In this blog post, let’s take a closer look at user accounts on the groov EPIC system, and how you can improve your system security by giving users and services fine-grained access to applications running on EPIC. In other words, make sure each person or service has only the access they really need and nothing more.

But before we get deep into user accounts, let’s first discuss user account credentials. Take a moment and ask yourself the following questions:

- Do you use the same password for multiple accounts?

- Do you use a mix of punctuation and capital letters in your passwords?

- Do you use long phrases as your passwords?

Read More

Topics:

Security,

groov View,

groov EPIC,

groov Manage,

cybersecurity,

EPIC Security,

User Accounts,

EPIC Security Series

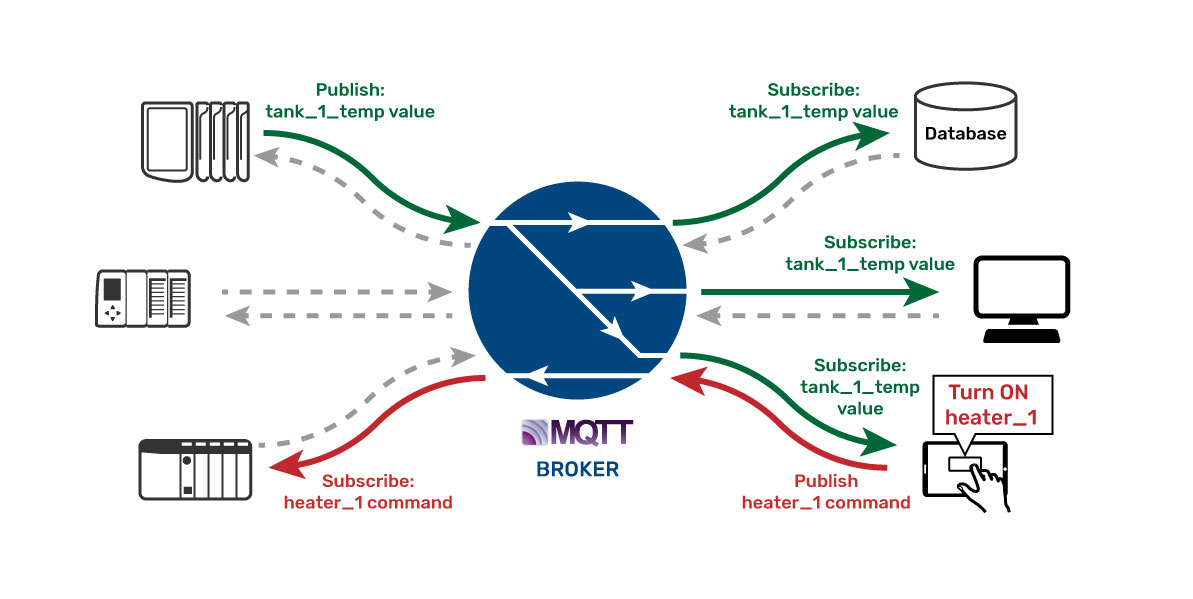

The story goes that a valve manufacturer wanted to have their networked smart valves certified for use in a nuclear reactor plant. The smart valve could report all sorts of critical data points to a database system and also be controlled by that SCADA system in the plant. But to get it certified for use, the smart valve had to undergo a rigorous security audit by the information technology (IT) department at the plant.

Read More

Topics:

Security,

MQTT,

groov EPIC,

cybersecurity,

firewall,

EPIC Security,

EPIC Security Series

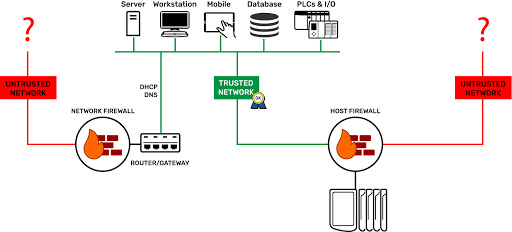

Ever notice how emergency exits in a building open outward? Then, to keep the building secure, they are usually locked from the outside. You can get out easily enough, but you can’t get in that way.

However, on a building’s main front entrance, the door often swings in so you can enter. Typically, there is a security guard or perhaps a receptionist there to check your ID and keep an eye on the comings and goings.

Read More

Topics:

