New technical note shows you how to update security settings for your email applications.

You can use many Opto 22 products to send email notifications to keep engineers and technicians aware of important conditions in your system. For example:

- You can send email through a PAC Control strategy running on a groov EPIC or SNAP PAC controller.

- Your groov View HMI can send event notifications via email.

- Your Node-RED flow on groov RIO or groov EPIC can send email.

But you must make changes now to keep receiving emails!

Read More

Topics:

PAC Control,

Node-RED,

groov View,

groov EPIC,

snap pac,

groov RIO,

email notifications

groov EPIC becomes a Modbus master/client with a few easy lessons.

With Modbus continuing to be a popular protocol for industrial devices, the chances are pretty good you will need to write a program to communicate with Modbus slave/server devices more than a few times. The groov EPIC controller offers several Modbus communication options, and CODESYS, an IEC 61131-3 compliant development environment, is one of them.

With your PLC programming experience and the Using groov EPIC as a Modbus Master in CODESYS course on OptoU, creating a CODESYS project with Modbus master functions will be a breeze.

Read More

Topics:

Training,

Modbus,

CODESYS,

groov EPIC,

OptoU

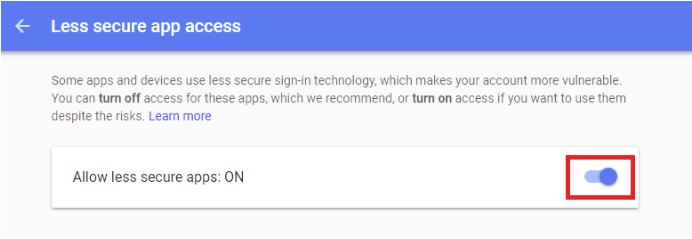

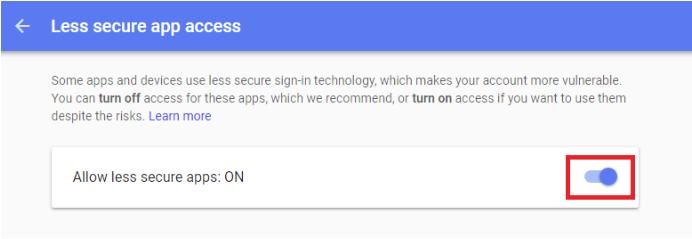

Prepare to make security changes to your email accounts by May 30, 2022.

For a long time, automation engineers have sent email alerts and reports from automation applications via a ‘throwaway’ Gmail account. This seemed harmless enough at the time and really useful, but it wasn’t very secure. As email abuse has risen over the years, it's time for the “less secure” party to come to an end.

Does this mean an end to all email alerts? Not at all. You just need to adjust your Google Gmail settings and update to a new application password in each application. Of course, this applies (with different end dates) to most other email providers as well as Google; check with your email provider for details. This blog will focus on Google Gmail.

Read More

Topics:

Security,

Node-RED,

groov EPIC,

snap pac,

groov RIO,

email notifications

Take part in a new virtual workshop that brings together changemakers in automation.

IntegrateLive! is a new collaboration that aligns integrators, vendors, and end users that share these values:

OPEN: Dedicated to making data flow freely between solutions and willing to work with others, even when they are competitors.

SERVICE: Fair business practices, publicly available pricing, and clear communication about what works and what doesn't.

HUMBLE: Not believing we have all the answers. Together we are better. Striving to learn from others and serve others at the same time.

The end result? An integrated solution ecosystem that you can use to solve everyday industrial problems.

Opto 22 is excited to be a part of this open collaboration and invites you to witness live demonstrations of different vendors' technologies working together.

This post has been updated since it's original publication date. The IntegrateLive! workshop recording is now available for on-demand viewing. Watch now.

Read More

Topics:

