This latest video in our Automation 101 series provides a deeper dive and explanation of the MQTT central server, or the "broker".

As you recall from previous posts, the industrial MQTT communication protocol is a powerful tool that allows you to exchange device data freely among devices and applications, with little or no IT involvement. Its simplicity and flexibility make it a popular choice for today's IIoT applications.

Read More

Topics:

Videos,

IIoT,

Industrial Internet of Things,

MQTT,

groov EPIC,

developer

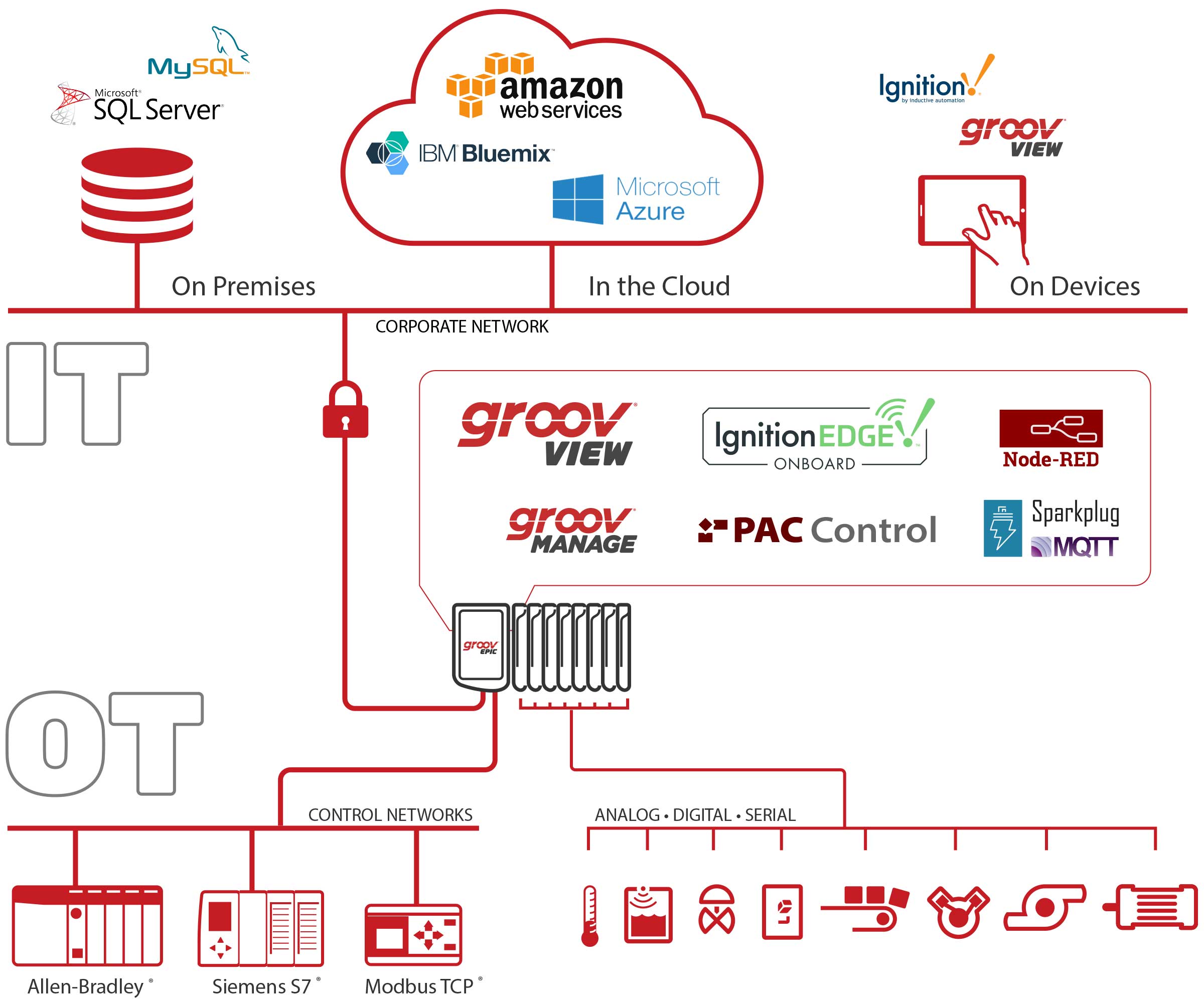

Have you ever been stuck on a coding problem? Unsure of which tool to use for an application? Or if you have the functionality you need to get the job done? Maybe you’ve just got a new system and need a map to help you learn the new features and functionality.

Read More

Topics:

PAC Control,

REST API,

Node-RED,

MQTT,

Ignition Edge,

IEC 61131-3,

groov EPIC,

developer

Make plans to join us February 4th-8th, 2019 at one or both of these industry events as we unveil an expanded groov EPIC product line and system features.

