you need for your solution to put its data into a blockchain, either when you push it ahead yourself or, potentially, when your customer/supplier/regulator requires it.

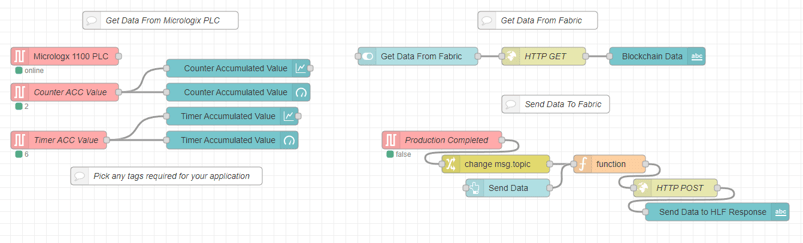

An example Node-RED flow to read data from a PLC and send it to a dashboard and to Hyperledger Fabric (source: Ascend Data Tech)

We built a proof-of-concept of the above using an approach in which the groov RIO passes data from an Allen-Bradley PLC to an active Hyperledger Fabric network using an HTTP request node and both GET and POST REST instructions. Hyperledger Fabric is a DLT with a focus on enterprise adoption, utilizing a private, permissioned ledger shared among a business consortium. We send PLC data based on a simulated trigger in Node-RED, but in a real application, you could respond to actions like production completion or the arrival of quality inspection results. Local I/O from the groov RIO could easily be added to the PoC, as well, using Opto 22's Node-RED nodes for groov I/O.

ADT is currently working on PoC’s, whitepapers, solutions, and other valuable content related to blockchain technologies. Contact us if you would like to discuss the possibilities for your organization. Or if you already have your own groov device, just follow the steps in our blog post on Industrial Data and Custom Hyperledger Fabric Networks to build your own blockchain proof-of-concept.

-- Nathan Field, Ascend Data Tech

Featured image credit: Julia Koblitz on Unsplash