How good is CODESYS on groov EPIC? Really, really good...

If you’re a long-time CODESYS user, Opto 22 may not have come across your radar before. Here are a few big reasons why you might want to take a look at Opto 22’s groov EPIC edge programmable industrial controller and consider making it your go-to IEC 61131-3 development platform.

Deep integration

Although we released groov EPIC with Opto 22’s PAC Control as its programming tool, we designed it from the beginning to provide multiple programming options. CODESYS was an obvious choice, and we committed to making it work equally as well as our native tool.

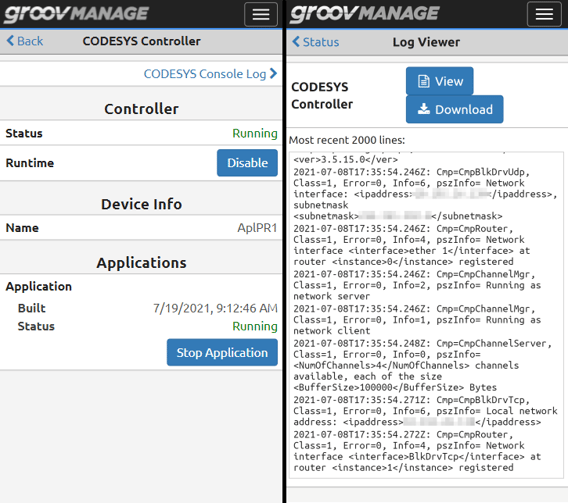

You can switch control engines quickly through EPIC’s groov Manage interface. From the same screen, you can also view and download the CODESYS runtime logs. Handy, right?

CODESYS configuration screens in groov Manage

CODESYS configuration screens in groov Manage

The only other things you need are the free CODESYS license for groov EPIC and the Opto 22 library package for CODESYS.

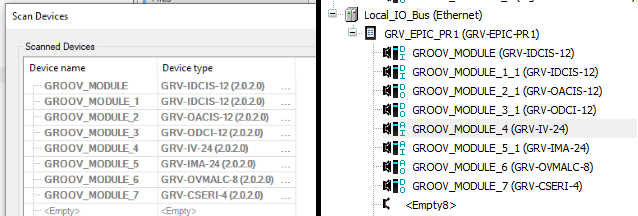

The library supports automatic I/O sensing...

CODESYS can automatically detect groov EPIC’s I/O configuration and populate the control network

CODESYS can automatically detect groov EPIC’s I/O configuration and populate the control network

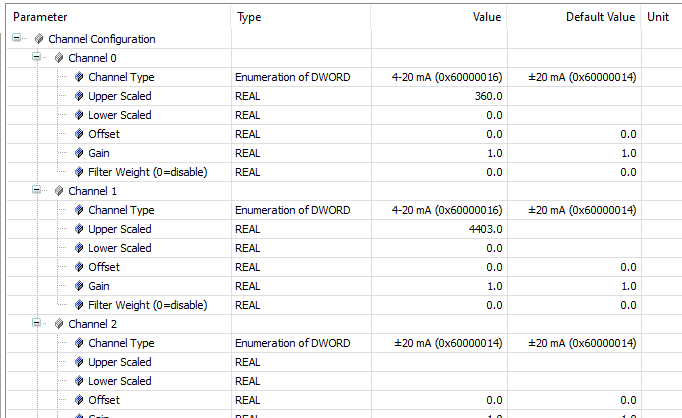

...and provides access to detailed configuration options for groov EPIC and groov RIO I/O modules, including intelligent I/O functions like scaling, clamping, and latching...

Channel options for a GRV-IV-24 module in CODESYS

Channel options for a GRV-IV-24 module in CODESYS

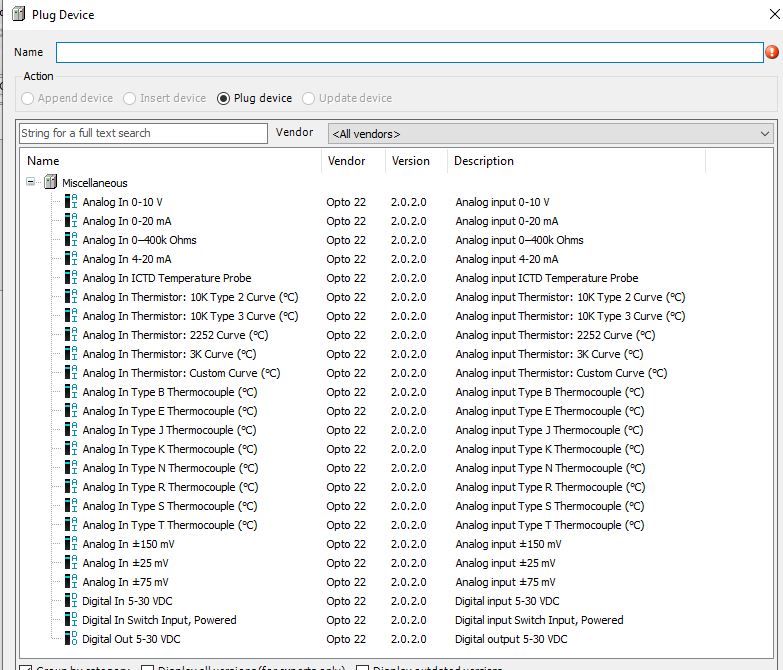

...as well as all software-configurable signal types.

