Find added security, expanded communication options, and upgrade details in this migration tech note.

Are you holding off on upgrading your control system because you’re dreading the potential downtime? Do you think you’ll have to rip and replace your existing field wiring and I/O cabinets? Are you wondering how much of your working PAC Control logic has to be rewritten?

These are valid concerns and reasons to hesitate when touching a system that’s currently keeping your plant running. However, migrating to groov EPIC (Edge Programmable Industrial Controller) is designed to be much smoother and more flexible than a typical system overhaul.

Opto 22's Migrating from SNAP PAC to groov EPIC technical note provides the details about navigating this transition. And here are some major advantages you’ll gain by upgrading to an EPIC system.

Read More

Topics:

Migration,

groov EPIC,

snap pac

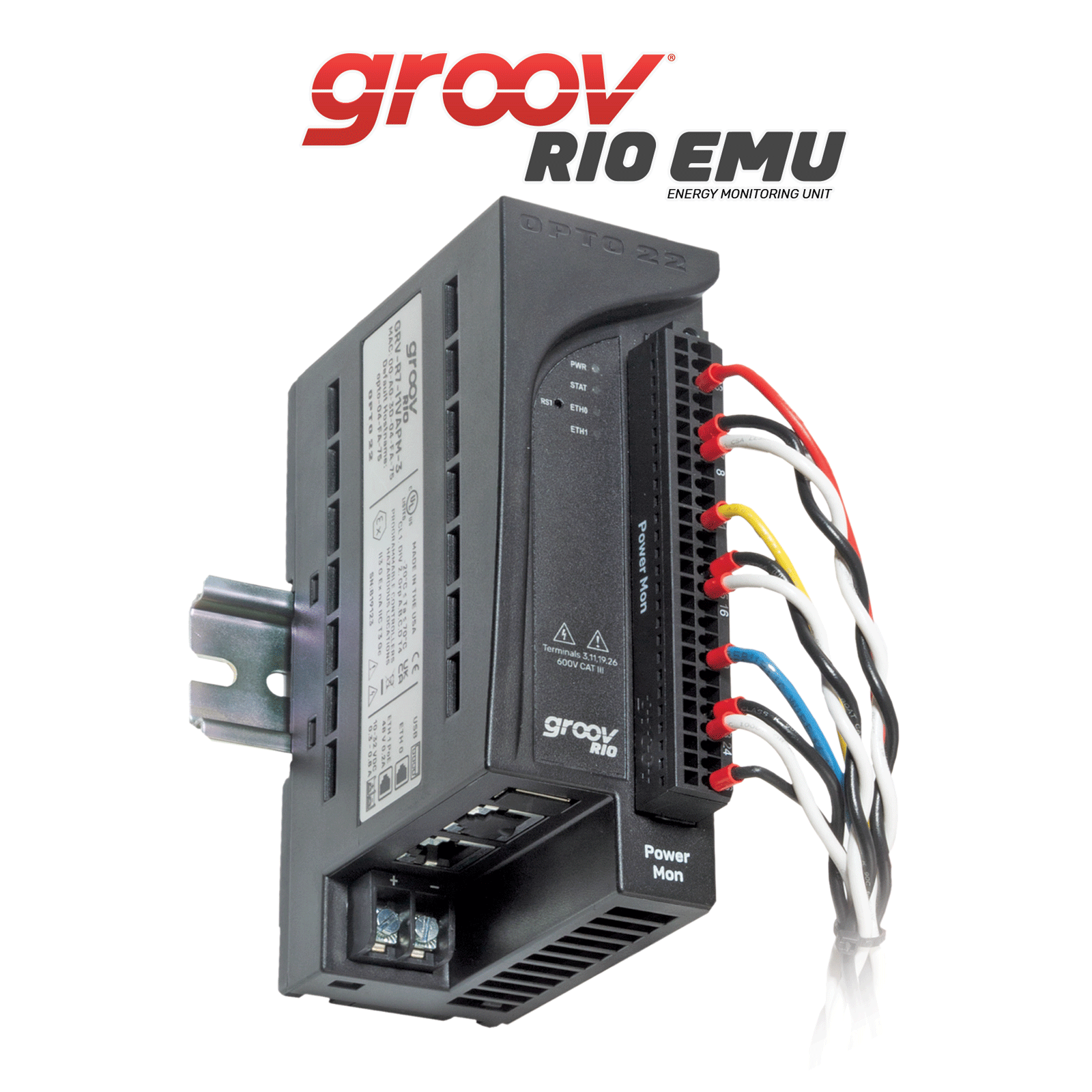

Learn how you can measure and securely manage power and energy usage data across your facility.

Are you working on machine health initiatives and predictive maintenance? Do you want to track (and reduce) operating costs?

groov products offer a simple, flexible, industrial way to monitor power and energy where it's used and securely send that data where it's needed for analysis and decision-making.

Here's your chance to learn more about the groov RIO energy monitoring unit (GRV-R7-I1VAPM-3), or RIO EMU for short. It brings connectivity to projects that require power and energy data acquisition and communication. Whether you're already using groov RIO for energy monitoring or still researching your options, the groov RIO EMU User's Guide can help you understand its full capabilities and features.

Read More

Topics:

groov rio emu,

energy monitoring

Sign up for the OptoForums and join discussions with experienced Opto 22 product users—and help other users with your insights.

