If you've used Opto 22 products for a long time, you may very well have some colorful G4 digital I/O modules in a panel somewhere. They were probably installed back in the 1990s.

Still reliably monitoring sensors and activating outputs, these G4s are likely the workhorses of your automation system. Why would you ever want to replace them?

Read More

Topics:

Discrete control,

optonews,

Migration,

I/O,

PAC Project,

Optomux,

OptoNews 2015-11-04

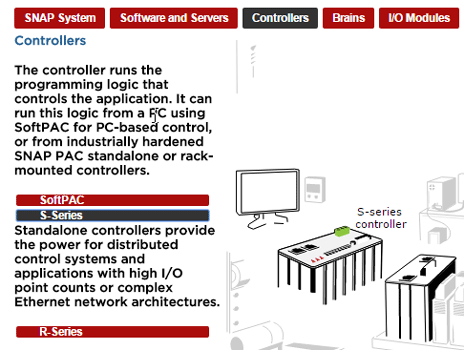

Choose the software, controllers, I/O, and more for your application, with help from our new interactive demo about SNAP PAC System components.

You'll find answers to questions like these:

Read More

Topics:

optonews,

PACs,

I/O,

PAC Project,

OptoNews 2015-11-04

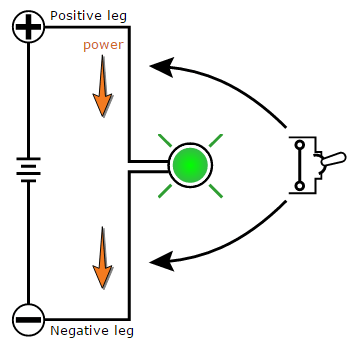

We talked about sinking and sourcing in a previous OptoNews tech tip.

But it's a subject that causes a lot of confusion, so it's worth revisiting.

Sinking and sourcing basically refer to the two methods of wiring a digital DC circuit.

Read More

Topics:

Discrete control,

Tips,

optonews,

I/O,

OptoNews 2015-11-04

Sinking or Sourcing?

Let’s take a quick look at the topic of sinking and sourcing outputs.

Where did the difference come from, and where does it matter in automation?

Quick answer: you often have to choose the correct module because the device you are wiring requires either a sink or source. For example, if you have a prebuilt electrical cabinet, it may be wired using a common positive or a common negative method. Thus you HAVE to choose the correct digital output module for the way the panel is wired.

Read More

Topics:

PLCs,

Electronics,

Tips,

IoT,

Machine builder,

OEM,

I/O

A firmware update is now available for E1 and E2 brain boards. If your current firmware is R1.1d or R1.1e, you'll want to install the new firmware. See the firmware readme for details.

For those of you not familiar with E1s and E2s, they are serial- and Ethernet-based brain boards typically used with G1 or G4 I/O systems. The E1 is for digital I/O and the E2 for analog I/O.

We designed the E1 and E2 as drop-in replacements for older serial-based B1 and B2 brain boards.

Read More

Topics:

optonews,

Migration,

I/O,

Optomux,

OptoNews 2015-10-21

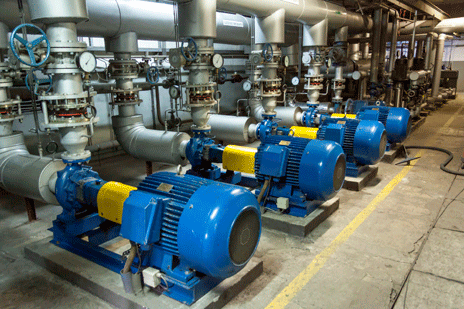

Let's say you have four pumps available, and you don't run them all at once. When it's time to start one, you want to choose the one with the least wear.

You can decide which one to start by comparing the total amount of time each pump has run. That's a job for a totalizer.

Read More

Topics:

Tips,

optonews,

PACs,

I/O,

PAC Project,

OptoNews 2015-10-21

Confused about sinking and sourcing in DC circuits?

Want to find out which digital output module to use in a DC circuit?

Manufacturers label their DC outputs in different ways. This new animated demo defines sinking and sourcing and shows you which type of Opto 22 output module to use, depending on your application.

Read More

Topics:

Discrete control,

optonews,

Training,

I/O,

OptoNews 2015-10-07

When you turn on an output, do you set a flag and then check it to see the output's status before turning the output on again?

Or do you just turn it on without checking?

Is setting a flag a good way to speed up the program and avoid tying up the network with unnecessary communications to I/O?

Or does it just add a lot of extra variables and decision blocks that make debugging and maintenance harder?

Read More

Topics:

Discrete control,

Tips,

optonews,

PACs,

I/O,

PAC Project,

OptoNews 2015-09-23

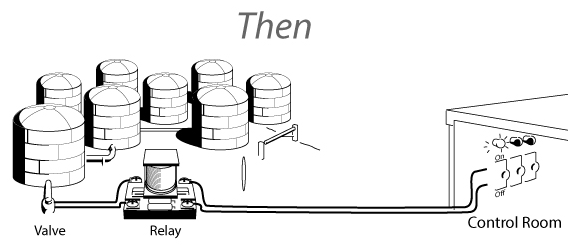

The Case for Intelligent I/O Systems.

The automation PC is located in the control room, and the dump valve is on the other side of the tank farm wired to a remote I/O cabinet, all connected over an Ethernet network.

The IT guys are working on the network, and they say it may take a few days to track down the intermittent cable. But hey, in the meantime, they say that it mostly works…

That answer might be sufficient for watching YouTube, but it is just not going to cut it for controlling that valve.

What do you do?

Read More

Topics:

Discrete control,

PLCs,

Remote monitoring,

Tips,

IoT,

PACs,

OEM,

I/O

Have a HART

Communicate with your smart HART® (Highway Addressable Remote Transducer) devices with these two HART SNAP I/O modules—an input and an output.

HART is the most widely used digital communications protocol in process automation, so you'll find plenty of devices you can monitor and talk to using these modules.

Both I/O modules have channel-to-channel isolation and carry a lifetime warranty.

Read More

Topics:

Energy management,

Process control,

optonews,

I/O,

HART,

OptoNews 2015-08-26