Do what when:

In last week’s blog we covered

how to set the real time clock (RTC) in a PAC Controller with an accurate time server over the Internet using SNTP.

Now that our controller knows exactly what time it is, how do we turn on that pump at 6:00 a.m. on the dot?

Like most aspects of programming, there are a few different ways to achieve the same result, so join me in this week’s blog while we look at one way to manage real-time scheduling.

Read More

Topics:

Energy management,

Process control,

groov,

Internet of Things,

Tips,

IoT,

PACs,

PAC Project

Next time you buy a SNAP brain or SNAP PAC R-series controller, you may notice something new: an aluminum base plate instead of the older black or blue plastic one.

We're constantly looking for ways to improve our existing products (as well as designing new ones), and this change is one result.

While our SNAP brains and rack-mounted controllers were already very noise immune, the new addition of an aluminum base makes them even more immune to electrical noise.

Read More

Topics:

Updates,

optonews,

PACs,

OptoNews 2015-08-12

Here's an opportunity to learn how to increase manufacturing throughput, improve safety, and optimize your production through technology: the SORT Technology Showcase 2015.

You'll see the latest technical advancements from a variety of suppliers. Opto 22's Arun Sinha will demonstrate how easy it is to put your system on your smartphone or tablet with a groov mobile operator interface.

Read More

Topics:

groov,

optonews,

PACs,

Events & conferences,

I/O,

OptoNews 2015-08-12

What time is it?

Do you know what time it is? Does your SNAP PAC controller know what time it is? Are they the same time? Who’s right?

In this week's blog we are going to talk about this big ball of wibbly wobbly timey wimey stuff.… No, not time travel, but actual time…. Specifically how to set your PAC Controller to the current time.

No reading ahead; remember, time flies like an arrow and fruit flies like a banana.

Read More

Topics:

Internet of Things,

PLCs,

IoT,

PACs,

OEM,

Networking,

PAC Project

More information in less space.

It is amazing how sometimes similar applications can come back to back….Last week's blog came from a customer asking how to measure the main power grid frequency. And later the same week I had a totally different customer ask me about how he could display upper, lower and current value of the main electrical grid frequency in groov. What are the chances of that!!??

This customer wanted one gadget to display all three values. Why so dense? Because they only use groov on smart phones, no PCs or Tablets. He was polling the data from a bank of UPSes and so needed to display a lot of data. Screen real estate is prime on those devices. What can we do to help?

In this week's blog, we are going to have some adventures in Z-Order.

Read More

Topics:

Energy management,

groov,

Internet of Things,

Remote monitoring,

Tips,

IoT,

PACs,

OEM,

I/O

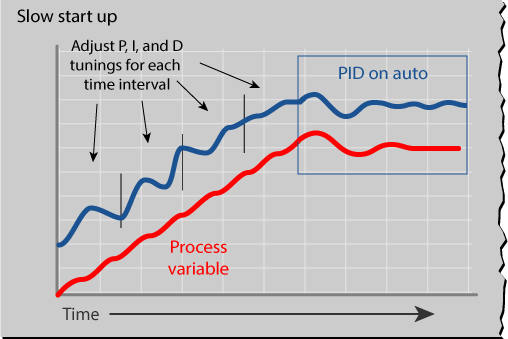

Loop the loop.

PID loops are used in a lot of different applications, and for good reason: they help keep our world under control. If you need to control a process temperature or pressure, you probably are going to use a PID loop. But are they always the right solution?

Ultra quick review; a proportional-integral-derivative control loop (or

PID controller) compares a setpoint against a measured input value, and depending on the error, changes a control variable (output). It’s all about math. A PID loop is all about running a mathematical formula over and over at a specific rate.

The most common example of a PID loop that I often talk about in our monthly training class is the cruise control on a car. The speed of the car is the input, the accelerator is the output and the setpoint is what speed the car is doing the moment the driver presses the “set” button.

PID loops are so useful that sometimes we too quickly decide to use a one in a process when it may not be the best solution to the problem. In this week’s blog we are going to take a look at one instance where use of a PID loop may not be the best tool for the job.

Read More

Topics:

Process control,

PLCs,

Remote monitoring,

Tips,

IoT,

PACs,

I/O

Plan ahead to enjoy the fall color and learn about Opto 22's versatile SNAP PAC System at the same time this September.

