Dan White

Dan has worked at Opto 22 for more than a decade. His Tufts Engineering background, MBA in International Business, and prior industrial controls experience give him a unique edge in automation. Dan enjoys staying active through biking, basketball, skiing – and keeping up with his three young kids!

Why a first-of-its-kind event is changing the world of SCADA.

Attending the inaugural OT SCADA CON in Houston can only be described as “a breath of fresh air.” I attend a lot of automation industry events, and this one was a hit—thanks in large part to its excellent format.

Informative sessions were kept to 30 minutes—a block of time long enough to highlight each speaker’s real-world experience and expertise, but short enough to keep the audience engaged, attentive, and in some cases, QUITE entertained.

Read More

Topics:

Events & conferences,

IIoT,

SCADA,

OT data

In 1974, Robert Engman III stared down at 22 optically isolated, highly reliable, liquid epoxy-filled, solid state relays (SSRs) with no moving parts—quite an innovation back then—and he contemplated what to name the new company.

The result? "Opto" signifies optical isolation, and the "22" represents the original lineup of 22 relays. But this year, there’s another important number that we need to discuss—50!

Yes, Opto 22 is 50. Years. Young.

This week, as we celebrate Opto’s Golden Anniversary of existence, I’d be remiss not to reflect on the legacy of a company I have loved being a part of for the last decade. And while my 11 years may seem like a long time, many of the folks I work with each day have tenures twice or thrice as long—they’ve been carrying the torch, maintaining the legacy that we are still building today.

Read More

Topics:

groov EPIC,

snap pac,

groov RIO,

Anniversary

Were you in Chicago for Automate 2024? Dan White shares some highlights from last week's show.

As cities worldwide buzz back to life post-pandemic, trade shows are reclaiming their spotlight, and none more so than the recent Automate Show held in Chicago. With over 800 exhibitors showcasing the latest in automation and robotics tech, the McCormick Place was the place to be.

Read More

Topics:

Events & conferences,

groov EPIC,

Ignition,

groov RIO,

Inductive Automation

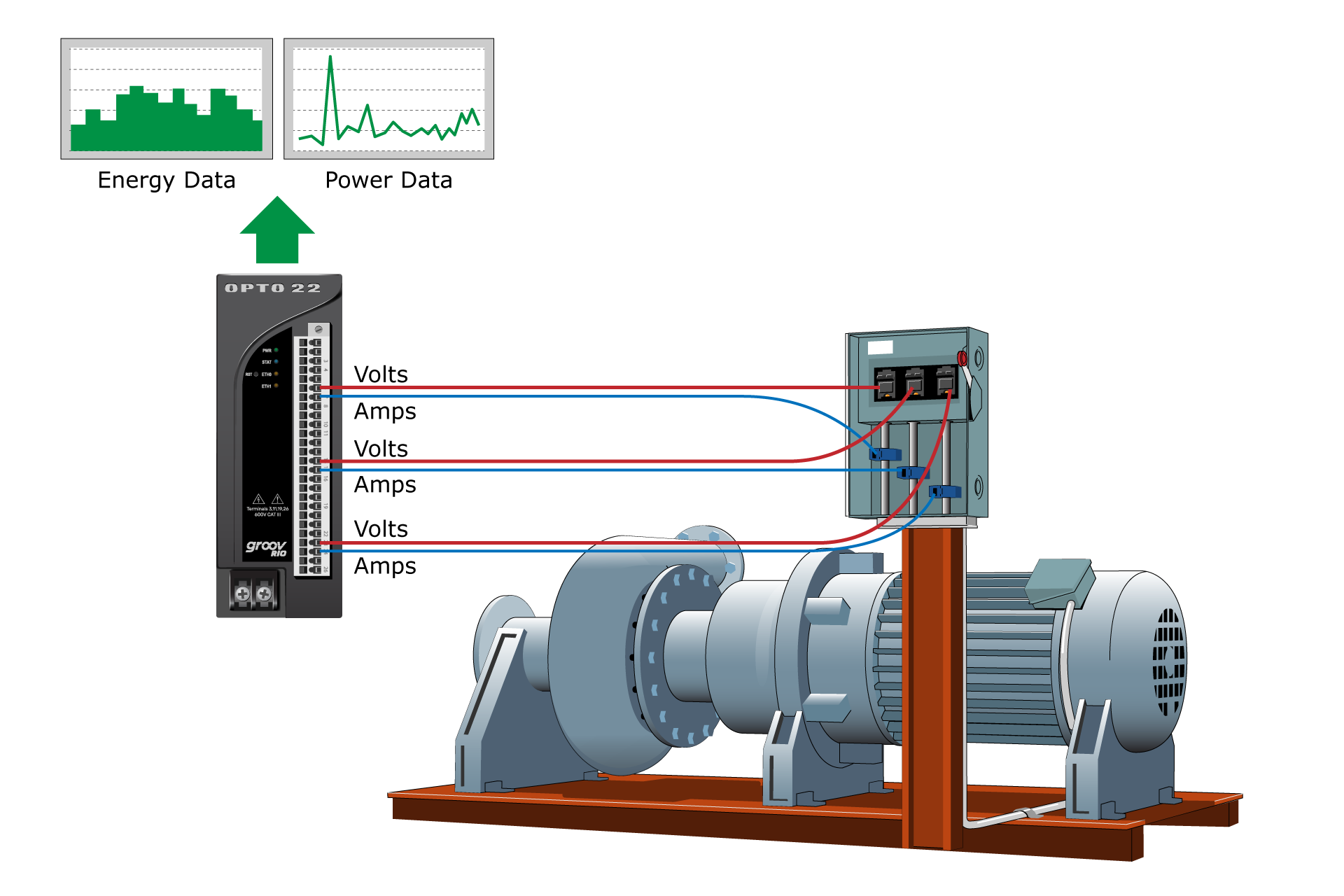

Start analyzing your energy data to manage and reduce your energy consumption.

Managing and reducing your energy consumption sounds like a no-brainer. Save thousands on electricity, maintain critical machine health, reduce carbon footprint? Sign me up!

Where to begin? Well, the best place to start is analyzing your energy data, but unfortunately, you can’t find that data on your electric bill—it’s barely a summary. To manage your energy, start by measuring it. Once you determine where, when, and how that energy is consumed, areas for improvement become obvious.

Read More

Topics:

Energy management,

groov rio emu,

energy monitoring

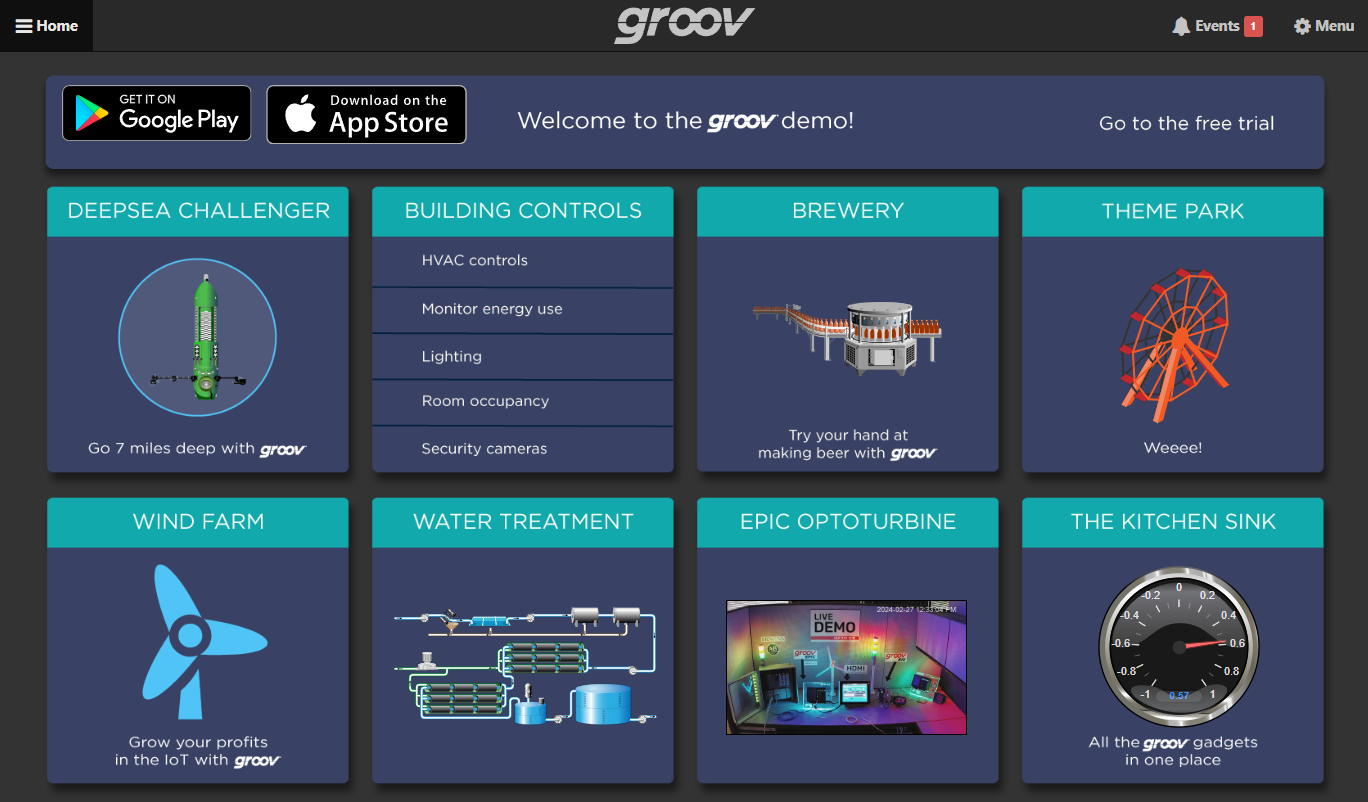

Visit Opto 22's two product demo sites for a hands-on learning experience.