Events & conferences,

groov EPIC,

cybersecurity,

groov RIO,

open source

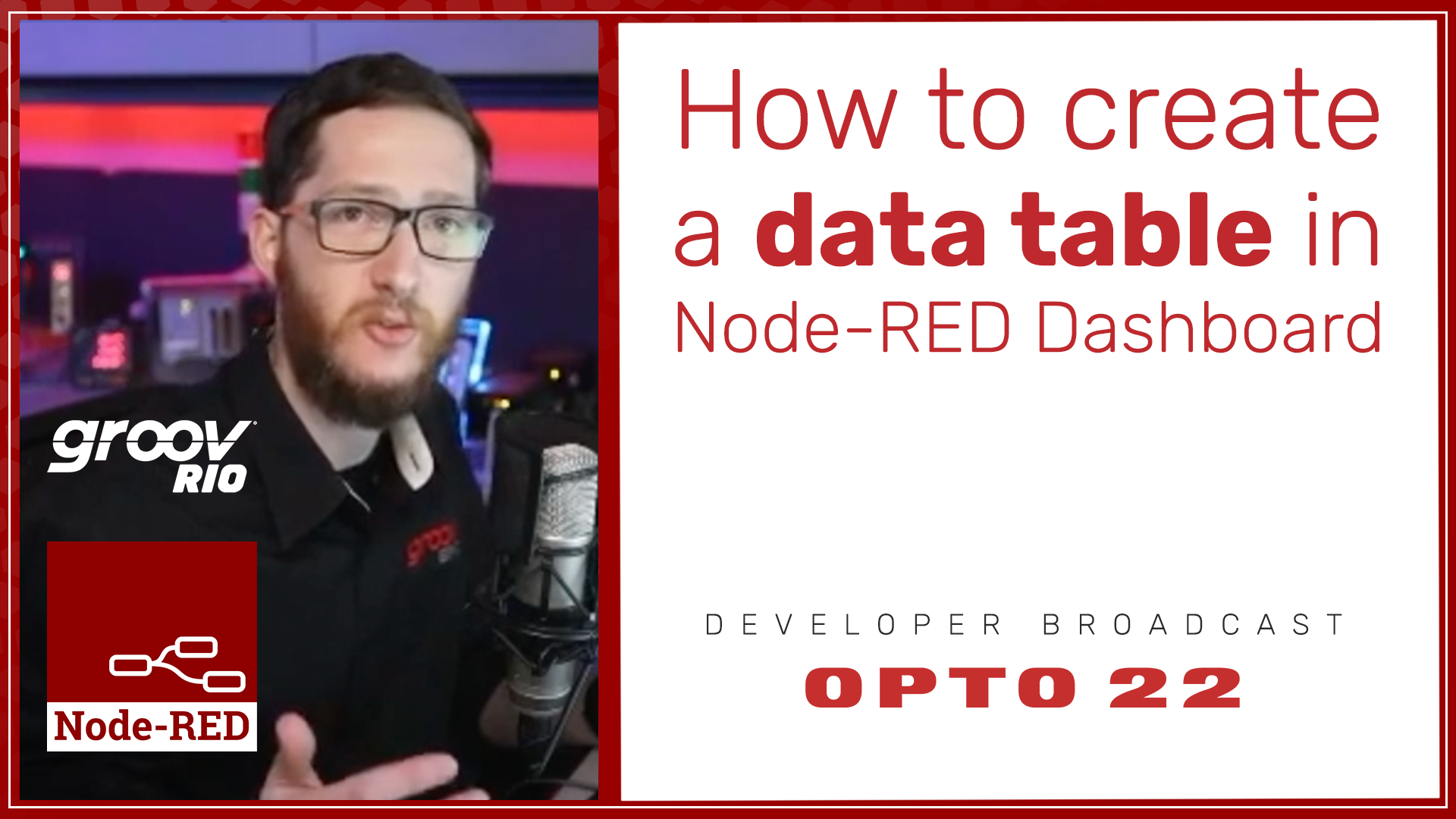

Next up in the Node-RED developer video series is a tutorial on adding data tables.

Did you know that you can install additional gadgets to the Node-RED dashboard? Terry Orchard returns to the OptoStudio to show off the features of the ui-table node. Learn how to install the table node package and configure different kinds of tables to fit your needs, complete with several examples using live, real-world data.

Read More

Topics:

Videos,

Node-RED,

groov EPIC,

groov RIO

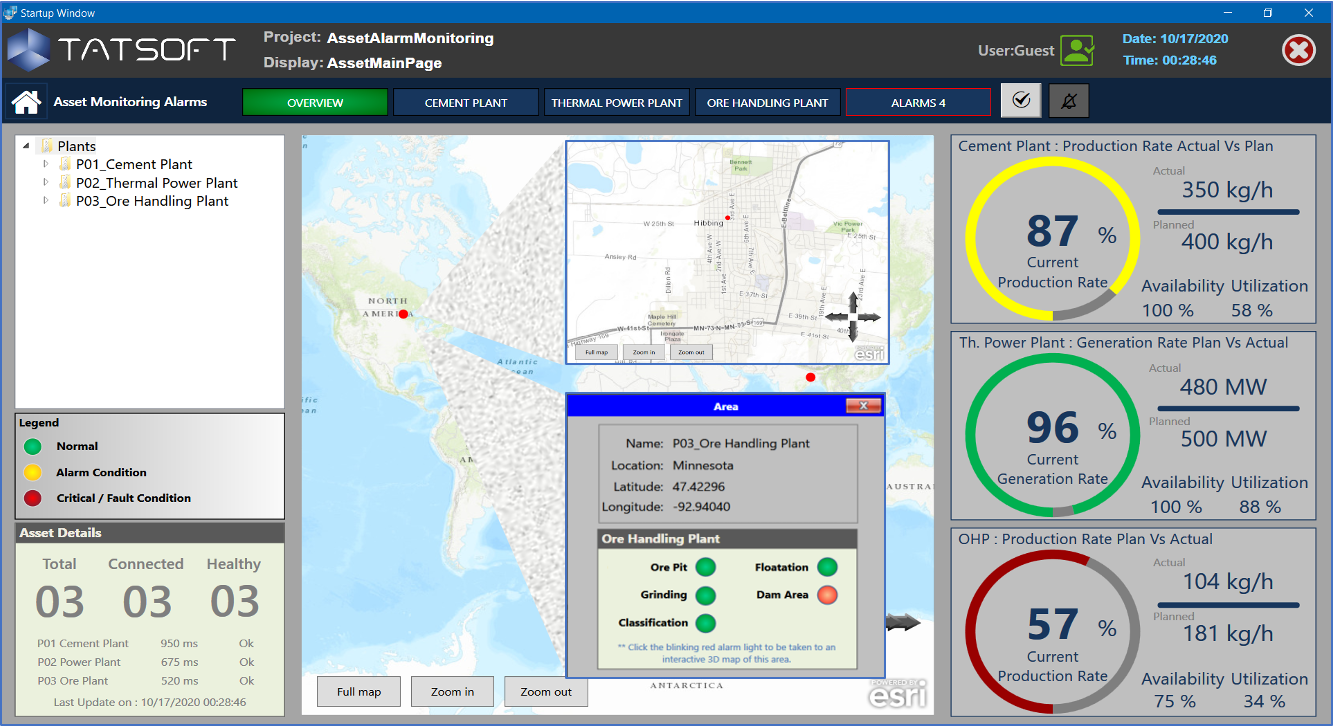

How can you deliver modern Industry 4.0 capabilities that still come in under budget? Harry McCollum of Tatsoft illustrates.

Today’s applications require more than a one-vendor approach. FrameworX by Tatsoft provides an open, extensible software platform as an alternative to the big control vendors. It includes everything you need to build world-class industrial applications at an affordable price: SCADA, HMI, MES, IIoT, mobile, dashboards, and more. With FrameworX, you can do it all without breaking the bank!

Read More

Topics:

groov EPIC,

groov RIO,

Art of the Possible,

open source,

Tatsoft

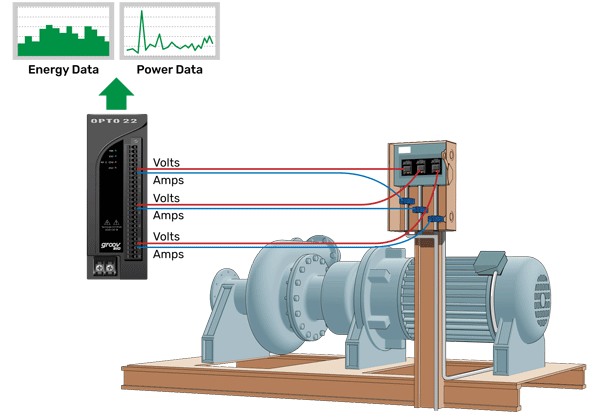

New website resources outline how to securely access and share your energy data.

Opto 22 gives you lots of options when it comes to helping you monitor your power and energy usage. The groov RIO EMU (energy monitoring unit) is an edge I/O module meant for easy distributed power and energy monitoring of one 3-phase load. Check out our previous announcements for all the details.

However, for monitoring multiple loads located near each other, and for a complete system including real-time control, groov EPIC with power monitoring modules might be the better choice.

But, you might have more questions about which is the right solution for you, why and how do you get started monitoring your machine health or energy data? And how do you do it securely?

Check out our new website resources for some guidance on these important energy topics.

Read More

Topics:

Energy management,

groov EPIC,

groov RIO,

power monitoring

Follow along in this new developer series video as Terry Orchard guides you through storing and passing data in a Node-RED flow.

What if you need to snapshot a message from a very specific part of a Node-RED flow?

For those of you who've been using the Node-RED programming tool or are just getting started, Terry's latest video provides some guidance on storing data. In a Node-RED flow, each node can add to, modify, or delete data in different ways.

Read More

Topics:

Videos,

Node-RED,

groov EPIC,

groov RIO

Watch the recorded presentation from the Spring 2022 CODESYS Tech Talk and see a real-world application using groov EPIC and the CODESYS runtime engine.

If you missed attending the virtual CODESYS Tech Talk earlier this month. now you can watch the Opto 22 presentation on demand.

Opto 22's Benson Hougland, Senior Application Engineer Garrick Reichert, and Allen Ray of Integrate Controls and Automation present a current CODESYS in-the-field application.

Read More

Topics:

Webinars,

CODESYS,

groov EPIC

Opto 22 UK distributor System Devices will be featuring groov EPIC and groov RIO at the upcoming Drives and Controls 2022 exhibition.

As the industrial automation industry returns to live, in-person events. we are pleased to announce that System Devices will be exhibiting at next week's Drives & Controls event in Birmingham (United Kingdom). System Devices is a long-time distributor of Opto 22 products as well as being certified IoT OptoPartners and trainers.

Read More

Topics:

Events & conferences,

groov EPIC,

OptoPartner,

groov RIO,

OptoChannel

-1.png)