In several previous posts we talked about some of the software technologies automation professionals should put on their radar in preparation for Industrial Internet of Things (IIoT) applications.

JavaScript, node.js and Node-RED offer a ton of benefits to those looking to build their IIoT application. Learn more about the Industrial Internet of Things in the State of the IIoT white paper.

Node-RED is also available as a standard feature on all GROOV AR1 Boxes from Opto 22. You can learn more about it in the video below.

Each software technology we've talked about (JavaScript, node.js, Node-RED) has a huge pool of developer talent that can be tapped into, which means you’re not going to struggle to find a developer to build your IIoT application.

Each software technology we've talked about (JavaScript, node.js, Node-RED) has a huge pool of developer talent that can be tapped into, which means you’re not going to struggle to find a developer to build your IIoT application.

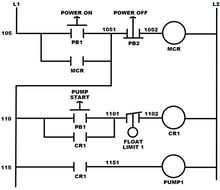

You can easily find someone in the developer market that understands these web languages and technologies, as opposed to struggling to find someone that understands legacy languages like ladder logic.

Node.js and Node-RED also offer a wealth of prebuilt code that’s already been written, so you can leverage it in your own application without a lot of effort.

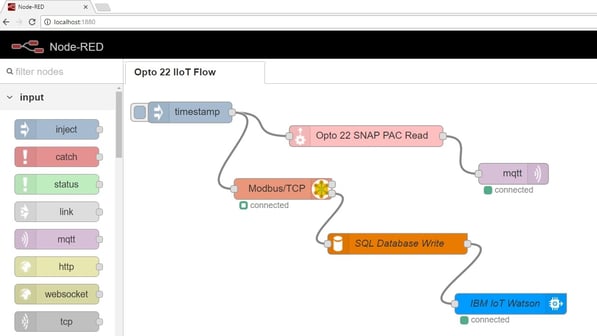

And we know that Node-RED, with its visual drag-and-drop, point-and-click interface, is an incredibly easy tool to use to build your own IIoT application without having to write and debug code.

But what are some of the nodes and Node-RED flows you might be able to use in your application? Here’s a list of ten Node-RED nodes you might find useful.

![]() Public IP Address Change. Maybe you’ve got a remote site that you’ve set up port forwarding on so you can easily remote-desktop into the HMI there. Don’t you just hate it when the ISP changes the public IP address without giving you a heads up? Getting locked out of your remote site can be a pain.

Public IP Address Change. Maybe you’ve got a remote site that you’ve set up port forwarding on so you can easily remote-desktop into the HMI there. Don’t you just hate it when the ISP changes the public IP address without giving you a heads up? Getting locked out of your remote site can be a pain.

This flow automatically checks whether your remote site’s public IP address has changed. Once the flow checks, you can automatically notify yourself over any number of methods including Twitter, email, and text message.

Log data to a spreadsheet. In this case, Google Sheets. Now you can log your data up to a spreadsheet in the cloud where you can safely store it for as long as you need to.

Check the weather. You can automatically check the weather and then control your HVAC system to change setpoints in your control system.

Transmit sensor data over MQTT. MQTT gets a lot of press these days. And for good reason. It’s an incredibly lightweight publish/subscribe data transmission protocol. You can read more about MQTT and how it compares to OPC in this Opto 22 blog post.

Transmit sensor data over MQTT. MQTT gets a lot of press these days. And for good reason. It’s an incredibly lightweight publish/subscribe data transmission protocol. You can read more about MQTT and how it compares to OPC in this Opto 22 blog post.

Report by exception. Need to add some basic report-by-exception capabilities to your control system? Do it with this Node-RED node. You can even add some additional notification capabilities like Twitter and email messaging, so you have real-time control system information wherever you are.

IBM® Watson IoT™. This is where things start to get pretty interesting, and you can take your IIoT application to an entirely new level. Watson has all kinds of tools built into it to do things like machine learning, predictive analytics, and a host of other human and machine interaction features. There are also nodes for the IBM Bluemix®system.

IBM® Watson IoT™. This is where things start to get pretty interesting, and you can take your IIoT application to an entirely new level. Watson has all kinds of tools built into it to do things like machine learning, predictive analytics, and a host of other human and machine interaction features. There are also nodes for the IBM Bluemix®system.

Just remember, you have to have data to plug into Watson to get it to do anything interesting. That’s where our next node comes in.

SNAP PAC System. Get your control system data, including I/O values and system variables, into cloud-based applications like IBM Watson or Amazon® Web Services. Read and write this data securely. Remember, to do anything interesting with the big data from our process control and automation systems, you first have to actually get the data.

Serial devices. Got some old serial devices attached to a PC that contain useful data, if only you could access it easily? There are nodes for serial devices, too. Now your serial devices can join the IIoT and become another data source for cloud-based applications.

Modbus Devices. The old fallback protocol, Modbus, often the last resort of all automation systems. If you can’t get that new-fangled, advanced, and probably totally proprietary automation protocol to work, there’s almost always the old standby available in the form of Modbus. Now you can pull data from your Modbus devices (and that’s a lot of industrial automation and process control devices) directly into your Node-RED application, where you can move it into predictive analytics software in IBM Watson IoT.

SQL and SQLite. Want to access data stored on a local database somewhere, or use it as information to help make decisions in your control system? That’s easy to do with Node-RED as well.

There are nodes for all kinds of things. The building blocks are already there for just about anyone to quickly get started with their IIoT application using Node-RED.

Learn more about the Industrial Internet of Things in the 2017 State of The IIoT Whitepaper.