In CODESYS, a single groov RIO I/O channel may provide as many as 24 different signal options

In CODESYS, a single groov RIO I/O channel may provide as many as 24 different signal options

Opto 22’s library package also includes the OSCAT basic library of over 400 functions, which we will dig into more in the next post.

Embedded applications

Edge controllers like groov EPIC rival PLCs and even PACs because they offer more functionality at a lower cost of ownership than IPCs. groov EPIC’s processing power and fault-tolerant file system support an ecosystem of embedded applications that can access program tags and I/O data via CODESYS’s built-in OPC UA server:

- groov View - Opto 22’s free, easy-to-use HMI builder can incorporate CODESYS data directly into operator screens and process visualizations. It can serve up these screens to any modern mobile or desktop browser.

- Node-RED - With an open-source library of thousands of functions for connecting to devices and services, this IoT platform can perform many useful operations on CODESYS OPC tags一like filtering noise from raw signal data, adding contextual metadata, or packaging time-series data into interoperable exchange formats like JSON.

- Ignition Edge - This suite of native protocol drivers can collect data from PLCs and field devices, including the CODESYS engine, and make it available to other modules in the Ignition SCADA/IIoT platform for MQTT communication, database transactions, MES, and more.

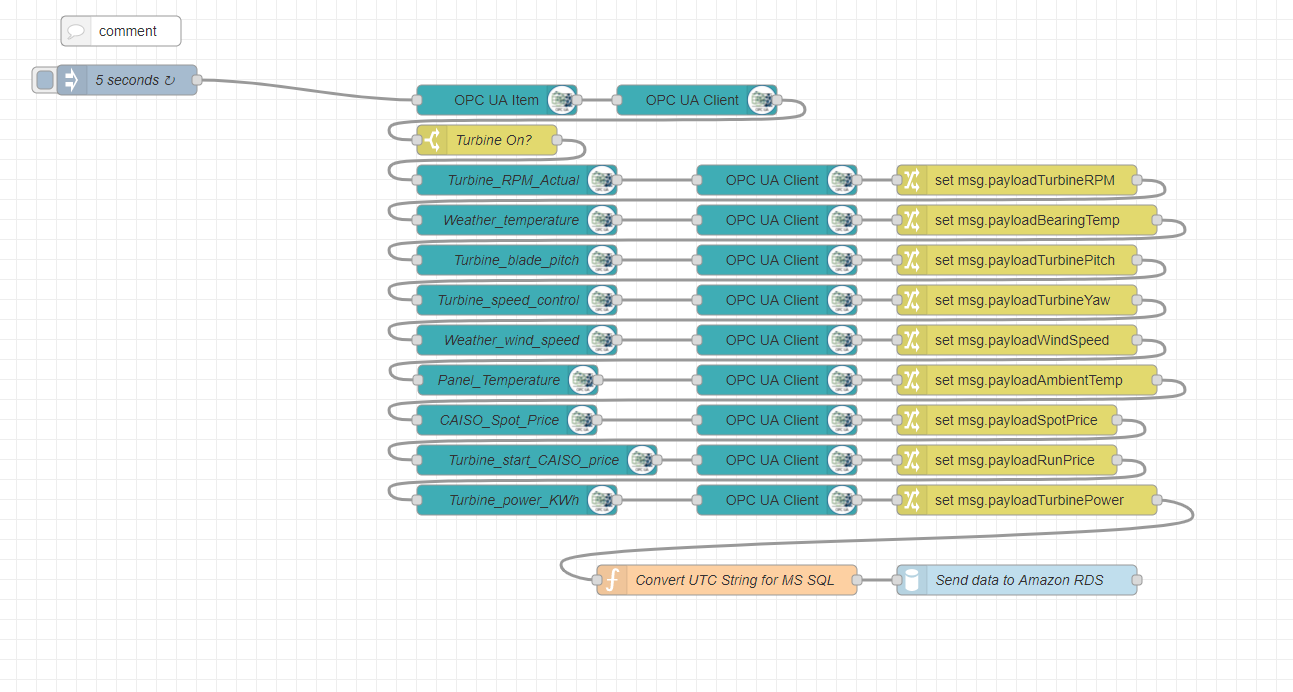

This Node-RED flow uses OPC UA nodes to pull in data from the CODESYS program and send it to a cloud-hosted database

This Node-RED flow uses OPC UA nodes to pull in data from the CODESYS program and send it to a cloud-hosted database

EPIC also provides secure shell access via SSH, so you can even build your own command-line applications that work with CODESYS data.

Security and networking

groov EPIC protects your control network using native security and networking tools. It is built on a streamlined, cryptographically signed Linux OS; authenticates external access with usernames, passwords, and/or API keys; encrypts all data communications; and blocks untrusted traffic using a configurable device firewall and independent network interfaces.

