Josh Eastburn

After 12 years as an automation engineer working in the semiconductor, petrochemical, food and beverage, and life sciences industries, Josh Eastburn works with the engineers at Opto 22 to understand the needs of tomorrow's customers.

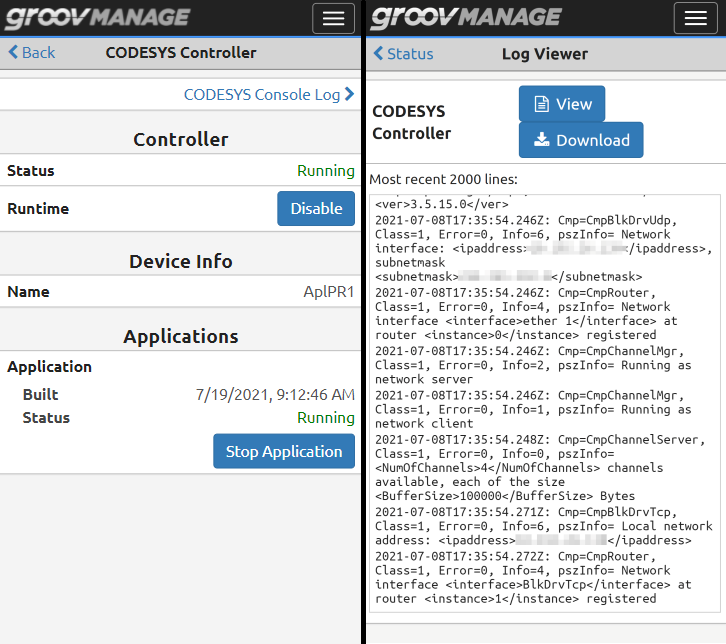

How good is CODESYS on groov EPIC? Really, really good...

If you’re a long-time CODESYS user, Opto 22 may not have come across your radar before. Here are a few big reasons why you might want to take a look at Opto 22’s groov EPIC edge programmable industrial controller and consider making it your go-to IEC 61131-3 development platform.

Read More

Topics:

Training,

CODESYS,

groov EPIC,

CODESYS blog series

Turbine control experts execute fast, cost-effective retrofit of a failing control system

RDI Controls provides fully engineered retrofit packages for industrial and aeroderivative turbine control systems. It has carried out over 160 retrofit and design projects on a variety of turbines from brands like GE, Westinghouse, Pratt-Whitney, and Rolls Royce using control systems from Allen-Bradley, ABB/Bailey, and Westinghouse/Emerson. But Opto 22 is RDI's supplier of choice, and this new case study explains why.

Read More

Topics:

Case studies,

groov EPIC,

OptoPartner

Rapid prototyping for simple (and delicious) connected control

What does it take to turn a hobby into a business? For one barbecue enthusiast, Dave Counts of Automated Concepts, Inc. (ACI) proposed using Opto 22’s groov RIO. He thought the multifunction I/O and simple Node-RED programming would provide a lot of flexibility to help his customer design a prototype barbecue control system.

Read More

Topics:

Case studies,

Node-RED,

OptoPartner,

groov RIO

Oil & Gas OEM uses integrated data and control to deliver reliable automated pressure testing

Engenuity, Inc. provides control automation and data integration solutions across several industries, with a primary focus on advanced technologies for oil & gas. You've probably seen their OptoPartner profile featured here before.

In a new case study, we dig into the details of how they use groov EPIC to design an automated solution that cuts the cost of validated pressure testing at remote well sites.

Read More

Topics:

Case studies,

OEM,

Oil & gas,

groov EPIC,

OptoPartner

New plant uses unique edge architecture to run at the pace of modern business

With demand for hand sanitizer more than doubling across the US, and continuing annual growth of more than 20% expected in coming years, 2020 presented the cleaning industry with a big financial opportunity. Emerald 66 Enterprises (E66) mobilized resources to meet this need, setting up shop in an empty denim processing plant in Seminole, Oklahoma, U.S.A.

Read More

Topics:

Case studies,

groov EPIC,

groov RIO

groov RIO enables affordable equipment-as-a-service designs that are easy to deploy

Download case study pdf

Equipment-as-a-service (EaaS) involves renting out or providing access to equipment and collecting payment periodically, rather than selling the equipment outright. This payment model enables end users to pay for costly or infrequently used equipment as an ongoing operating expense, which can open new markets for machine builders.

Read More

Topics:

OEM,

Node-RED,

groov RIO,

EaaS

One community makes the leap into MQTT-based utility management

Formally organized in 1834, Waterford Township is located geographically in the center of Oakland County, Michigan, USA, and is home to over 72,000 residents. It is known regionally for its 34 lakes, from which it earns its name.

However, in the public utilities industry, Waterford is known for its leadership and persistent innovation in water/wastewater management. The Department of Public Works has been featured previously in an Opto 22 case study, and a generation later, DPW is working on another landmark project.

Read More

Topics:

Case studies,

Water & wastewater,

MQTT,

groov EPIC,

Ignition,

digital transformation

IoT Certified OptoPartner shows us how to quickly retrofit a CNC mill with groov RIO

In a time when automation is driven by increasing connectivity, there is still plenty of everyday equipment that is simply not designed to talk to much of anything.

This equipment might be full of juicy data—how well it’s working, how much energy it’s using, how often it’s put to work—and leveraging that data to build an OEE or predictive maintenance program is often an untapped source of potential savings.

But what are your options for integrating this kind of equipment? Well, until recently they probably didn’t look very good.

Read More

Topics:

Node-RED,

OptoPartner,

groov RIO,

CNC,

OEE

Opto 22 talks connected manufacturing in the food industry.

Way back when face-to-face interviews were a thing, I had the opportunity to sit down with Pons Tugonon to talk about the development of connected food manufacturing. Pons leads OptoTech (now P&E Automation), a long-time international system integrator and distributor for Opto 22, and his work with the Mama Sita’s brand (Marigold Manufacturing Corporation) of authentic Filipino food products shows off the potential for industrial edge computing in manufacturing.

Read More

Topics:

Case studies,

Videos,

Food & beverage,

groov EPIC

Industrial edge computing enables cutting-edge indoor agricultural control and business intelligence.

Indoor agriculture is more than just greenhouses now, and for good reason. As populations grow and food demand increases, supply chains become stressed. By moving agriculture indoors, food production can happen even in the middle of dense towns and cities where many food products are ultimately bound. And unlike Mother Nature, indoor environments can be controlled for consistent, efficient, year-round production.

But as you know, not all automation is alike. Traditional control systems designed for large-scale environments aren’t well-suited to the skillset or budget of many small, indoor grow operations, but on the other hand, more affordable solutions lack centralized integration. Solutions big and small also fail to provide the security, storage, and communication features that could support useful data collection for developing business intelligence (BI).

So when MicroClimates set out to design a scalable automation and BI solution to support the growing indoor ag industry, "we went out to look for the best of breed hardware to put our software onto and that's why we ended up with groov RIO", says Loren West, MicroClimates’s CTO.

Read More

Topics:

edge computing,

groov RIO,

HVAC,

indoor agriculture

.png)