Suppose you have an analog input—maybe it's a flow meter, for example—and you want to know not only the current flow rate, but also the cumulative flow over time.

How many gallons went through that pipe over the last 24 hours, or over the last month?

If you're using an Opto 22 analog input module and PAC Control, you're in luck.

Read More

Topics:

Energy management,

Process control,

Tips,

optonews,

I/O,

PAC Project,

OptoNews 2015-12-02

Have you ever wished you could troubleshoot a networking problem faster, more accurately, and with greater efficiency? Stay tuned for the next few series of blog posts where we’ll discuss exactly how you can do that.

Have you ever wondered how data gets from one side of the Internet to the other? How an email you send from California ends up in Paris in just a couple of seconds? How your programmable automation controllers send data to your groov appliance to be displayed on your smartphone or tablet, wherever you are in the world? The magic behind all of this is called the TCP/IP model.

Read More

Topics:

IoT,

Networking

The new SNAP-OMR6T-C mechanical power relay output module offers four points to switch loads up to 6 amps at 250 VAC or 30 VDC.

AND it includes integrated transient suppression, while maintaining minimal leakage current.

Read More

Topics:

Discrete control,

optonews,

New products,

I/O,

OptoNews 2015-11-18

How do you get a variety of building systems and machinery to communicate with a central system controller, when they use different protocols?

Swedish system integrator Processcomponent AB had to solve this problem when they installed an energy monitoring system in a large apartment building in Gothenburg.

Read More

Topics:

Energy management,

Case studies,

Remote monitoring,

optonews,

Integrators,

Building management,

Modbus,

OptoNews 2015-11-18,

M-Bus

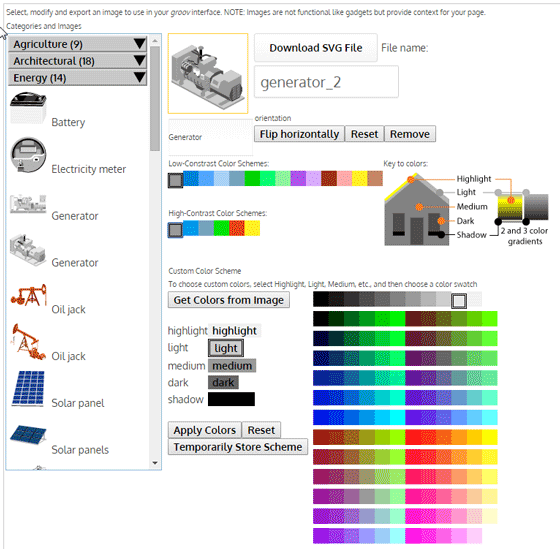

Have you discovered our secret cache of SVG images?

You can use these free images in your groov mobile operator interface or in other places where SVG (scalable vector graphics) files are supported.

Bring them into your interface and make them the size you need. Because they're SVG, they automatically scale, so they look good whether they're on a monitor or a smartphone.

Read More

Topics:

groov,

optonews,

OptoNews 2015-11-18

Do you use communication handles in your PAC Control strategy?

Or are you thinking, "What's a communication handle?"

In either case, this tip is for you.

A communication handle is a powerful type of variable in PAC Control. You'll use it for three main reasons:

Read More

Topics:

Tips,

optonews,

PACs,

PAC Project,

OptoNews 2015-11-18

If you've used Opto 22 products for a long time, you may very well have some colorful G4 digital I/O modules in a panel somewhere. They were probably installed back in the 1990s.

Still reliably monitoring sensors and activating outputs, these G4s are likely the workhorses of your automation system. Why would you ever want to replace them?

Read More

Topics:

Discrete control,

optonews,

Migration,

I/O,

PAC Project,

Optomux,

OptoNews 2015-11-04

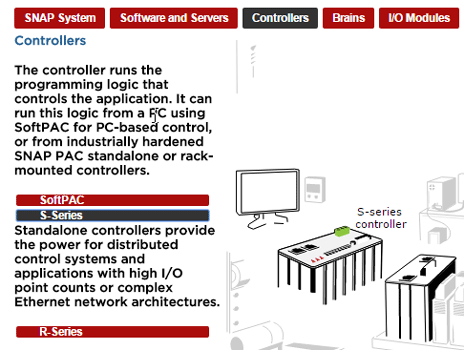

Choose the software, controllers, I/O, and more for your application, with help from our new interactive demo about SNAP PAC System components.

You'll find answers to questions like these:

Read More

Topics:

optonews,

PACs,

I/O,

PAC Project,

OptoNews 2015-11-04

Join us in Houston, Texas, November 9-12, 2015, for the ISA Process Control & Safety Symposium.

You'll learn about instrumentation, communications, control systems, safety, and security.

The symposium is geared toward engineers, technicians, and plant managers from oil and gas, refining, chemical, petrochemical, and other process industries.

Read More

Topics:

Process control,

groov,

optonews,

Events & conferences,

Oil & gas,

OptoNews 2015-11-04

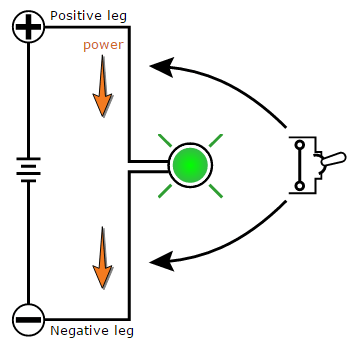

We talked about sinking and sourcing in a previous OptoNews tech tip.

But it's a subject that causes a lot of confusion, so it's worth revisiting.

Sinking and sourcing basically refer to the two methods of wiring a digital DC circuit.

Read More

Topics:

Discrete control,

Tips,

optonews,

I/O,

OptoNews 2015-11-04