I know, you're always on the hunt for tools that make your life easier and your projects cooler, and I've got something you might want to check out—interactive demos for groov View and Ignition Cloud Edition.

This is a chance to dive into what these platforms can really do for your visualization and overall SCADA needs. If you’re already familiar with Opto 22 products, you’ve probably heard of groov View—an intuitive, web-based HMI/visualization software that comes standard on every groov EPIC. You may not have heard of Inductive Automation’s Ignition—a versatile industrial application platform for SCADA, MES, IIoT projects, and more.

Read More

Topics:

groov View,

groov EPIC,

interactive demo,

Ignition Cloud Edition

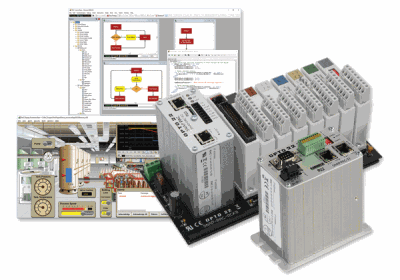

You can feel secure in your SNAP PAC product designs.

In the ever-evolving industrial automation industry, it's crucial to have a solid foundation you can rely on. For many of you, that foundation has been built on our SNAP PAC systems, and you’ve grown accustomed to the reliability these systems provide your automation projects. We understand the importance of SNAP PAC in your operations, and we're here to reassure you: your trust in Opto 22 SNAP PAC controllers and I/O modules is well placed, now and into the future.

At Opto 22, we know that designs and projects that incorporate SNAP PAC are more than just configurations of hardware and software; they are the lifeblood of your operations, which is why we are committed to ensuring that you can feel secure in your designs for the long haul.

Read More

Topics:

snap pac,

Opto 22 product support,

product design

Opto 22's Director of Technical Marketing, Dan White, shares his experience from this year's annual ARC event.

In its 28th year, the ARC’s Industry Forum did not disappoint. I just returned from this cutting-edge event where tech enthusiasts and industry professionals gathered to explore the latest in smart manufacturing, digital transformation, and industrial automation, and I’m eager to share the highlights and heartbeats of this remarkable gathering.

Read More

Topics:

Events & conferences,

groov EPIC,

ARC Forum,

industrial automation,

digital transformation,

smart manufacturing

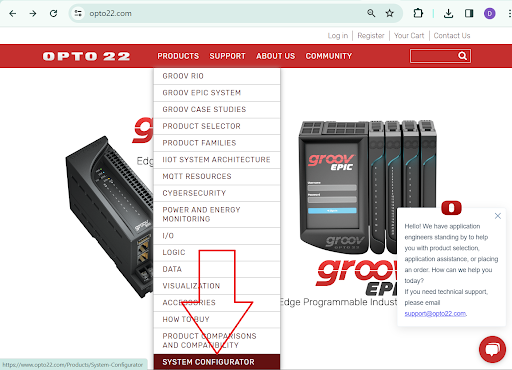

These website tools make it easy to design your automation systems and choose the parts you need.

Hey Opto crew! Today, I want to walk you through something pretty cool and super useful – our System Configurators at Opto 22. These tools are all about making your life easier when it comes to picking the right automation gear. No fluff, just the good stuff, including all the specs for the parts you'll need, and you can access them all from the Products section of our website.

Read More

Topics:

groov EPIC,

snap pac,

groov RIO

The Eclipse Foundation recently announced the Sparkplug international standard achievement.

Sparkplug, the MQTT specification that enhances the way your Opto 22 groov systems communicate and operate, has achieved the ISO/IEC 20237:2023 International Standard Status. It’s a significant milestone in the IIoT world, particularly for Opto 22 and our users. As you know, Opto 22 adopted Sparkplug years ago because of its reliability, efficiency, and plug-and-play functionality in modern IIoT architectures. It’s nice to see the rest of the industry accepting and adopting this groundbreaking tech.

Read More

Topics:

MQTT,

groov EPIC,

Sparkplug,

groov RIO,

Eclipse Foundation

Learn the different options available to you for free product support from Opto 22.

You deserve support that's as reliable and efficient as the automation solutions you implement. At Opto 22, we stand by this principle by offering you free, unlimited technical support, a token of our gratitude for your business and trust. Unlike other automation companies that charge a fee for support, we ensure that you have access to expert help in any form you need it, at no extra cost—because your success is our success. Here's how we make good on that promise.

Read More

Topics:

groov EPIC,

groov RIO,

Opto 22 product support

.png)

-3.jpg)