Our MQTT series continues with a deep dive into groov EPIC’s (and now groov RIO’s) features for high-reliability MQTT networks.

At its heart, MQTT was designed for unreliable networks. Back in the ’90s, ConocoPhillips (now Phillips 66) was looking for a way to improve telemetry reporting over its low-bandwidth dial-up and costly VSAT (small satellite dish) SCADA network. IBM partnered with system integrator Arcom Control Systems (now Cirrus Link Solutions) to develop a minimalist communication protocol that could gracefully handle intermittent network outages and high latency among many distributed devices over TCP/IP.

Read More

Topics:

Node-RED,

MQTT,

Ignition Edge,

groov EPIC,

groov Manage,

Sparkplug,

MQTT implementation,

groov RIO

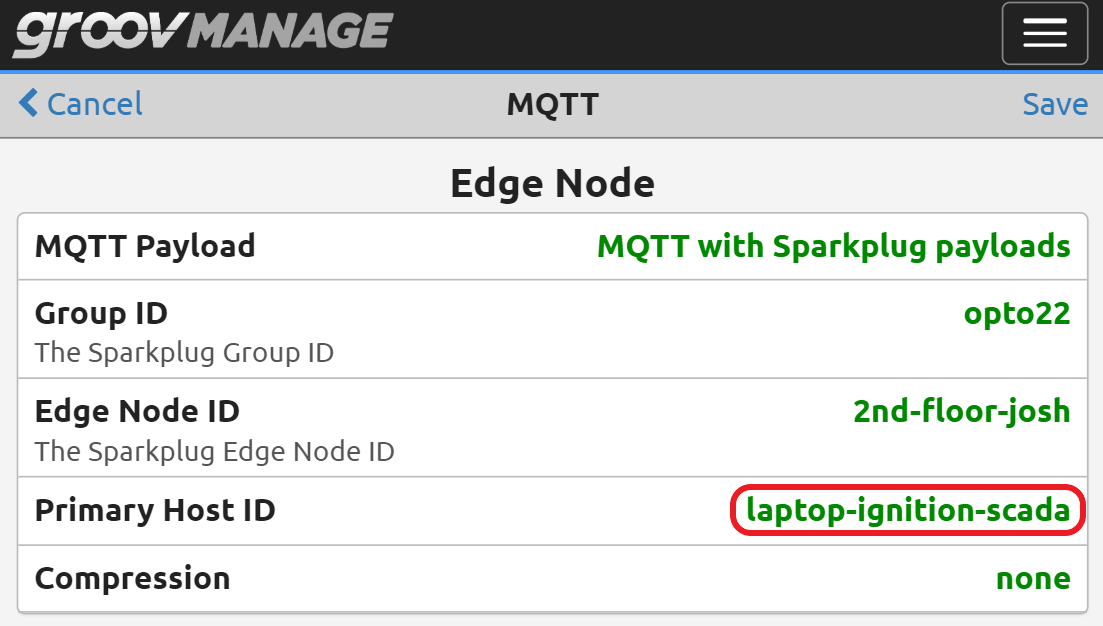

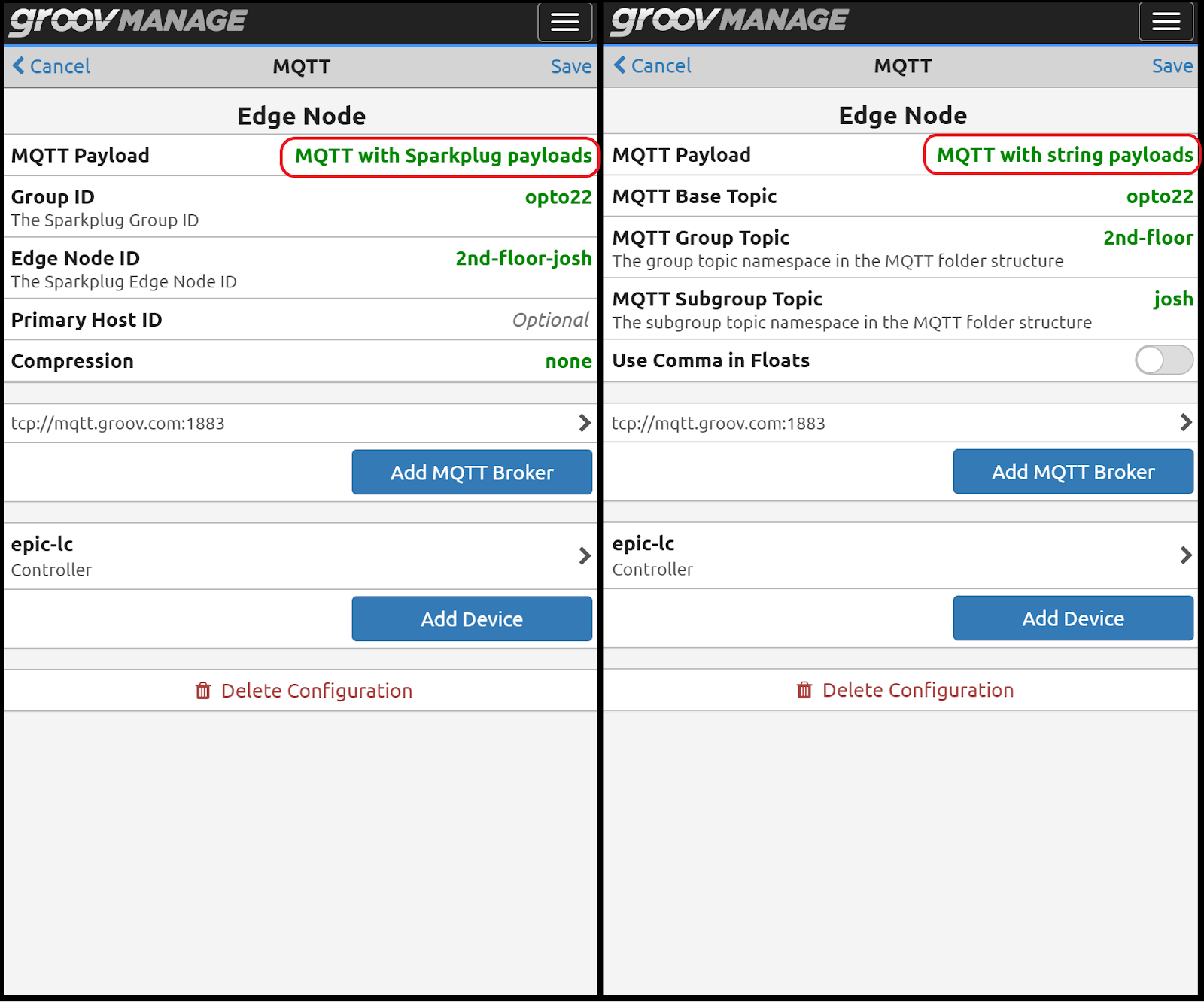

In part 2 of our series, we look at how to set up groov Manage and Ignition Edge for publishing with Sparkplug B payloads.

MQTT is the darling of enterprise IoT because of its efficiency, simplicity, and flexibility, which makes it ideal for use in applications that communicate with resource-constrained edge-of-network devices. After being nurtured for years within IBM, and incorporated into their smart energy, health, and utilities solutions, MQTT has become the chosen messaging protocol across all the major cloud IoT platforms as well as highly scalable applications, like Facebook Messenger.

Read More

Topics:

Node-RED,

MQTT,

Ignition Edge,

groov EPIC,

groov Manage,

Sparkplug,

MQTT implementation

Take advantage of more opportunities to learn about Inductive Automation's Ignition software, part of the groov EPIC system.

Opto 22 will be sponsoring and participating in three Ignition-related events in Orlando in February. If you plan on attending the annual ARC Industry Forum, you'll want to extend your visit that week to include one or more of these Inductive Automation events.

