Take advantage of new features, fixes, and improvements in this latest release of the PAC Project software suite, R10.6.

Whether you use Opto 22's basic or professional version of the PAC Project Software Suite, you'll want to hear about some new features and enhancements just added in the latest release.

Let's review the highlights and see what changes you can expect in PAC Control, PAC Manager, and PAC Display.

Read More

Topics:

PAC Project,

PAC Control,

PAC Manager,

PAC Display,

OptoOPCServer,

OptoDataLink

Take advantage of free tools to jumpstart your industrial automation projects.

Whether you're an engineer, technician, or developer, starting a new project can be daunting. But what if you could hit the ground running with resources that streamline your workflow?

Let's explore how you can accelerate your application using a suite of free tools designed to simplify and expedite your development process.

Read More

Topics:

PAC Control,

Node-RED,

CODESYS,

groov EPIC,

developer,

Ignition,

groov RIO,

python

Laundry OEM Gurtler Industries reinvents their dispensing systems with groov EPIC and Opto 22's free Software Development Kits (SDKs).

What do you do when competitors in the chemical storage and dispensing industry are surpassing you, and a shift in technology is needed to put you back at the forefront of laundry operations?

Learn how Gurtler Industries, a third-generation family business based in the United States Midwest, regained its position as a leading provider of laundry chemical products, services, and support for many industries including healthcare, hospitality, and textile rentals. When their competitors began leveraging data collection, remote monitoring, and enhanced visualizations, Gurtler knew they also needed to expand the capabilities of their dispensing systems to maintain their competitive market position.

In this case study, find out how Gurtler Industries was able to stay ahead of the competition by transitioning to an open-source platform with Opto 22's free Software Development Kits (SDKs) and advanced hardware solutions.

Read More

Topics:

Case studies,

OEM,

PAC Control,

groov EPIC,

sdk

Understanding different data types in your PAC Control programming.

You don’t need to have the title "software engineer" on your business card before you code up your first automation process. In fact, I suspect that many industrial automation folks are like me—self-taught and come from the school of hard knocks.

This blog post is more of a musing out loud than a "you must" edict. Programming, after all, is often more art than science.

Read More

Topics:

PAC Control,

technical tips

Some tech tip advice to help keep your industrial systems running smoothly.

Whenever I say this blog title out loud to the Premium Factory Training class attendees, I get some funny looks. I'm not sure if it's the Aussie accent, or the idea of adding delays to speed up that causes the double-take chuckles.

Compute power has come a long way in the last 10 years or so, but regardless, we programmers of all things industrial still need to be mindful of optimizing our code and systems to run as smoothly as they possibly can.

Arguably, one of the biggest tips for programming in PAC Control I can share with you all is to add delays through your flow charts and OptoScript blocks.

Read More

Topics:

PAC Control,

groov EPIC,

Factory Training,

technical tips

Week 6 of the groov Manage video series brings you a detailed look at the control engines included with groov EPIC.

You might think we have a sleeper menu feature for this week's blog: only two buttons behind the Controller groov Manage menu option. Boring, right? Far from it! This is amazing!

The fact that you can even choose between two control engine options is worth a pause. Learn what's possible in this week's groov Manage: Controller video.

Read More

Topics:

PAC Control,

CODESYS,

groov EPIC,

groov Manage,

groov Manage series

Using powerful built-in software, it’s easy to add more functionality to the multifunction, mixed signal I/O on groov RIO, including using RTD temperature probes with minimal code.

The groov RIO MM1, MM2, and even the groov EPIC GRV-MM1001-10 modules are extremely flexible, with an incredible number of software configurable options. Even with all that potential, you can do more when you combine this I/O with software tools like PAC Control, CODESYS, Node-RED, and custom Linux programs.

A great way to see this is with RTD sensors.

Read More

Topics:

PAC Control,

Node-RED,

CODESYS,

groov RIO,

temperature sensor,

RTD

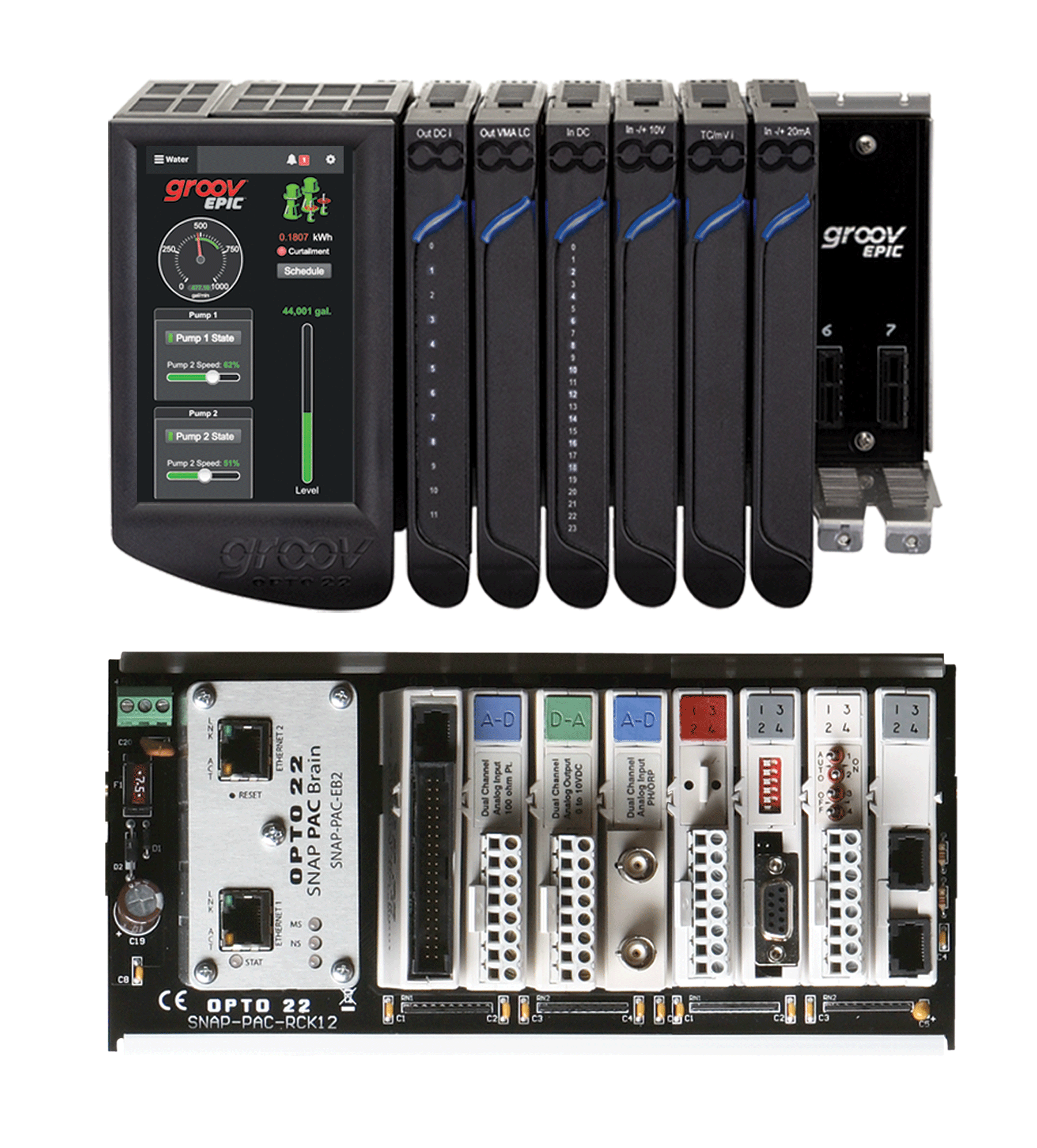

Honest answers to your questions about making the move from SNAP PAC controllers to groov EPIC.

I’d like to try and feed two birds with one handful of grain in this blog…

We often get these two questions from existing Opto 22 customers who are moving or migrating from SNAP PAC controllers to groov EPIC (or sometimes keeping SNAP I/O to work with an EPIC system).

- Are they the same?

- Which should I configure first, groov Manage or PAC Control?

Read More

Topics:

PAC Control,

groov EPIC,

snap pac

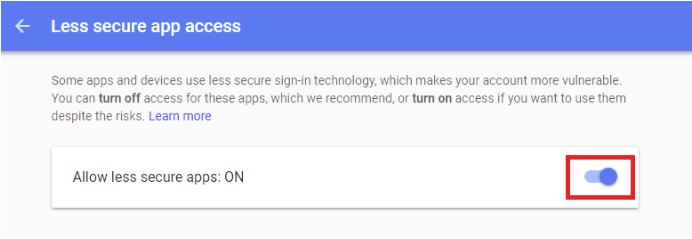

New technical note shows you how to update security settings for your email applications.

You can use many Opto 22 products to send email notifications to keep engineers and technicians aware of important conditions in your system. For example:

- You can send email through a PAC Control strategy running on a groov EPIC or SNAP PAC controller.

- Your groov View HMI can send event notifications via email.

- Your Node-RED flow on groov RIO or groov EPIC can send email.

But you must make changes now to keep receiving emails!

Read More

Topics:

PAC Control,

Node-RED,

groov View,

groov EPIC,

snap pac,

groov RIO,

email notifications

A recent firmware release provides important updates for groov RIO MM1 and MM2 devices.

Keep your groov RIO edge I/O module up to speed with the latest firmware updates and fixes. The recently released groov RIO firmware version 3.3.1 is now available. Here are some reasons you'll want to update.

Read More

Topics:

Firmware,

PAC Control,

groov RIO