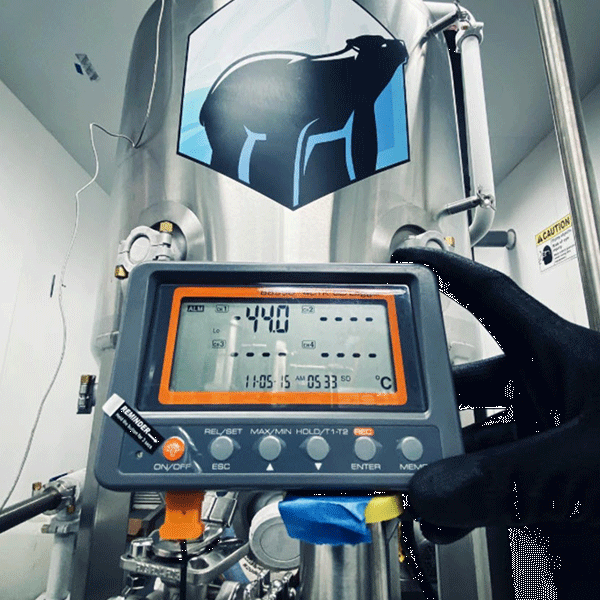

Learn from PermaCool's experience of scaling custom chillers with smarter automation and remote diagnostics.

Are you dealing with the challenges that come with a third-party or outsourced controls system?

What happens when you need to troubleshoot or make a repair, but you don't have access to the controls?

PermaCool, a busy OEM in the plant extraction industry, encountered a bottleneck when its outsourced components couldn't keep pace. Read this new case study to see how they overcame the limitations they faced and were able to push the boundaries of what they could accomplish.

Read More

Topics:

Case studies,

OEM,

groov EPIC

Check out this new website resource to learn how groov products help you build better machines.

As an Original Equipment Manufacturer (OEM), what sets you apart in your industry? How can you provide more value to your customers?

Opto 22 groov products are designed with OEM machine builders in mind. That's why you'll want to check out this new website resource dedicated to OEMs. It shows how you can:

- Stand out with your customers

- Reduce initial costs

- Reduce ongoing costs

Learn how to build better machines and get the technical support you're counting on.

Read More

Topics:

Machine builder,

OEM,

groov EPIC,

groov RIO

Learn from this new case study as CryoPhit USA explains how they overcame the complexity of cryotherapy systems with an advanced automated solution.

CryoPhit USA needed to design a system that was easy to use, maintain, and service, ensuring accessibility for end users, operators, and refrigeration technicians. This meant access to real-time data would be key. Sound familiar?

In this case study, find out how the groov RIO provided real-time data, predictive diagnostics, and remote access for their innovative cryochambers.

Read More

Topics:

Case studies,

OEM,

groov RIO

Laundry OEM Gurtler Industries reinvents their dispensing systems with groov EPIC and Opto 22's free Software Development Kits (SDKs).

What do you do when competitors in the chemical storage and dispensing industry are surpassing you, and a shift in technology is needed to put you back at the forefront of laundry operations?

Learn how Gurtler Industries, a third-generation family business based in the United States Midwest, regained its position as a leading provider of laundry chemical products, services, and support for many industries including healthcare, hospitality, and textile rentals. When their competitors began leveraging data collection, remote monitoring, and enhanced visualizations, Gurtler knew they also needed to expand the capabilities of their dispensing systems to maintain their competitive market position.

In this case study, find out how Gurtler Industries was able to stay ahead of the competition by transitioning to an open-source platform with Opto 22's free Software Development Kits (SDKs) and advanced hardware solutions.

Read More

Topics:

Case studies,

OEM,

PAC Control,

groov EPIC,

sdk

Mercer Technologies continues to innovate—adding energy cost per part.

Are you considering ways to include energy monitoring in your industrial applications? Now you can hear first hand how long-time Opto customer Mercer Technologies is making it happen.

The latest case study in the groov case study library features Mercer Technologies' story of innovation. See how they leverage energy monitoring data from Opto 22's groov product family.

Read More

Topics:

Case studies,

OEM,

groov EPIC,

groov rio emu,

energy monitoring

Oil & Gas OEM uses integrated data and control to deliver reliable automated pressure testing

Engenuity, Inc. provides control automation and data integration solutions across several industries, with a primary focus on advanced technologies for oil & gas. You've probably seen their OptoPartner profile featured here before.

In a new case study, we dig into the details of how they use groov EPIC to design an automated solution that cuts the cost of validated pressure testing at remote well sites.

Read More

Topics:

Case studies,

OEM,

Oil & gas,

groov EPIC,

OptoPartner

groov RIO enables affordable equipment-as-a-service designs that are easy to deploy

Download case study pdf

Equipment-as-a-service (EaaS) involves renting out or providing access to equipment and collecting payment periodically, rather than selling the equipment outright. This payment model enables end users to pay for costly or infrequently used equipment as an ongoing operating expense, which can open new markets for machine builders.

Read More

Topics:

OEM,

Node-RED,

groov RIO,

EaaS

A new kind of industrial controller simplifies and secures automation and IIoT projects, while reducing cost and complexity.

We've recently published a new white paper that explains why and how Edge Programmable Industrial Controllers (EPICs) are the solution for today's–and tomorrow's–automation applications.

For today's controls engineers, new demands to use and share data present three main challenges: security, complexity, and expense.

Read More

Topics:

OEM,

IIoT,

Industrial Internet of Things,

EPIC,

groov EPIC,

white paper

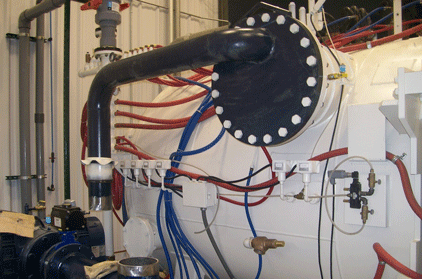

FCI Watermakers improves large-scale seawater reverse osmosis system design with groov EPIC.

Question: What do a yacht owner, an island resort, and a Las Vegas chef have in common?

Answer: They all need a reliable source of good fresh water—and they all count on FCI Watermakers to

provide it.

Read More

Topics:

Water & wastewater,

OEM,

IIoT,

EPIC,

groov EPIC,

reverse osmosis

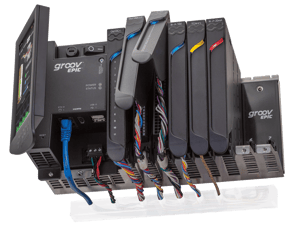

Would you like to know more about the new groov EPIC system?

Now you can, on your own schedule.

- Learn how to simplify your automation and IIoT projects.

- See how to improve security and performance, with minimal reliance on IT personnel.

Read More

Topics:

Webinars,

groov,

Internet of Things,

IoT,

Machine builder,

OEM,

New products,

Integrators,

Security,

IIoT,

Industrial Internet of Things,

Data acquisition,

EPIC

.png)