The adage “what gets measured, gets managed” is an old one[1], and I had heard it many times, but a director of mine in a previous job put a new spin on it: “What gets measured, gets managed, gets improved.”

The adage “what gets measured, gets managed” is an old one[1], and I had heard it many times, but a director of mine in a previous job put a new spin on it: “What gets measured, gets managed, gets improved.”

That last bit is of utmost importance in today's environment. So many times we only follow the first two points, or only the first.

Many facilities capture every bit of data they can. Then when management goes to evaluate the data, they can’t see the forest for the trees. The huge amount of data makes it impossible to run any analyses, and we’re stuck with just the first part, getting measured.

In today's world, businesses have begun utilizing AI (artificial intelligence) in the form of IBM’s Watson, SAP HANA, and others. These have been invaluable tools, but the resources typically involved in integrating them into existing installations are cost prohibitive.

That is, until now.

Now with the growth of industrial internet of things (IIoT) and edge devices, integration is easier, giving more companies access to these analytical tools. Now instead of people sitting in a conference room poring over data, we can publish it directly to the business intelligence tools and receive real-time analytics to help improve processes. Now we can get to the parts of actually managing the processed data and developing ways to improve the system.

A capable IIoT edge device

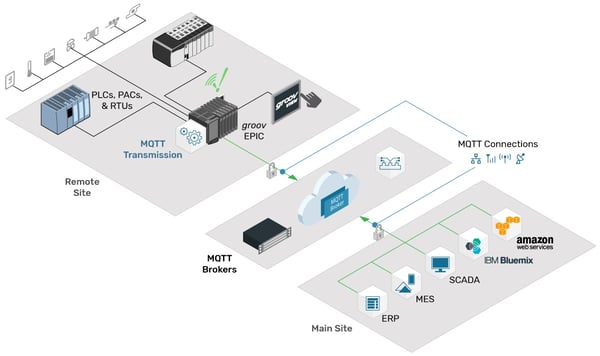

What are these IIoT and edge devices, and how do they make integration easier? Take a look at what can be accomplished in an existing site by using Opto 22’s groov EPIC Edge Programmable Industrial Controller.

As you can see, groov EPIC has the ability to directly publish data to the cloud resources that can interpret the data for you and give you that push toward improvement. Data also becomes available to MES, ERP, and SCADA solutions, so everyone within the plant—from the operators to the C-suite—who needs it has access to the pertinent information for their decision making.

All of this with one piece of hardware and some very easy-to-implement programming features, using MQTT/Sparkplug to efficiently publish and subscribe to data points and send them directly to the cloud or a local broker.

Using these features you can start to introduce the goals of Industry 4.0. The ideas of Industry 4.0 are to create smart factories using cyber-physical connections through a set of criteria: interoperability, information transparency, technical assistance, and decentralized decision making.

- Interoperability is the communication between machines, devices, and people using the IIoT. This is the first step to creating a smarter factory.

- Transparency in this context is the use of data across different machines and processes within the factory, and then gathering that data for processing and interpretation. This is the transportation of data to management, engineering, or business intelligence systems.

- Technical assistance is the ability to move from reactive or preventative maintenance on machines to a predictive style, allowing operators to have knowledge of likely issues and MTBF (mean time between failure) data.

- Decentralizing the system for decisions is using business intelligence to allow machines and people to perform tasks for the factory at a semi-autonomous level.

Of course, with any new technology or industry focus, many will push back and claim the virtues of “traditional” automation systems. I choose to look at safety, anywhere throughout history. Automobiles went from no restraints, to seat belts, to airbags, to auto-stopping, using technology.

As Maya Angelou[2] said, “Do the best you can until you know better. Then when you know better, do better.” We are at the point of knowing better; it is time to start doing better to get more out of our automation.

Using all of these ideas—and leveraging the power of the groov EPIC system—will give factories a leap into the future. You’ll have the ability to go beyond measuring and managing and start improving.

Using all of these ideas—and leveraging the power of the groov EPIC system—will give factories a leap into the future. You’ll have the ability to go beyond measuring and managing and start improving.

Learn more about the groov EPIC system.

View a live demo (username: trial; password opto22).

_________________

[1] William Thomson, the Scottish physicist also known as Lord Kelvin

[2] Maya Angelou was an American poet, singer, memoirist, and civil rights activist.