Read More

Topics:

MQTT,

Ignition Edge,

groov EPIC,

Ignition,

Discovery Day

Opto 22 engineers discuss the latest news and happenings from the annual Ignition Community Conference hosted by Inductive Automation.

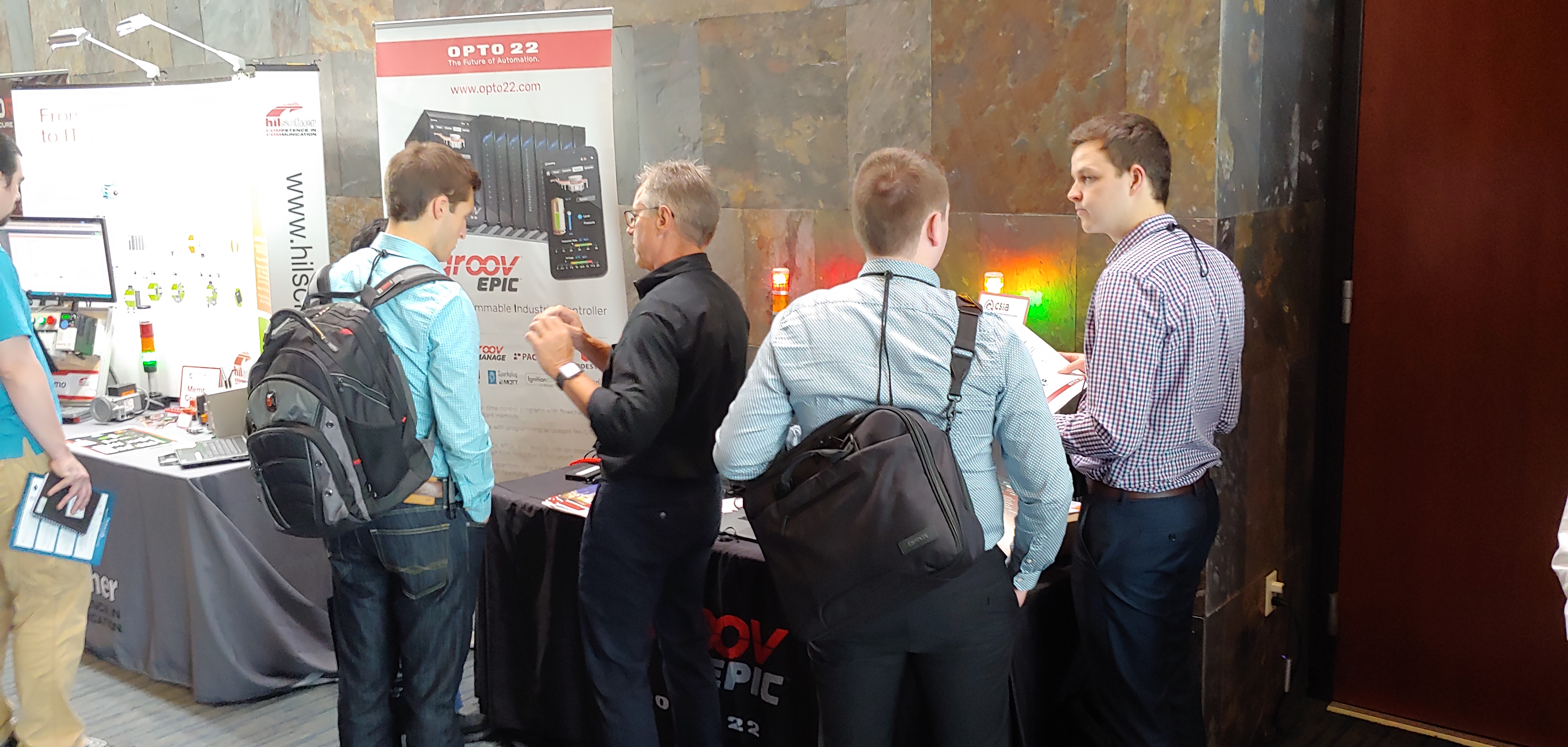

As an Ignition Onboard partner, Opto 22 was once again a part of this year's Ignition Community Conference (ICC). This annual event is a great opportunity for engineers and developers to network, get technical training, and learn from the Ignition software experts. You can meet with other Ignition users who are using this tool every day in all sorts of applications, from all over the world. Whether you're an advanced user or new to the software, you'll leave with a new perspective and set of ideas for your projects.