Whether you're monitoring remote pumps and valves, tracking energy data, controlling processes in a large factory, or doing a wide variety of other automation tasks, you'll find the SNAP PAC System reliable and scalable.

Read More

Topics:

Case studies,

groov,

optonews,

PACs,

Training,

OptoNews 2015-07-15,

I/O

Star Struck:

From a young age I have been looking up at night. Not sure exactly when I fell in love with astronomy, but I can recall looking up at the stars every chance I got as a kid.

I have ebbed and flowed with the amount of time and equipment I have had to spend on the hobby. In Australia I had a fully enclosed fiberglass domed observatory, which I chose to not ship over when my family moved to The States, but the desire to look up has not gone away.

Only the constellations at the horizon can be seen in both hemispheres, and even those look upside down compared to what I used to see. So I wanted to get something up and running fast here that would allow me some time to get my bearings in the sky and to share my new stars with my mates back in Australia via my personal website.

In this week's blog, I would like to share what astronomy tools I currently have set up, thanks to some Opto 22 hardware and groov.

Read More

Topics:

Videos,

Process control,

Discrete control,

groov,

Internet of Things,

Remote monitoring,

Electronics,

Tips,

IoT,

PACs

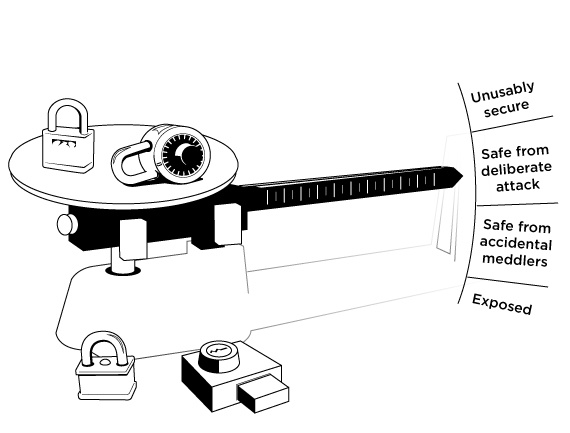

Layers of security:

I wish there were, but there just isn’t.... There is no one device, hardware, or software that is the single defense for all known and future network attack vectors—including the one critical weakness: humans. You know, some thing or device that you could simply put at your network's front door and have it reject all the bad guys, but allow the friendlies in without question. Secure and easy is still a wish.

The solution then really comes down to layers. Adding layers that each will take a lot of time and a lot of effort to peel back, so much so that most attackers simply give up and move on.

The past few blog posts have talked about some of those layers, so let's now put it all together and see just how we might go about building a very robust mobile-accessible industrial automation network.

Read More

Topics:

Process control,

Discrete control,

groov,

Internet of Things,

PLCs,

Remote monitoring,

Electronics,

Tips,

IoT,

Machine builder,

PACs,

OEM,

Integrators,

Networking

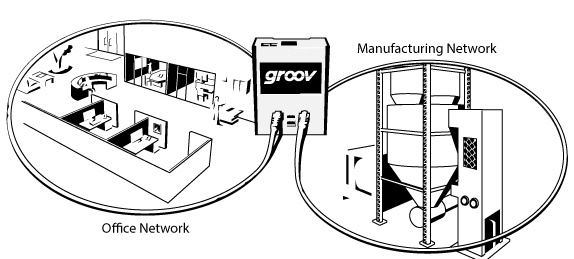

Tale of two LANs

Would you like to view critical plant status from anywhere on the Internet?

Are you worried that if you connect your automation network to your company’s IT network (which is likely connected to the Internet), the wrong people could access your control system? Or that traffic like YouTube might impact your automation network throughput?

Would you like to get an email or text message alerting you to an out-of-band condition, but since your automation network is not linked to the IT department email server, you can’t set anything like that up?

There are a lot of advantages and only a few disadvantages to segmenting your IT (Information Technology) network from your OT (Operational Technology, in other words your controls) networks. While there are a few different ways to segment networks, in this blog we are going to look at separating them using one of two Opto 22 products: SNAP PAC Controllers and groov.

Read More

Topics:

Process control,

groov,

Internet of Things,

Electronics,

IoT,

Machine builder,

PACs,

Networking