Step inside Opto 22 HQ again for day 2 of groov EPIC training.

The Outside-In series brings you an outsider’s perspective into the way Opto 22 operates behind the scenes. Today, we’re back in Temecula, CA (not Australia… I know! I was surprised too) for the next day of groov EPIC® system factory training. If you missed the first day, the class was introduced to groov Manage and PAC Control™. Plus, we got to see Terry Orchard demo Linux® secure shell access on the EPIC.

Day 2 wraps up PAC Control and covers PAC Display™, groov View™, Ignition Edge® and CODESYS®. If you’re interested in the hands-on training available for HMI/SCADA development or IEC 61131-3 languages on the EPIC platform, keep reading.

Day 2 of 3 - Keepin’ it under control

Day 2 of 3 - Keepin’ it under control

I’m the last one to arrive this morning. The room is ready to go.

When I get to my workstation, there’s a gym bag sitting there with groov EPIC stitched on the side. Swag! If you’ve been to a few conferences or training sessions like this, then you know that bad swag is worse than no swag. Good swag is always a treat, though, and this is good. It’s heavy duty, and inside it’s full of even more goodies. (Never mind that three days later my kids sold this bag at a garage sale they put on. Let’s not dwell on the trials of parenthood.)

Back in PAC

On Day 1, we covered basic flowchart setup in PAC Control with a little OptoScript™ thrown in. While intuitive, it was new territory for me, having mostly used the IEC languages, previously. When we get into subroutines today, though, I’m pretty comfortable with the concept. It’s nice to see some structured logic in a control strategy.

A lot of the other students aren’t familiar with how to use them, though, which leads to some interesting discussion. The thrust of the conversation is why make a subroutine, when you can just make another flowchart? When we get through it, though, one student, a long-time SNAP PAC user, realizes there are Modbus communications subroutines he can simply drop into his control strategy instead of writing it all himself; he is super relieved. “[I’ve been] dreading it. I would pay you to do it for me,” he says. “It’s free!” replies Norma.

Then Norma slaps a workbook on each desk and shouts, “Time for a challenge. Get to work!” No, just kidding; Norma is always exceedingly patient. She does leave us to fly solo for a while, though. We each have a slim workbook containing instructions for building a slushy machine control strategy with multiple operating modes and level control. There’s enough detail left out that we’re forced to think through what we’ve learned so far about PAC Control. This turns out to be a nice break from the fast-paced instruction, actually; Norma switches on “Classic Rock Dinner Party,” and the room goes quiet as everyone thinks through their programs.

A new view

Done with control logic for a while, we take five and then switch to HMI development with PAC Display. Here’s something I’m familiar with. I’ve never used Opto’s HMI package, but I have developed a lot of operator interfaces over the years. With the exception of a couple quirks (where’s the Undo button?), building screens in PAC Display feels about how I would expect. We create a couple readouts for our convenience store data from Day 1, and I fiddle with the rotation and color animations until I can use the knob on my learning center to recreate a binary sunset over a Tatooine-like desert scape.

Before we break for lunch, Norma spends a little time introducing us to groov View, which I may have dabbled with in the past; I’m not sure. Compared to PAC Display, though, I’m walking on air. Drag - drop - scale - assign tags. Easy-peasy. The controls (gadgets in groov-speak) are easy to read with little design effort on my part. I can even design screens in parallel for different display sizes (PC vs mobile). And again, it’s all in the browser. Painless.

Now, I’m sure groov View isn’t all roses. My gut tells me that, with this level of polish, customization is probably difficult, where the bitmap-based packages, like PAC Display, really let you get into the nuts and bolts. I’ll look into that though and publish a follow-up post.

In any case, Norma is getting comments like, “You guys should teach Microsoft how to design a dashboard builder,” so obviously I’m not the only one who’s enjoying it.

But wait, there’s more! - The IoT Home of the... Present?!