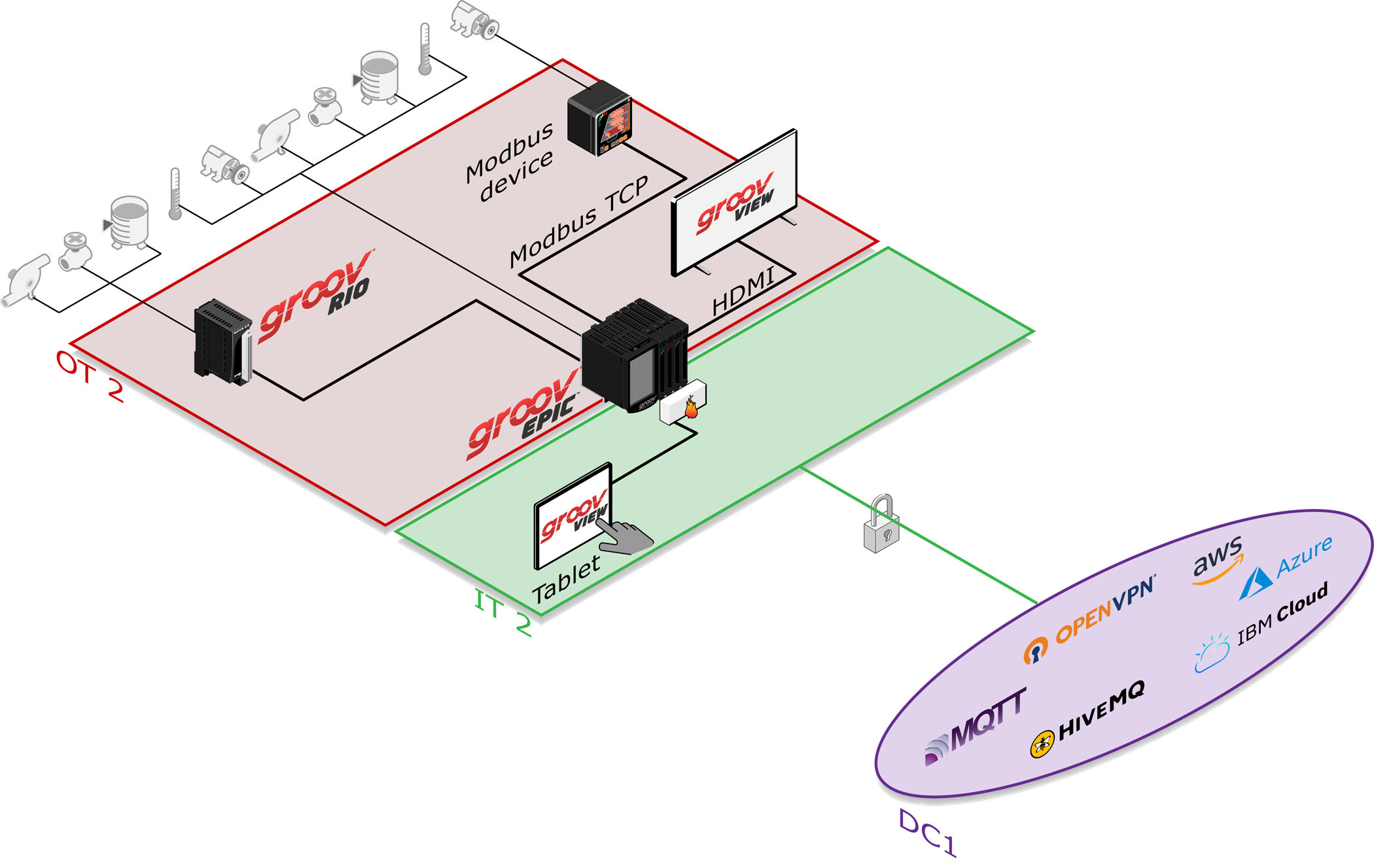

EPICs can be used to create security zones that segment automation assets from untrusted networks while also providing on-demand remote access to field devices. Tools like Node-RED and Ignition Edge support flexible network architectures. Ping, traceroute, VPN, and other networking tools are also included in the groov Manage layer.

Using EPIC, your CODESYS network is protected in a private OT zone. Access external resources through encrypted connections if desired.

Using EPIC, your CODESYS network is protected in a private OT zone. Access external resources through encrypted connections if desired.

Support and training

One final point worth mentioning is Opto 22’s approach to partnering with customers. Central to our company values is the idea that you shouldn’t need to pay us to use the product you already paid us for. (Makes sense, right?)

Our engineers are available from pre-sales through the life of the system to consult on design problems and engage with project stakeholders, all free of charge. And while we certainly recommend taking advantage of official CODESYS training resources, we always provide essential training and technical support on our products for free. It’s one of the things that keeps long-time Opto users coming back again and again.

Next time

In the next installment, we will go deeper into the CODESYS platform to introduce newcomers to the many capabilities available through its libraries. See you then!