You’ll see the OptoForums mentioned here on the blog from time to time, and that's for good reason. The Forums have valuable technical advice, sample code, product feature discussions, and firmware release previews that you can't get anywhere else.

The OptoForums now host over 10,000 members! A sincere thank you to all our valuable contributors. And if you're not already a member, now is the time to sign up or sign in with your MyOpto account. You can find the direct link under the Community tab on our website.

Read on to find out all the benefits of being a part of the OptoForums community.

Read More

Topics:

groov EPIC,

groov RIO,

OptoForum

Welcome newly IoT-Certified Charleston Engineering to the OptoPartner system integrator network.

Looking for assistance with a control system upgrade or a project solution utilizing groov EPIC controllers or groov RIO edge I/O modules? Charleston Engineering is well versed in the IIoT and industrial automation fields and can help you implement connected, intelligent systems.

As the latest engineering and design service to join the OptoPartner network, their team is ready to deliver solutions that last.

Learn more about Charleston Engineering and the experience and expertise that has earned them several stand-out projects in the Southeastern United States.

Read More

Topics:

Node-RED,

CODESYS,

groov EPIC,

Ignition,

system integrator,

OptoPartner,

groov RIO

Tips when using PAC Project with groov View, MQTT, Node-RED, RESTful API, and more

Are you wondering what else you can do to improve your PAC Project system’s performance? Did you optimize your SNAP PAC system and apply the same techniques to your groov EPIC system? There may be some other options you might not think of, like these:

-Moving

groov

View or MQTT to an alternate host task

-Enabling only essential tags as "Public" for Ignition or MQTT

-Scanning only PAC Control variables and tables if you’re using Node-RED

Whether you’re running an edge device like groov EPIC or a classic SNAP PAC system, performance optimization is a balance among logic, I/O communication, and HMI responsiveness. You might find some time savers in the Optimizing PAC Project System Performance technical note.

Here are a few highlights from the tech note.

Read More

Topics:

PAC Project,

Node-RED,

MQTT,

groov EPIC,

snap pac,

technical tips

Operating in Mexico and Latin America, ECON Tech offers expertise in the food, energy, mining, manufacturing, and oil & gas sectors.

The OptoPartner system integrator network is built around collaboration with organizations that bring you deep technical expertise, innovative thinking, and a strong commitment to making your projects successful.

New IoT Certified OptoPartner ECON Tech brings qualified automation professionals who understand how to solve your real-world challenges.

Learn more about ECON Tech, their application experience, and how they can help you.

Read More

Topics:

Industrial Internet of Things,

CODESYS,

groov EPIC,

Ignition,

OptoPartner,

groov RIO,

digital transformation

Learn how cutting-edge industrial devices using artificial intelligence (AI) are saving mining companies thousands through early leak detection.

Are you in an industry with strict regulations that require constant remote monitoring? That's what several companies are facing in Peru's mining region.

With miles of mining pipelines in Peru, national regulations require continuous monitoring to prevent spills and ensure safe operation. For mining companies, this means the search is on for practical, cost effective, and sustainable solutions to meet these standards.

Learn how OptoPartner PK Soluciones took on the challenge of stopping pipeline leaks before they stop production.

Read More

Topics:

Case studies,

Node-RED,

CODESYS,

groov EPIC,

python,

AI,

mining

Add industry trade events to your schedule this year and learn ways to make your 2026 projects more successful.

Looking for educational conferences and seminars to attend this year? Ready to find an advanced solution for your industrial automation application? Start with Opto 22's 2026 event schedule and see if groov EPIC and groov RIO product demos are coming to a venue near you.

The first stops will be in Dallas and Salt Lake City. For most of these events, you'll find us working alongside our technology partner, Inductive Automation. Come see groov product demos in person and in collaboration with Ignition software.

Read on to get registration and agenda details on upcoming shows, and we hope to see you on the road with us in 2026!

Read More

Topics:

Events & conferences,

groov EPIC,

Ignition,

groov RIO

Tune in to the latest Manufacturing Hub podcast for insight on how to digitally transform today's plant floors and get valuable, secure data from legacy systems.

Most manufacturing plants aren’t greenfield facilities filled with brand-new automation. They’re a mix of legacy machines, isolated control systems, and manual processes that were never designed to support analytics or AI.

If you're looking for advice on bridging the gap of legacy automation systems to modern, data-ready operations without breaking what already works, then you'll want to listen to the recent discussion Opto 22's Benson Hougland had with the hosts of the Manufacturing Hub podcast, Vlad Romanov and Dave Griffith.

Tune in for some straightforward tips on how to digitally scale and access the right data from your systems.

Read More

Topics:

cybersecurity,

podcast,

digital transformation,

smart manufacturing,

manufacturing

New document outlines how groov products are being used in 21 CFR Part 11 approved applications.

If you work in pharmaceutical or biotech manufacturing, you’ve probably had to think about 21 CFR Part 11, the FDA regulation that governs electronic records and electronic signatures.

Most of the Part 11 requirements live in supervisory systems like SCADA, MES, and historians. But those systems depend on one thing: reliable, traceable data from the equipment layer.

That’s where Opto 22’s groov platforms come in.

Read More

Topics:

groov EPIC,

groov RIO,

groov rio emu,

21 CFR Part 11