Attend the Fall CODESYS Tech Talk week for a deep dive into CODESYS and real-world application stories currently using the programming tool.

When programming PLCs or edge controllers, are you looking for an open platform, device independence, and support for Industry 4.0? The CODESYS programming environment checks all these boxes.

Included as a programming option in both groov EPIC and groov RIO products, CODESYS supports all IEC 61131-3 compliant languages.

Ready for free CODESYS technical training? Hear about the 2025 CODESYS Tech Talks that Opto 22 will be participating in.

Read More

Topics:

Webinars,

Events & conferences,

CODESYS,

groov EPIC,

groov RIO

ENTELEC (Energy Telecommunications and Electrical Association) offers its annual training focused on current challenges facing the oil and gas industry.

If you're interested in digitalization and operational efficiencies, SCADA, IIoT, field communications, cybersecurity, and regulatory developments in the oil and gas industry, this one-day seminar is for you.

Hear what topics are being discussed at the annual Fall ENTELEC seminar, why you should consider a membership, and what Opto 22 will present.

Read More

Topics:

Events & conferences,

groov EPIC,

oil and gas,

ENTELEC

New case study shows how you can connect numerous remote sites into a single monitoring system.

Monitoring a solar power plant is no small task, but it’s easier when everything is in one place and under your control.

Now imagine monitoring 30 plants, built by various contractors, scattered across 3,000 kilometers (1,864 miles) of remote terrain, and using a patchwork of inconsistent control systems. Does this scenario sound familiar?

In a new case study, find out how Interlog, an IoT-Certified OptoPartner, was able to design and implement a consistent solution.

Read More

Topics:

Energy management,

Case studies,

groov EPIC,

energy monitoring

A long-standing partnership with Leuze now includes Opto 22 product distribution and system integration in Brazil.

Automation customers around the world need access to Opto 22 products, and those of you in Brazil can now contact Leuze, the new official distributor of Opto 22 products in Brazil.

Leuze has been a part of the OptoPartner system integrator network for several years, but has now grown their business to include distribution and resale.

Learn more about the company's history and experience.

Read More

Topics:

groov EPIC,

OptoPartner,

groov RIO,

OptoChannel

Here are more reasons you should attend this year's Ignition Community Conference—hosted by Inductive Automation.

Have you used Ignition software in any of your industrial applications?

Opto 22’s groov EPIC edge programmable industrial controllers and the groov RIO GRV-R7-MM2001-10 edge I/O module come with Inductive Automation’s Ignition Edge®.

Your groov EPIC or groov RIO with Ignition Edge can do things like enable data buffering, publish and subscribe to data through MQTT, supply remote alarming, and much more.

The best way to learn just how powerful this technology combination can be is by networking and learning from Ignition experts from all over the world. See what's possible at this year's Ignition Community Conference.

Read More

Topics:

Events & conferences,

groov EPIC,

Ignition,

Ignition Community Conference,

groov RIO

New case study shows how to overcome the limitations of closed, vendor-specific control systems.

Are your building automation systems ready to stand up to harsh industrial environments or unexpected power outages?

When variables like temperature or airflow are crucial, you can't afford any downtime.

That was the problem at Pearl Pharma™, a cannabis cultivator in California, whose brand-new facility didn’t work the way it was supposed to.

See how they overcame their application challenges.

Read More

Topics:

Case studies,

groov EPIC,

groov RIO

New case study explains how edge technology can help you achieve advanced data acquisition systems with real-time visibility.

If you've ever tried to manage remote operations with many service providers working in siloed systems, you understand the challenge of getting accurate data.

With a heavy reliance on manual processes, like spreadsheets and equipment with no internet connectivity, it can be a struggle to prove performance and defend business decisions.

Facing these types of challenges, Pennsylvania-based Deep Well Services (DWS) knew they needed an advanced data acquisition (DAQ) system that could survive the realities of field work. But how to do it?

Read More

Topics:

Case studies,

Oil & gas,

groov EPIC,

data visualization,

digital transformation

This webinar recording is your valuable go-to resource for accessing stranded OT data and building a UNS that's AI and analytics ready.

Did you attend this month's Unified Namespace (UNS) webinar hosted by Cirrus Link Solutions and Opto 22?

Now you can watch the webinar recording on demand.

See how to:

- Connect, collect, model, store and share OT data

- Build a unified namespace

- Go from field to cloud using tools you already know

Read more about everything you’ll learn,

packed

in

to one hour.

Read More

Topics:

Webinars,

MQTT,

groov EPIC,

Ignition,

Cirrus Link Solutions,

UNS,

Unified Namespace

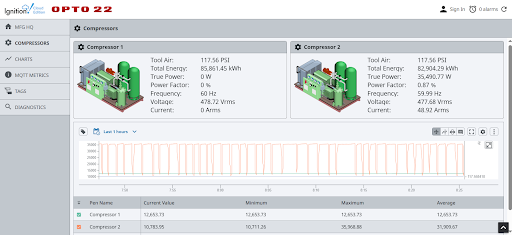

New live demo provides a practical example of how to set up machine monitoring at your facility.

Whether you're trying to cut energy costs, avoid unplanned downtime, or just get eyes on what's actually happening on the plant floor, real-time machine monitoring gives you the information you need to act.

If you're looking for a practical example of how to do it—using real equipment, standard protocols, and a system that's running 24/7—try out a new live demo that shows exactly how we’ve set up our own machine monitoring at Opto 22 headquarters in Temecula, California.

Read More

Topics:

groov EPIC,

Ignition,

Ignition Cloud Edition

New website search tools make getting help with applications from your local OptoPartners or distributors easier.

Are you needing a system integrator to help with your industrial automation projects?

You need access to companies with expertise and application experience working with all Opto 22 product lines, including groov EPIC and groov RIO.

The Opto 22 website has just been updated with new search tools that make it easy to find an OptoPartner to help you design, integrate, install, or upgrade your industrial control system.

See how to find a partner near you.

Read More

Topics:

groov EPIC,

system integrator,

OptoPartner,

groov RIO,

OptoChannel