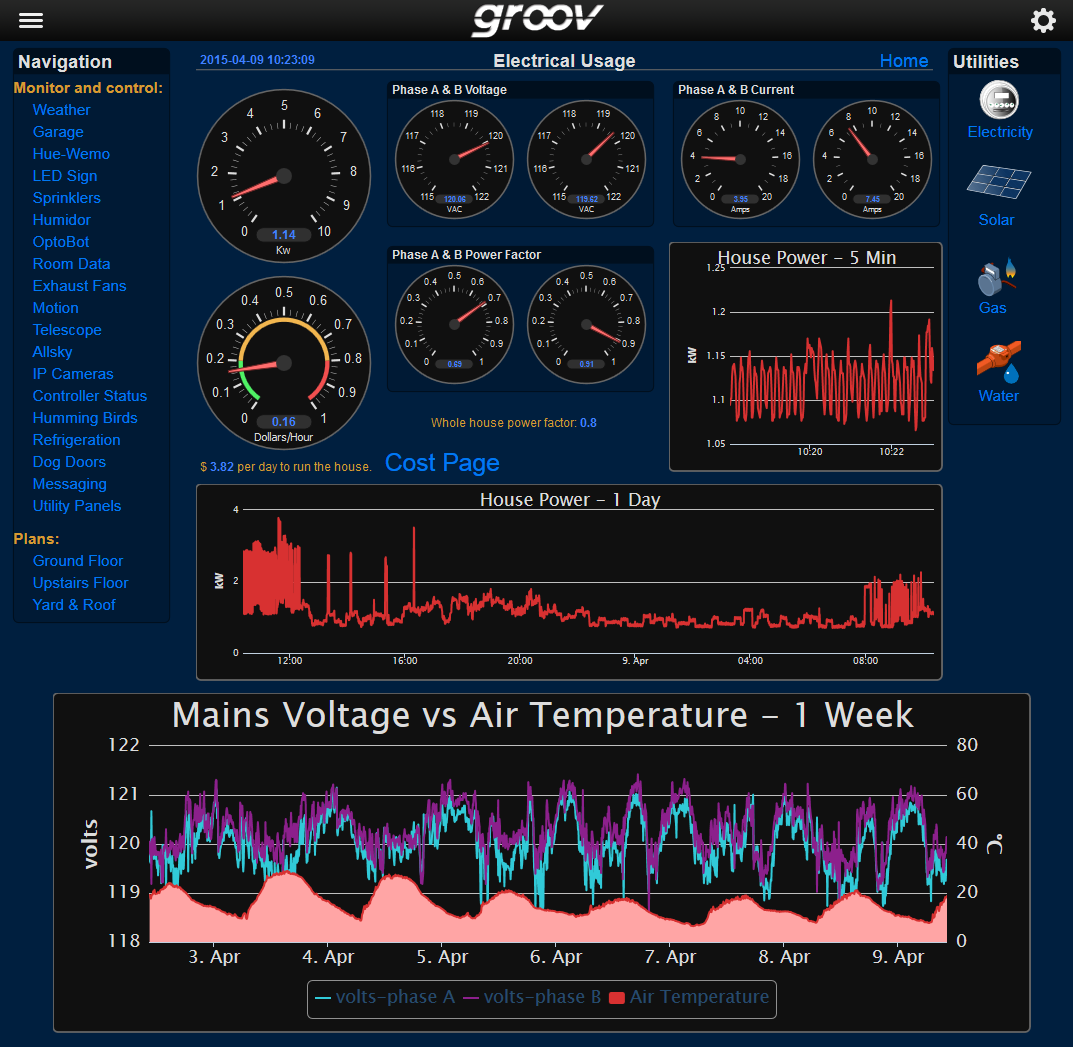

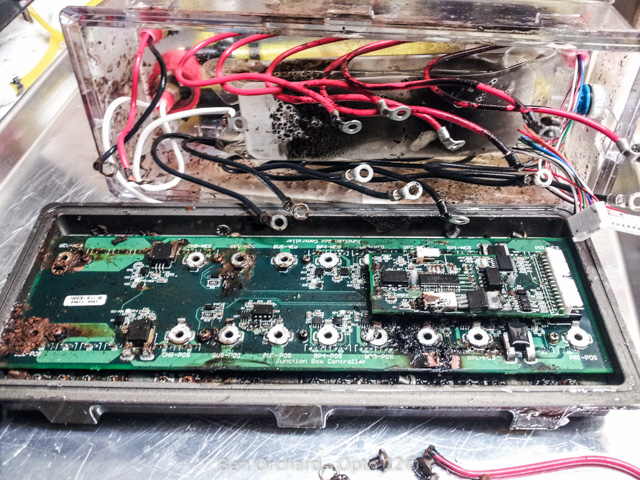

Get a mop, I spilt some electricity:

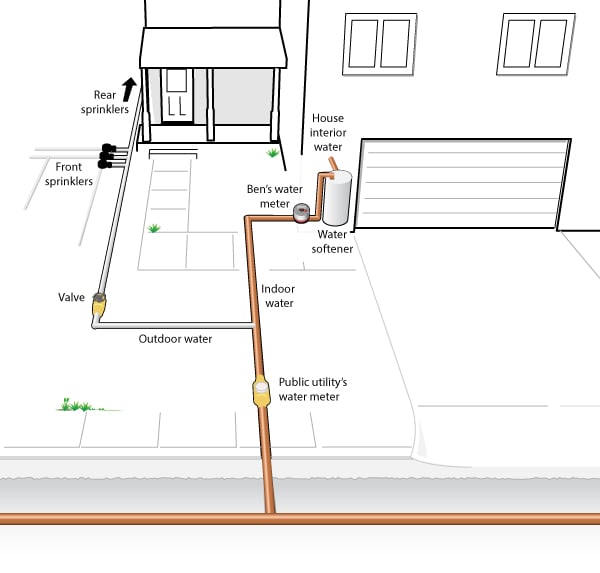

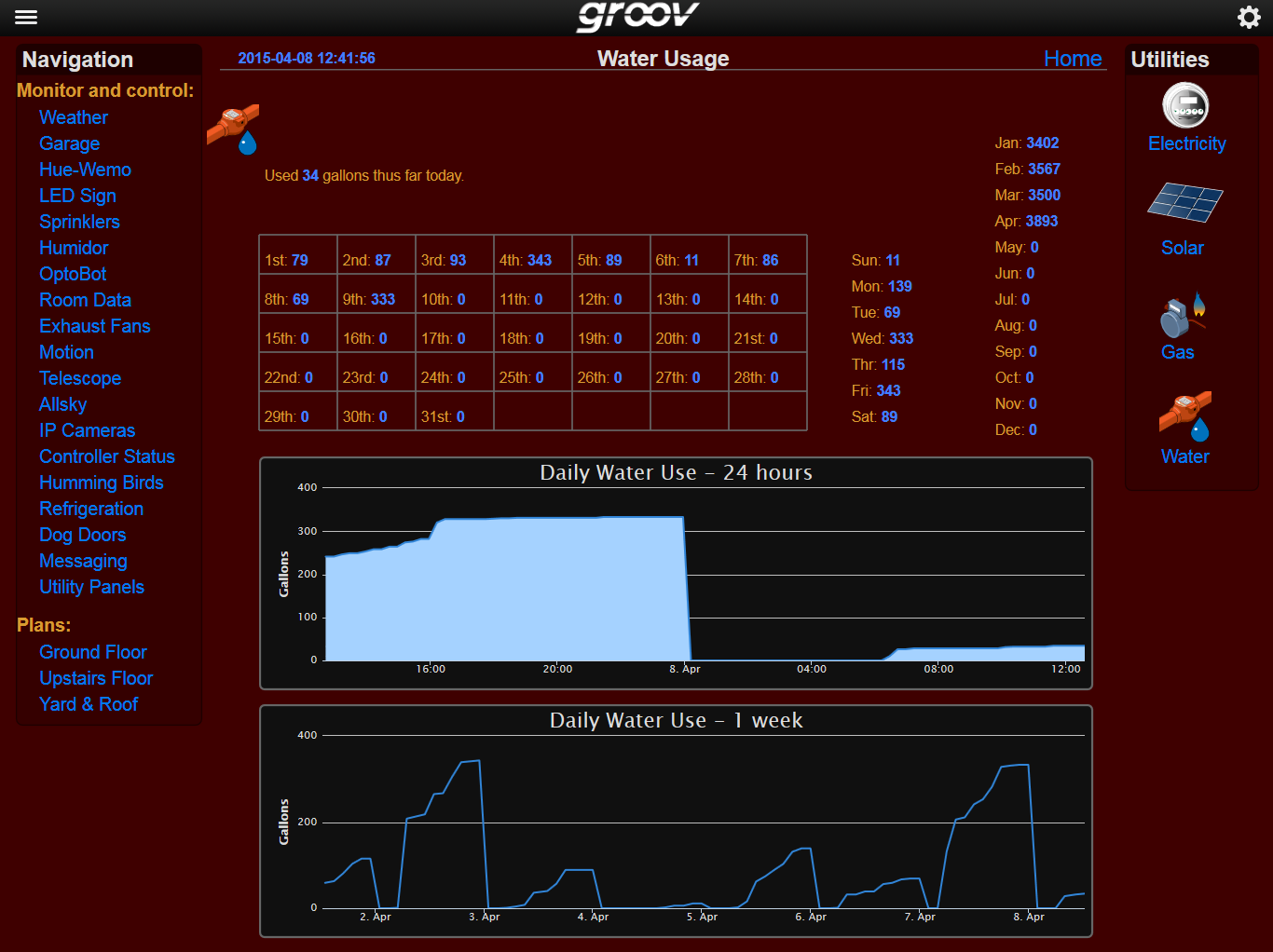

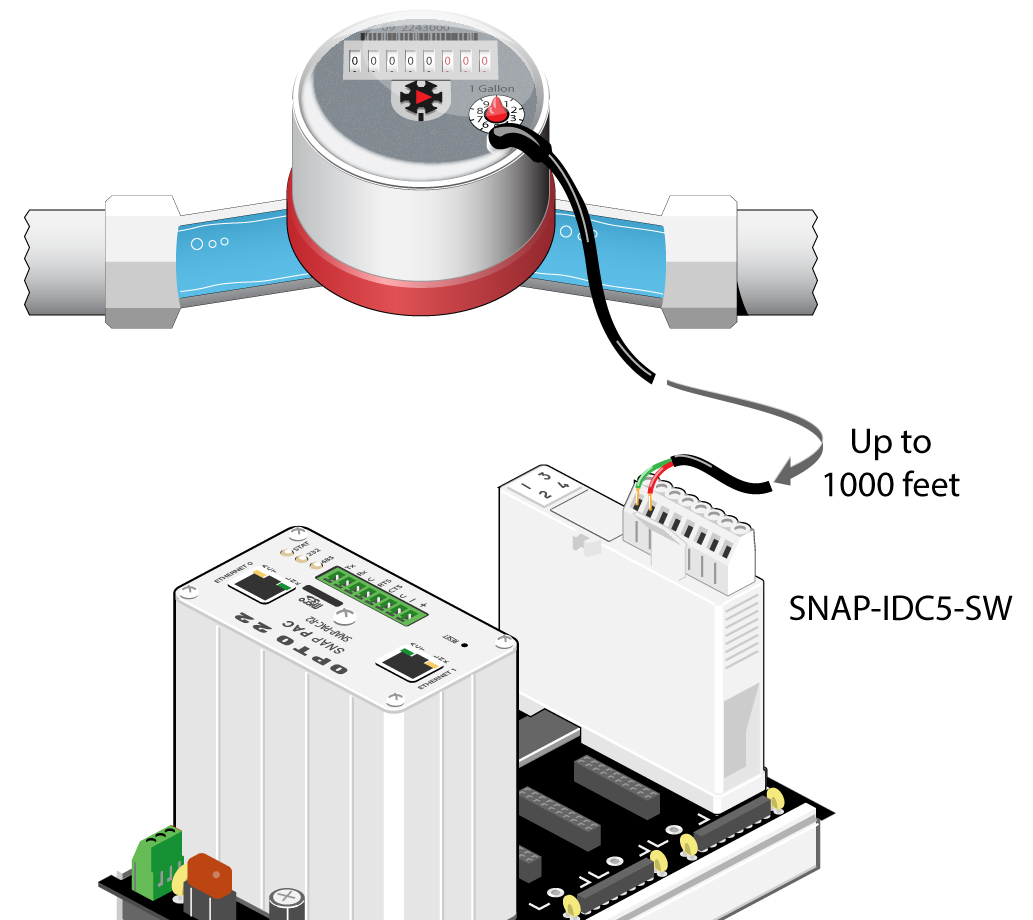

The past few blogs we have talked about visualizing water usage in groov and how it not only helped me save water, but also highlighted the fact that I was not seeing all the water use I thought I was.

Electricity is a bit different from most other things. Spill water on the floor and it's pretty obvious; spill electricity and often no one is the wiser.Was I seeing all the power use in my house? Are there any so-called phantom loads (sometimes called vampire loads) sucking or sipping power that I did not know about?