Opto 22's Senior Applications Engineer, Garrick Reichert, and VP of Marketing & Product Strategy, Benson Hougland were on hand to answer questions about how this Ignition platform is used in the groov EPIC system.

Read More

Topics:

Ignition Edge,

groov EPIC,

Ignition,

ICC,

Ignition Community Conference

Step inside Opto 22 HQ again for day 2 of groov EPIC training.

The Outside-In series brings you an outsider’s perspective into the way Opto 22 operates behind the scenes. Today, we’re back in Temecula, CA (not Australia… I know! I was surprised too) for the next day of groov EPIC® system factory training. If you missed the first day, the class was introduced to groov Manage and PAC Control™. Plus, we got to see Terry Orchard demo Linux® secure shell access on the EPIC.

Day 2 wraps up PAC Control and covers PAC Display™, groov View™, Ignition Edge® and CODESYS®. If you’re interested in the hands-on training available for HMI/SCADA development or IEC 61131-3 languages on the EPIC platform, keep reading.

Read More

Topics:

Training,

IIoT,

Ignition Edge,

PAC Display,

CODESYS,

groov View,

groov EPIC,

groov EPIC Learning Center,

Factory Training

Documenting the journey from the outside world into the world of Opto: First in a series.

After more than a decade as an automation engineer, I recently joined Opto 22’s marketing group. A few weeks ago, my workday was focused on maintaining the cell culture process automation of a world-class pharmaceutical manufacturer. This system had dozens of distributed controllers and hundreds of devices that worked together to deliver thousands of kilograms of the finest monoclonal antibodies you’ve ever seen. It was big.

What I enjoyed most about my job, though, was helping other engineers succeed. In the early years, I learned pretty quickly that you could take a group of smart people, give them bad tools, callous management, and a ridiculous schedule, and they would fail every time. I did the best I could to fix the managerial and scheduling issues, but the tools were always a limitation.

Now it’s my job to help connect other engineers with the kinds of tools and technologies I wish I’d had. I’m kicking it off with a deep-dive into the first place I visited as a new Opto employee: the training room.

If you’re wondering whether it’s worth your time and money to get some Opto training yourself, I’ll be walking through everything you can expect to experience.

Read More

Topics:

Training,

PAC Control,

Node-RED,

Ignition Edge,

groov EPIC,

groov EPIC Learning Center,

Factory Training

Pick from three options to fit your time and budget.

“Tell me and I forget. Teach me and I remember. Involve me and I learn.” — Benjamin Franklin

Read More

Topics:

PAC Control,

IIoT,

Node-RED,

MQTT,

Ignition Edge,

CODESYS,

groov EPIC,

HMI,

groov EPIC Learning Center,

OptoU

The groov EPIC has always come pre-installed with Ignition Edge® by Inductive Automation® on board. Ignition Edge in the EPIC means you have OPC-UA drivers built in to communicate with other control systems (for example, Allen-Bradley and Siemens PLCs). It also means you can use MQTT/Sparkplug for more efficient and secure data communications.

But starting with groov EPIC firmware version 1.4.0 (released in August 2019), that changes—in a good way. You now have the option to choose which edition of Ignition you run on your Edge Programmable Industrial Controller—either Ignition Edge or full Ignition.

Read More

Topics:

Ignition Edge,

groov EPIC

Firmware update 1.4.0 is now available for the groov EPIC processor, GRV-EPIC-PR1.

Our engineering team released an exciting new update for groov EPIC this week. Here are some of the highlights.

Read More

Topics:

Node-RED,

Ignition Edge,

CODESYS,

groov EPIC,

software,

serial module,

OpenVPN