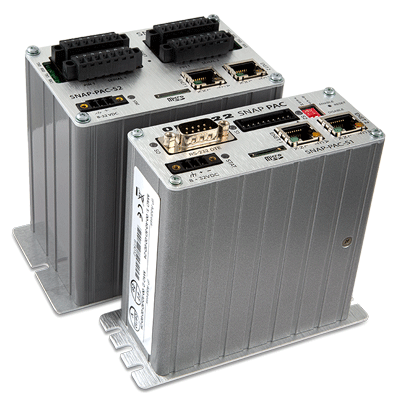

Here's the latest Code Samples and Tips contribution in our new OptoForum: an example of easier peer-to-peer communication between PAC controllers.

This example takes advantage of the new RESTful API in SNAP PAC hardware controllers (both the standalone S-series and the rack-mounted R-series).

Read More

Topics:

Internet of Things,

Tips,

IoT,

optonews,

PACs,

PAC Control,

API,

REST API,

RESTful server,

OptoNews 2016-08-31,

REST

Announcing groov 3.2 for the groov Box and groov Server for Windows.

In the new release:

- View system information in your groov interface. Show operators the time and date. Show groov admins the number of current user sessions, CPU usage, uptime, and more. The new System device includes these tags.

Read More

Topics:

groov,

Updates,

optonews,

OptoNews 2016-08-17

One of the world's largest automation events is headed to Chicago!

It's the international trade fair for industrial automation: Industrial Automation North America (IANA).

And here's an even bigger reason to attend: IANA is co-located with IMTS 2016, North America’s leading manufacturing technology trade show.

Read More

Topics:

Energy management,

Process control,

Food & beverage,

Discrete control,

Internet of Things,

IoT,

optonews,

PACs,

Events & conferences,

REST API,

OptoNews 2016-08-17

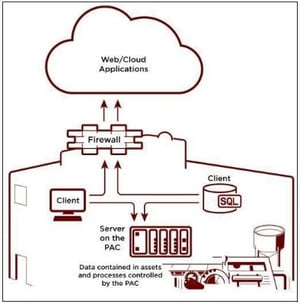

With the release of firmware R9.5a, Opto 22's rack-mounted and standalone SNAP PAC industrial controllers include a built-in RESTful API.

But what does that mean? What can you do with a RESTful API, and how does it fit into that Internet of Things (IoT) idea you've thought about?

Read More

Topics:

Internet of Things,

IoT,

optonews,

PACs,

REST API,

OptoNews 2016-08-17

A lot of our customers have gotten excited about the new HTTP/HTTPS server and RESTful API just added to Opto 22 SNAP PAC standalone and rack-mounted industrial controllers.

Why?

Because now your software developers can use the programming language of their choice to securely access data in the SNAP PAC—both I/O point data and data from any variable in your PAC Control strategy.

Read More

Topics:

Internet of Things,

Remote monitoring,

IoT,

optonews,

PACs,

REST API,

OptoNews 2016-08-03

How do you get fresh apples in March?

California Controlled Atmosphere (CalCA) knows the secret: strictly controlled storage.

CalCA builds produce storage systems for growers in California and all over the world. Each system must be flexible to accommodate fluctuating harvests and individual produce varieties.

Read More

Topics:

Case studies,

Videos,

Food & beverage,

optonews,

PACs,

OptoNews 2016-08-03

A lot of you post questions and share your expertise in the OptoForum. It's a great place to get advice from other Opto product users, explore new ways to solve a control problem, or share your sample code.

Now we're updating the forum platform to make it easier to use. Sometime in the next couple of weeks you'll see a major change.

Read More

Topics:

Insider,

Updates,

optonews,

OptoNews 2016-08-03

Last OptoNews you heard about all the new features in PAC Project 9.5 and SNAP PAC firmware 9.5, both just released.

The most exciting new features are the HTTP/HTTPS server and RESTful API, giving you secure access to I/O point and variable data in your PAC controller.

These developer- and IoT-ready features are free—all you need to do is update your firmware.

But updating PAC controller firmware on a running system can pose a problem.

Read More

Topics:

Updates,

Tips,

optonews,

PACs,

PAC Project,

Firmware,

PAC Control,

OptoTagPreserve,

OptoNews 2016-08-03

I'm extremely excited about the new capabilities of the 9.5 firmware and, in particular, the new RESTful interface (REST API and HTTP/S server) for SNAP PAC controllers. I have several PACs throughout my home for various tasks like lighting, A/C, irrigation, energy management, monitoring, and surveillance. The new RESTful interface allows me to take my home automation system to completely new levels, including interacting with my other home automation/IoT products, like my Nest thermostats, smoke alarms, and NestCams; my Philips Hue lighting; my Wemo switches; and much more.

This post isn’t about home automation, however. It’s about getting the firmware upgrade done and configuring the HTTP/S RESTful server. And in doing so, it was important to me (and my application) that I preserved the persistent control system variables used in my control strategies. So...the following are the steps I took to upgrade my firmware while preserving important data and getting started with REST.

Read More

Topics:

PACs,

Firmware,

PAC Control,

API,

REST API,

RESTful server,

PAC Manager,

OptoTagPreserve,

REST

Available now. Announcing the new PAC Project and firmware R9.5a releases. Included:

- Many new features you've asked for

- Support for two new I/O modules

- A brand-new HTTP/HTTPS server and REST API to make integration, data exchange, and Internet of Things (IoT) applications

Read More

Topics:

Internet of Things,

Updates,

IoT,

optonews,

PACs,

New products,

Integrators,

PAC Project,

OptoNews 2016-07-20