Several of the groov EPIC I/O modules have new firmware updates available.

If you're using the groov EPIC system, you'll want to check the list of groov I/O modules that have new versions of firmware available now. These firmware updates contain both enhancements and bug fixes and are available for download on the Opto 22 website.

Read More

Topics:

Updates,

Firmware,

groov EPIC,

I/O

OptoPartner Advanced Control Solutions is co-hosting a virtual automation event.

Is your organization struggling with your automation solution decisions?

Then join OptoPartner ACS, Olympus Controls, and Gibson Engineering for the Applied Automation Virtual Solutions Day.

Read More

Topics:

Events & conferences,

IIoT,

groov EPIC,

OptoPartner,

groov RIO

New recorded webinar shows how easy it is to connect field assets to the cloud using HiveMQ and then visualize the real-time data in Canary Cloud.

Did you miss this week's webinar with our Tech Partners HiveMQ and Canary Labs? It's now available for on-demand viewing and you might even want to watch it again to catch all the details of the live demo!

Read More

Topics:

Webinars,

MQTT,

groov EPIC,

Sparkplug,

groov RIO,

Technology Partners

Opto 22 recently announced it has joined the Eclipse Foundation—the Sparkplug governing body and industry collective.

As an industrial automation and internet of things (IIoT) manufacturer, Opto 22 is dedicated to educating and influencing the direction of the MQTT IoT protocol. It's an important part of the product strategy behind our groov EPIC and groov RIO product solutions. Therefore, it was a logical step to join the Eclipse open-source software community to foster further collaboration and innovation around the MQTT and Sparkplug standards.

Read More

Topics:

MQTT,

groov EPIC,

Sparkplug,

developer,

groov RIO,

Inductive Automation,

Cirrus Link Solutions,

Eclipse Foundation

Experienced S.I. harnesses the power of Opto 22’s control system.

One thing is for sure -- RDI Controls knows turbine and governor control systems. That said, if you are looking for an experienced Opto 22 systems integrator that can tackle most any application, have a look at our latest OptoPartner video.

Read More

Topics:

PLCs,

PAC Control,

PID loop control,

groov EPIC,

industrial automation,

snap pac,

OptoPartner,

OptoPartner video

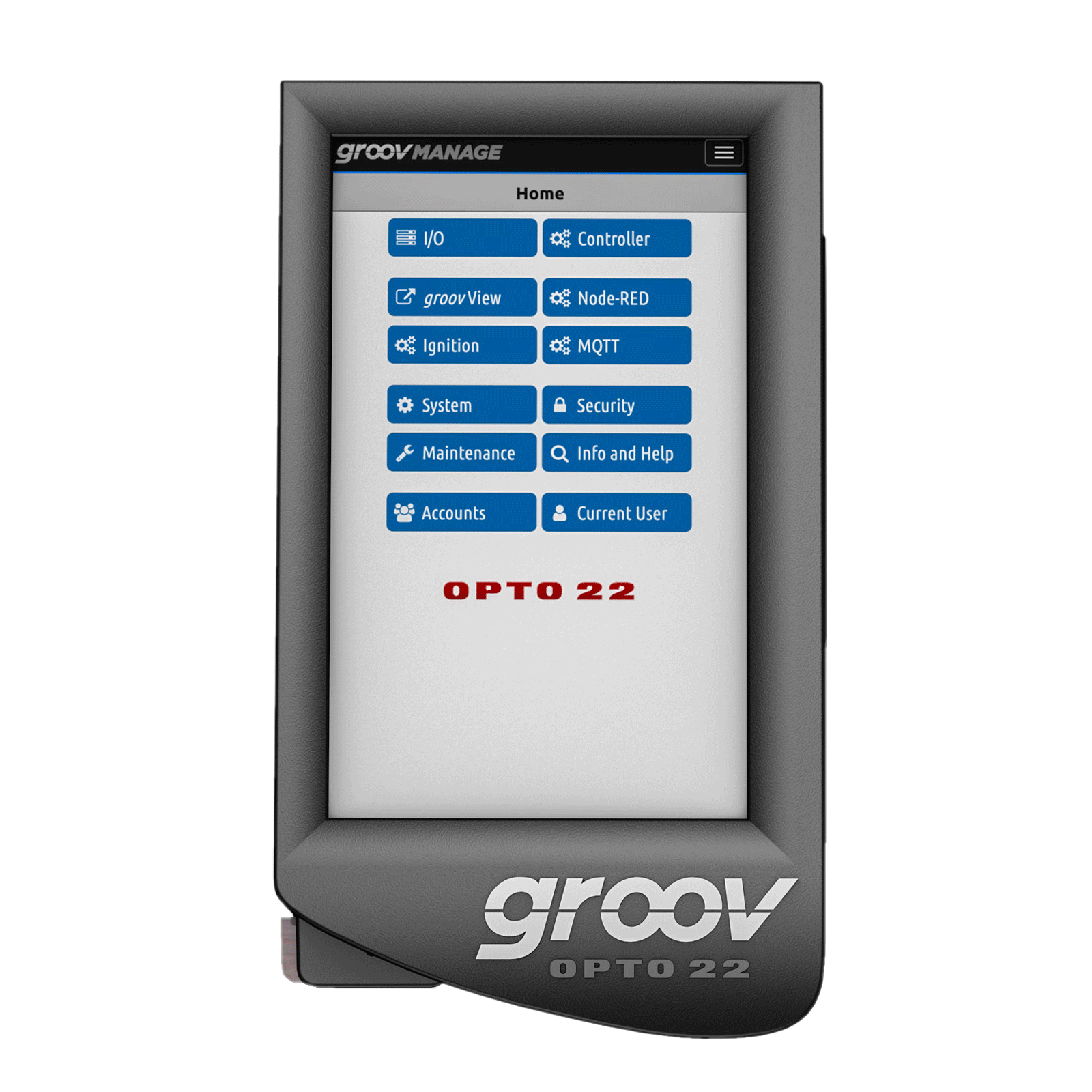

There's a mix of totally new features and improvements to existing software in this new groov EPIC 3.2 firmware release

It just gets better and better. Every new release is just a blast to write about, and I'm here to tell you about all the cool stuff in the latest EPIC 3.2 firmware update.

Read More

Topics:

Firmware,

PAC Control,

MQTT,

groov EPIC,

Ignition

Announcing a second processor model for Opto 22's groov EPIC system.

We have a lot of exciting product news to share, and at the top of that list is the release of the GRV-EPIC-PR2. Yes, you now have two processor options when designing a groov EPIC system! Both GRV-EPIC-PR1 and GRV-EPIC-PR2 provide a powerful, open software and hardware ecosystem for automation and IIoT but with the following important differences:

Read More

Topics:

New products,

groov EPIC,

Ignition

Oil & Gas OEM uses integrated data and control to deliver reliable automated pressure testing

Engenuity, Inc. provides control automation and data integration solutions across several industries, with a primary focus on advanced technologies for oil & gas. You've probably seen their OptoPartner profile featured here before.

In a new case study, we dig into the details of how they use groov EPIC to design an automated solution that cuts the cost of validated pressure testing at remote well sites.

Read More

Topics:

Case studies,

OEM,

Oil & gas,

groov EPIC,

OptoPartner

Join Opto 22 for another webinar hosted by HiveMQ to see the powerful yet simple MQTT technology in action.

Here is another virtual event to add to your calendar. Don't miss an all-new webinar: Connecting a Smart Factory to the Cloud with MQTT & Sparkplug.

Read More

Topics:

Webinars,

MQTT,

groov EPIC,

Sparkplug,

groov RIO,

Technology Partners

Industrial automation hub brings the real-world into the classroom for students

Though I have the highest regard for the university where I received my engineering degree, I felt the curriculum was more theoretical than practical. I was steeped in differential equations and engineering mathematics and didn’t actually have a design project or build anything until my senior year.

Read More

Topics:

Case studies,

Videos,

groov EPIC,

industrial automation,

Ignition,

system integrator,

groov RIO,

digital transformation,

Inductive Automation