Don't miss an opportunity to meet with other leaders in the automation industry as the 23rd annual ARC Industry Forum returns to Orlando. This year's event focuses on "Driving Digital Transformation in Industries and Cities".

Read More

Topics:

IIoT,

Industrial Internet of Things,

MQTT,

Ignition Edge,

groov EPIC,

ARC Forum

The industrial MQTT communication protocol is a powerful tool that allows you to exchange device data freely among devices and applications, with little or no IT involvement.

Its simplicity and flexibility make it a popular choice for today's IIoT applications. Adding the open-source Sparkplug specification to MQTT adds even more structure and better support for industrial applications.

Read More

Topics:

IIoT,

Industrial Internet of Things,

MQTT,

Ignition Edge,

groov EPIC,

Sparkplug

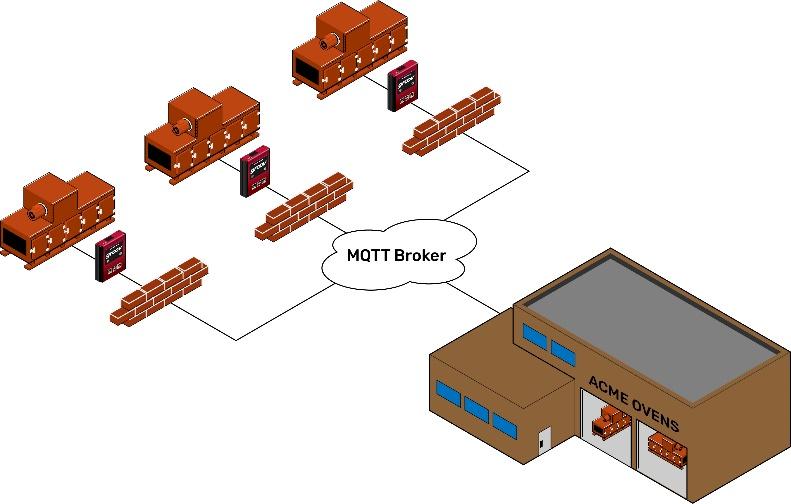

Your industrial plants and facilities produce a lot of data that you could use for improving processes, reducing maintenance costs, and making better business decisions. But securely getting that data from the sensors, transmitters, and analyzers that produce it to the people who need it can be difficult.

Read More

Topics:

PACs,

IIoT,

Industrial Internet of Things,

MQTT,

EPIC,

groov EPIC,

Big data

Working in systems integration often means putting on many hats. Sometimes you can just fulfill your normal duties of designing, building, and commissioning a controls/automation system.

But then other times you find yourself thrown into the mix as the sales estimator—asked to come up with a budgetary number for a project—or you’re deemed the “IT” person for a project.

Being designated the “IT” person can be a difficult road to navigate. Often you’re not truly an admin on any given network, but you’re asked to perform the duties of an admin.

Read More

Topics:

groov,

Internet of Things,

Remote monitoring,

IoT,

Integrators,

IIoT,

Industrial Internet of Things,

Data acquisition,

MQTT,

EPIC

With the growth of the industrial internet of things (IIoT) and edge devices, are you looking for better ways to access your data? Opto 22's new groov EPIC system includes the Node-RED environment with the MQTT transport protocol for efficient publish/subscribe data communications. Watch this new video to see how it works!

Read More

Topics:

Videos,

groov,

IIoT,

Industrial Internet of Things,

Node-RED,

MQTT,

EPIC

The adage “what gets measured, gets managed” is an old one[1], and I had heard it many times, but a director of mine in a previous job put a new spin on it: “What gets measured, gets managed, gets improved.”

Read More

Topics:

groov,

Internet of Things,

IoT,

IIoT,

Industrial Internet of Things,

Data acquisition,

MQTT,

EPIC

Looking to learn more about IIoT technologies, control systems, and how they work together? It’s time to check out OptoU!

This free online training program provides convenient, on-demand training courses to fit in with your busy schedule. With its “watch and learn” premise, course topics are made up of video and written lessons. The secure sign-in feature lets you return to unfinished lessons and learn at your own pace.

Read More

Topics:

PACs,

Networking,

Training,

I/O,

Security,

IIoT,

Industrial Internet of Things,

Node-RED,

MQTT,

Ignition Edge,

EPIC

Day in and day out, I work alongside machine builders who share a common problem: Once equipment has been shipped to a customer site, it is quite difficult to ensure that it is running properly and being adequately maintained.

I once heard the phrase, "even a Cadillac will fail prematurely if you drive it into a brick wall." Premature failure of the machinery (regardless of whose fault) can tarnish the image of the manufacturer, lead to increased warranty costs, and create tension between OEMs and end users.

But how do I (the machine builder) get access to the control system if it is operating inside a customer’s firewall?

Read More

Topics:

Remote monitoring,

Machine builder,

OEM,

IIoT,

Industrial Internet of Things,

Node-RED,

Data acquisition,

MQTT,

EPIC