Security,

groov View,

groov EPIC,

groov Manage,

cybersecurity,

firewall,

EPIC Security,

EPIC Security Series

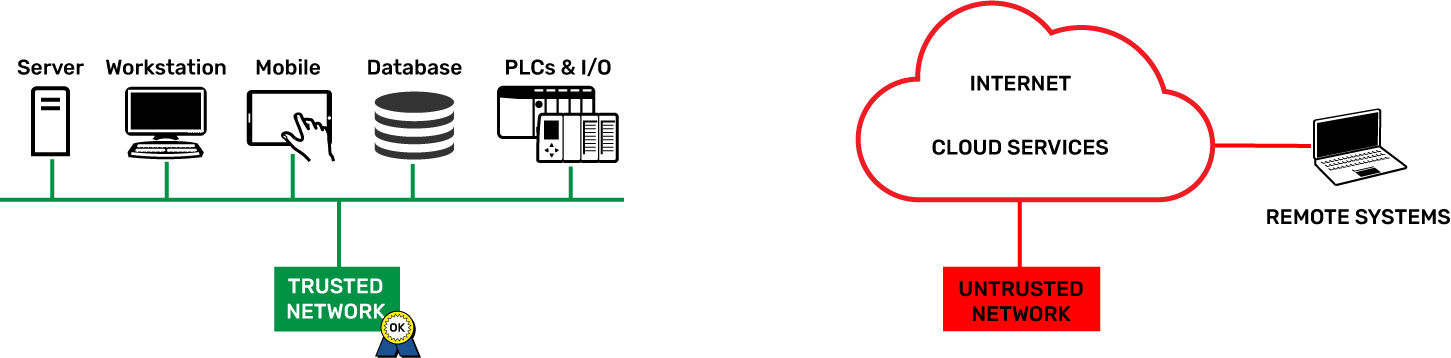

Trusted and untrusted: when it comes to people, it can be hard to know someone at first pass. You need some time to build a picture of the person.

When it comes to networking, it’s a little more cut and dried. You either know who’s on a network or you don’t.

Can it really be that simple? Is there really a way on a groov EPIC to keep those you don’t trust away from those you do?

Read More

Topics:

Security,

EPIC,

groov View,

groov EPIC,

cybersecurity,

EPIC Security,

EPIC Security Series

Sinking or Sourcing?

Let’s take a quick look at the topic of sinking and sourcing outputs.

Where did the difference come from, and where does it matter in automation?

Quick answer: you often have to choose the correct module because the device you are wiring requires either a sink or source. For example, if you have a prebuilt electrical cabinet, it may be wired using a common positive or a common negative method. Thus you HAVE to choose the correct digital output module for the way the panel is wired.

Read More

Topics:

PLCs,

Electronics,

Tips,

IoT,

Machine builder,

OEM,

I/O

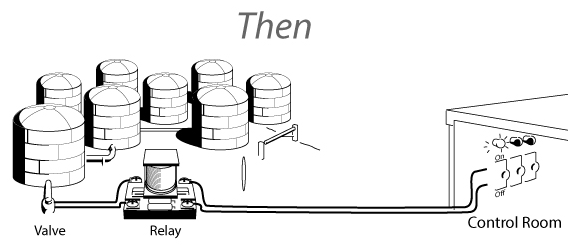

The Case for Intelligent I/O Systems.

The automation PC is located in the control room, and the dump valve is on the other side of the tank farm wired to a remote I/O cabinet, all connected over an Ethernet network.

The IT guys are working on the network, and they say it may take a few days to track down the intermittent cable. But hey, in the meantime, they say that it mostly works…

That answer might be sufficient for watching YouTube, but it is just not going to cut it for controlling that valve.

What do you do?

Read More

Topics:

Discrete control,

PLCs,

Remote monitoring,

Tips,

IoT,

PACs,

OEM,

I/O

Do what when:

In last week’s blog we covered

how to set the real time clock (RTC) in a PAC Controller with an accurate time server over the Internet using SNTP.

Now that our controller knows exactly what time it is, how do we turn on that pump at 6:00 a.m. on the dot?

Like most aspects of programming, there are a few different ways to achieve the same result, so join me in this week’s blog while we look at one way to manage real-time scheduling.

Read More

Topics:

Energy management,

Process control,

groov,

Internet of Things,

Tips,

IoT,

PACs,

PAC Project

What time is it?

Do you know what time it is? Does your SNAP PAC controller know what time it is? Are they the same time? Who’s right?

In this week's blog we are going to talk about this big ball of wibbly wobbly timey wimey stuff.… No, not time travel, but actual time…. Specifically how to set your PAC Controller to the current time.

No reading ahead; remember, time flies like an arrow and fruit flies like a banana.

Read More

Topics:

Internet of Things,

PLCs,

IoT,

PACs,

OEM,

Networking,

PAC Project

More information in less space.

It is amazing how sometimes similar applications can come back to back….Last week's blog came from a customer asking how to measure the main power grid frequency. And later the same week I had a totally different customer ask me about how he could display upper, lower and current value of the main electrical grid frequency in groov. What are the chances of that!!??

This customer wanted one gadget to display all three values. Why so dense? Because they only use groov on smart phones, no PCs or Tablets. He was polling the data from a bank of UPSes and so needed to display a lot of data. Screen real estate is prime on those devices. What can we do to help?

In this week's blog, we are going to have some adventures in Z-Order.

Read More

Topics:

Energy management,

groov,

Internet of Things,

Remote monitoring,

Tips,

IoT,

PACs,

OEM,

I/O

50 or 60 Hertz - Roughly.

Measure the main power grid frequency, he said. It will be fun, he said…. Actually, pretty sure I said something like, “it will be easy”... and I was mostly right, and best of all, it did turn out to be fun!

It seemed like both a reasonable and easy request. The requirements were to measure the mains power grid frequency to a resolution of 0.01 Hertz, and to do it every 125 milliseconds (roughly; it could be a max of 200 milliseconds, but not much longer).

Why? In this case, the chase is better than the catch. It's enough to say the customer had his reasons, and this blog is about the chase.

Read More

Topics:

Energy management,

Process control,

groov,

Internet of Things,

Remote monitoring,

Electronics,

Tips,

IoT,

OEM,

I/O