Maybe you're monitoring temperature, or controlling a production line, or getting data from a load cell. Whatever your goal, you want to get the I/O that works best for your application.

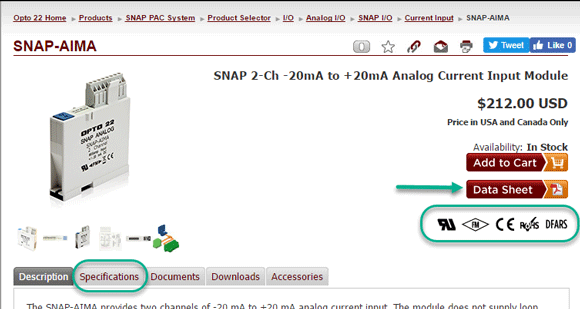

Or maybe you happen to notice we have more than one SNAP-AIV voltage input module and wonder how they're different.

Here are a couple of ways to find a SNAP module with the features you need and compare similar modules.

Read More

Topics:

Energy management,

Process control,

Discrete control,

Tips,

Machine builder,

optonews,

OEM,

Integrators,

I/O,

Data acquisition

It's easy to get confused between Opto 22 SNAP PAC controllers and SNAP PAC brains.

They're both intelligent processors for automation, some of them look alike, and there's even overlap in what some of them do.

Let's take a look at how SNAP PAC controllers and brains are similar and how they're different.

Read More

Topics:

Tips,

PACs,

I/O,

API,

REST API

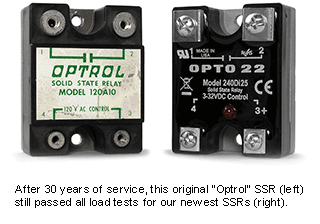

Over 40 years ago, Opto 22 started manufacturing solid state relays (SSRs). With the wide variety we've built over the years, we probably have the SSR you need in stock right now.

We also have some advice on choosing and running SSRs in specific applications.

Read More

Topics:

Tips,

SSRs

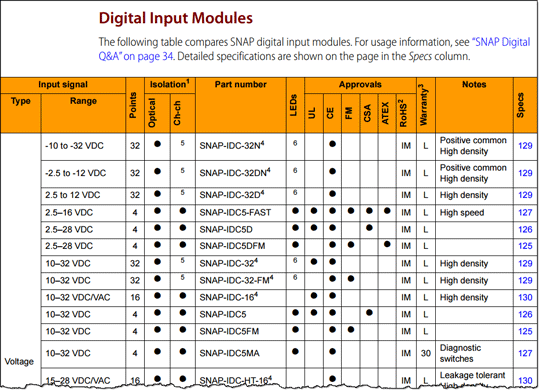

Suppose you're spec'ing a system and you know that one location will require Factory Mutual-approved I/O. Which Opto 22 SNAP I/O modules have FM approval?

Or suppose the products you purchase must be UL approved, or meet certain European Union (CE) standards.

What if you just want to know what the warranty period is for a specific Opto 22 part?

Read More

Topics:

Process control,

Discrete control,

Tips,

Machine builder,

optonews,

OEM,

Integrators

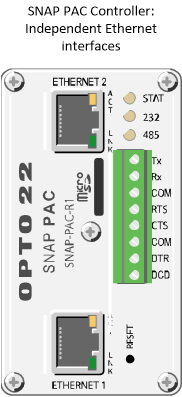

Opto 22 SNAP PAC controllers and brains both have two Ethernet network interfaces—pretty handy. But do you use them the same way? That's the question we'll answer in this tech tip.

Most devices used on an Ethernet network have one network interface with an RJ-45 connector. But SNAP PAC controllers and EB brains each have two interfaces—two RJ-45 connectors.

However, the two interfaces on controllers and brains are designed for different uses.

Read More

Topics:

Tips,

optonews,

PACs,

Networking,

OptoNews 2017-04-12

One Ethernet network troubleshooting tool our Product Support Group recommends is Wireshark. It's been a helpful choice for many years, and it's free.

Our recent blog post explains where to get Wireshark and how to use it. You can pay a lot for network analysis tools—and in some cases you may need them—but many times, the free ones do the job.

Read More

Topics:

Tips,

optonews,

Networking,

OptoNews 2017-03-29

When you're working on your network, what's in your toolkit?

For automation networks or IT computer networks, a few essential cables and adapters should be in your kit.

That way you've got them handy, whether you're troubleshooting network problems or just keeping your equipment and line up and running.

Read More

Topics:

Tips,

optonews,

Integrators,

Networking,

OptoNews 2017-03-15

Two of our software development kits (SDKs) have just been updated to provide support for Microsoft® Windows® 10 Professional, 8.1 Professional, and 7 Professional, both 32-bit and 64-bit.

The PC-Based Direct I/O SDK for PCI Adapter Cards is for direct, high-speed control of digital I/O points.

Read More

Topics:

Discrete control,

Updates,

Tips,

Machine builder,

optonews,

OEM,

I/O,

OptoNews 2017-03-01,

Pamux

In a recent developer survey conducted by the Eclipse IoT Working Group, IEEE IoT, and Agile IoT, 40.8% of respondents indicated the Internet of Things (IoT) solutions they were either currently building or planning to build were IoT platforms or IoT middleware.

Almost every large IT or OT company today has some form of IoT platform or middleware, with the current number of self-described IoT platforms exceeding 150.

Read More

Topics:

groov,

Remote monitoring,

Tips,

IoT,

Networking,

IIoT,

Node-RED,

Data acquisition

Process Control

Process control systems are used in everything from advanced manufacturing to run-of-the-mill activities at home, like heating your house and brewing your beer. (You do brew your own beer, don't you?)

A control system that manufactures a product requires monitoring and control of many different process variables, while some at home require little more than a timer. For example, in manufacturing we may use flow meters to make sure fluids flow through pipes at a certain rate, or float meters to ensure ingredients fill a vat to a specified level.

When I brew beer at home, I may use a temperature sensor in my mash tun, wired to a controller that’s controlling my heating element to keep the mash tun at just the right temperature for optimum starch-to-sugar conversion. This is an example of a closed-loop control system.

(To see how small closed-loop control principles are scaled up to build industrial process control applications, check out the New Belgium Brewery case study and see how they use Opto 22 gear to brew their world-famous Fat Tire and other beers.)

Read More

Topics:

Food & beverage,

PLCs,

Tips,

PACs,

Oil & gas