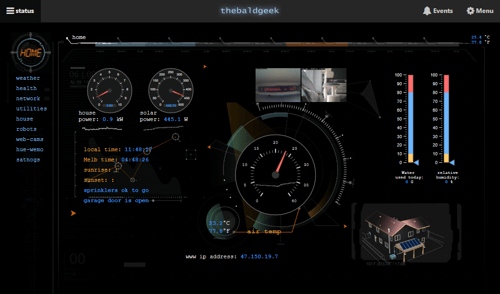

It’s been established that I enjoy lunch, but Opto is setting a higher bar than expected. For Day 2 we’re enjoying lasagna from The Olive Garden while Ben demonstrates the lengths he will go to in order to have his entire life managed in groov. “If it’s in my life, it’s got to be in groov!”

Ben is the skunkworks guy here and a devout tinkerer. His house is kind of a lab for all his interests and even a few customer applications. He has a solar array just to offset the demand his electronics put on his budget 😂

Here is a list of everything that Ben can see and/or control using SNAP I/O™, groov View, and Node-RED:

Here is a list of everything that Ben can see and/or control using SNAP I/O™, groov View, and Node-RED:- Lights

- HVAC

- Smart car

- Sprinkler system

- Solar system

- Garage door

- Water, electricity, and gas usage (w/o a smart meter!)

- Video cameras

- LED message banner

- Body health data (two wristbands plus shoe data)

- Network integrity

- Weather conditions in CA and Australia

He’s so good-natured about his addiction that it’s almost not disturbing. He clearly enjoys it, though, and the technology is super cool.

Back in the groov

When we get back from lunch, there are a lot of questions about groov View thanks to Ben, and Norma ends up demoing several other features: import/export, user access control, multiple tag data sources, animations, and event triggers for text/email notifications. The last one elicits even more comments from the class. We just connected groov View to an outbound email server and texted ourselves alert messages based on warning flags in our control strategy. “I didn’t know this was possible at the edge. I’ve always gone to the cloud,” someone says. Same here!

One more time

As if we weren’t satisfied with either of our SCADA options so far, Ben now steps in to teach us about Ignition Edge. I have spent some time with Ignition; never professionally, unfortunately, but I remember being so tickled when I heard about it that I poured a few days into their web training, trying to imagine the possibilities for such a disruptive tool. That was a few years back, before Edge, so I’m surprised and a little puzzled by the rumors I keep hearing about Ignition on-board the EPIC.

Sure enough, we’re getting right down to the nitty-gritty of setting up OPC comms and mind-controlling a little A-B PLC + stacklight setup at the front of the room. We enable Ignition from groov Manage, log into Ignition Designer, set up the PLC connection, and then add it as a new tag source in groov View. Everyone picks a light and starts flicking them on and off. “Stickin’ it to the man!” someone shouts because, yeah, it was that easy. No PLC licensing required.

Head-to-head

Obviously, looking at three SCADA packages in one day, there’s been a lot of cross-comparison. The overall split between groov View and PAC Display users is about 60/40, according to Ben, but which is best for you depends on your situation. Here’s what I learned from all the discussion:

- When it comes to historical trending, PAC Display is simply more powerful than groov View.

- Refresh rate in groov View is also limited by current browser standards, so for real-time response in a high-speed process, look to Ignition.

- Legacy operator terminals may not be up to running an HTML5-compliant browser, so stick with PAC Display, if that's your situation.

- PAC Display also uses completely different technology from groov View, so there’s no way to migrate projects from one to the other.

- However, if you’re committed to PAC Display, groov Server™ makes it easy to add a mobile interface.

- As of writing this, groov EPIC v1.4.1 firmware has been released with full Ignition support, which means you can now run the Ignition Alarms module from your EPIC and save yourself managing another Windows box. Booya!

Day 2 wrap-up

This post is going on pretty long, so I’m going to defer some of Day 2 until next time. If you were hoping to read about CODESYS, sorry, you’ll have to wait… Yes, it was a very full day, but again it surpassed my expectations as far as exposing me to big new ideas.

Next time, we’ll also dive into some hands-on work with Node-RED and MQTT, where all of this technology really comes together. Plus, Ben takes us to school one last time.

See you next time!

How about you? Are you a PAC Display user, or are you running groov View? Ignition Edge? What’s your experience like? Let me know in the comments.